Printed fabric hand sample continuous heater

A heating machine and fabric technology, applied in printing machines, general parts of printing machinery, printing, etc., can solve the problems of uneven heating of printed fabrics, insufficient color fixation, easy fading, color differences, etc., to achieve appearance quality and product quality assurance , small color difference, good color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific examples.

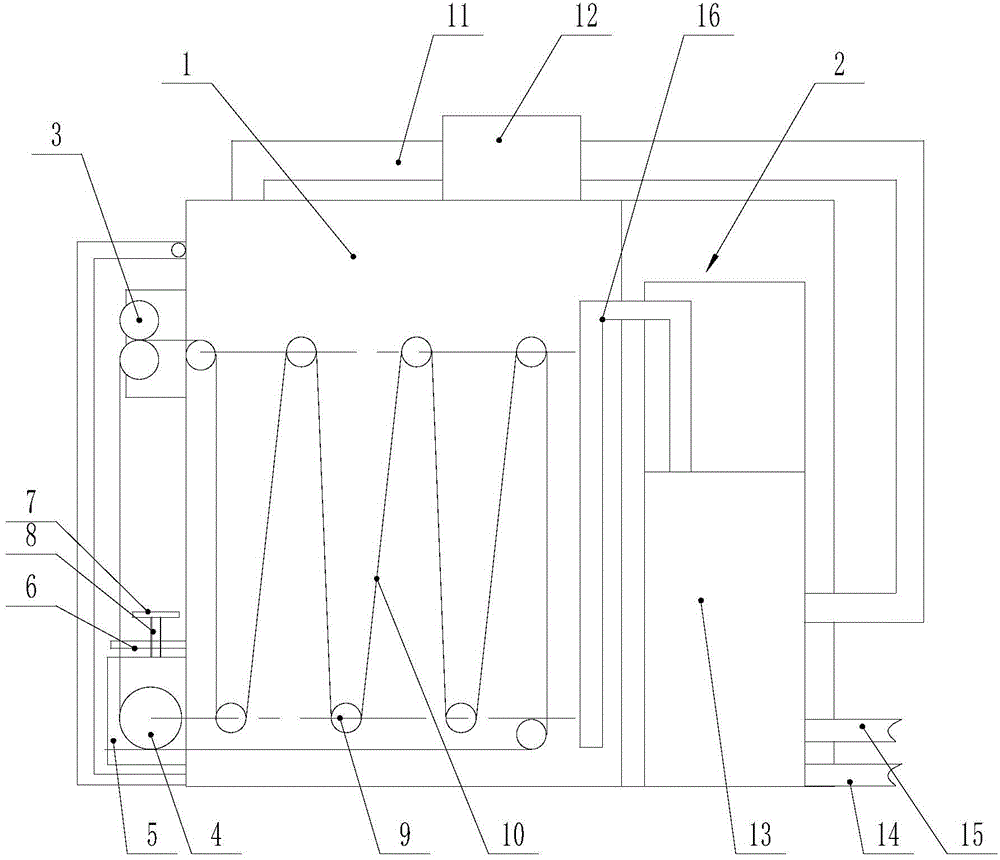

[0018] Such as figure 1 As shown, a continuous heating machine for printed fabric samples includes a heating device and a steam generating device 2. The heating device includes a heating box 1, several inner transition rollers 9 installed in the heating box 1, and The upper transition roller 3 and the lower driving roller 4, the circulating conveyor belt 10 which circulates is installed between the several inner transition rollers 9, the upper transition roller 3 and the lower driving roller 4; the steam generating device 2 includes a heating element A steam generating chamber 13, which is fixed on the side wall of the heating box 1, stores water to be evaporated in the steam generating chamber 13, and the steam generating chamber 13 is provided with a water supply port 15, a steam outlet, and a water discharge port 14, The steam outlet is connected with the inner cavity pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com