Engine oil filter structure

An oil filtration and oil technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of increasing the pressure loss of the lubrication system, affecting the service life of the oil filter, etc., to increase the mission life, simple structure, Life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

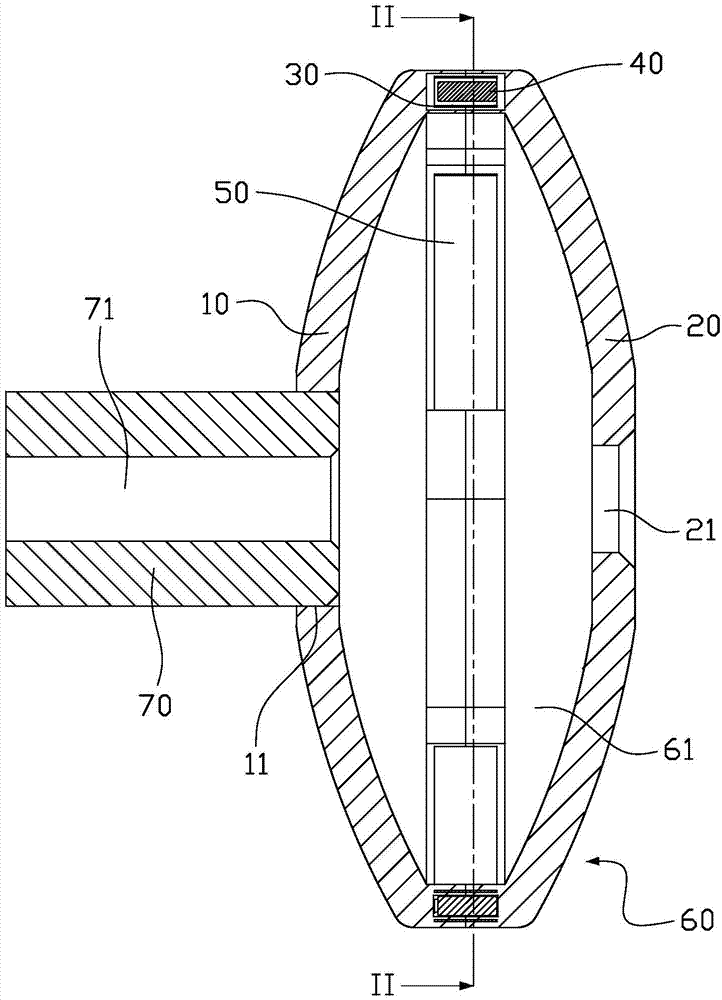

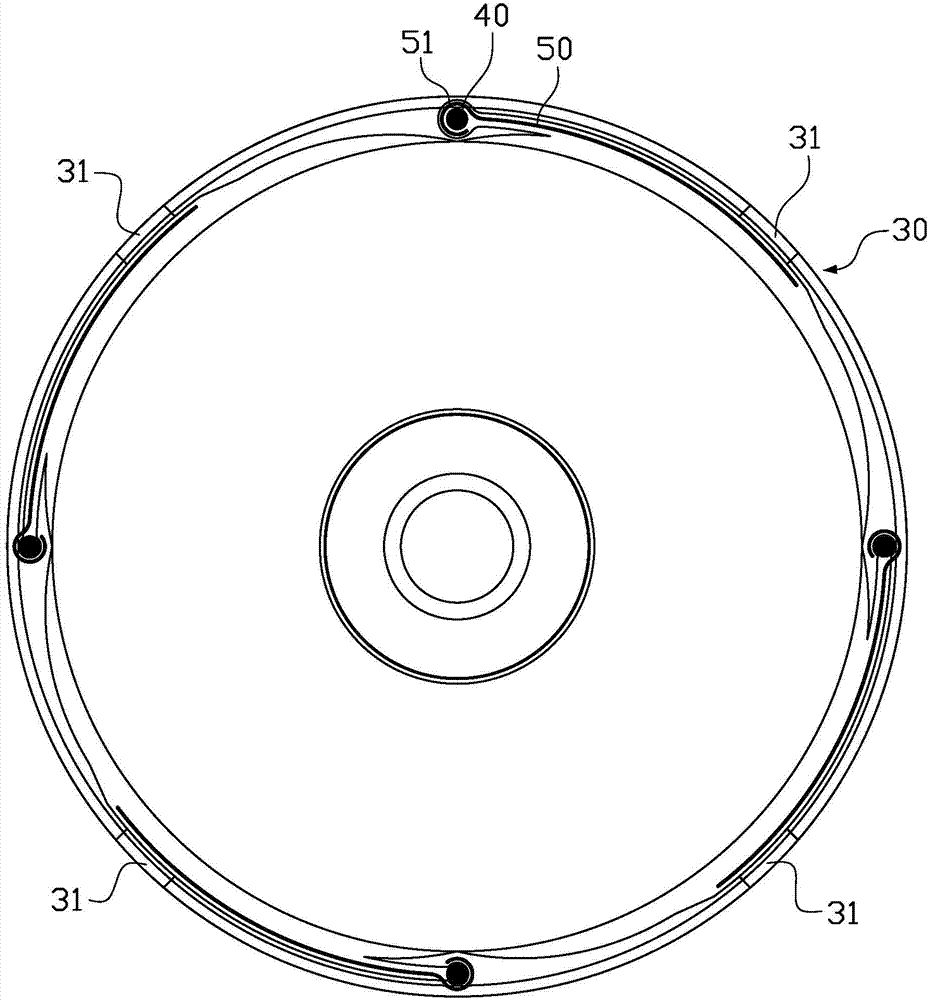

[0018] See figure 1 with figure 2 , the embodiment of the present invention provides an oil filter structure, which is arranged between the crankshaft 70 of the automobile and the oil pump (not shown in the figure), and is used to remove impurities such as iron filings in the engine oil, wherein the crankshaft 70 is provided with a center Oil hole 71. The oil filtering structure provided in this embodiment includes a first housing 10 , a second housing 20 , a plurality of pin bodies 40 and a plurality of valve plates 50 .

[0019] The first housing 10 is fixedly sleeved on the end of the crankshaft 70 . The first housing 10 is fixedly connected with the second housing 20 to form a rotating housing 60 , and an oil storage cavity 61 is formed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com