Device for curved surface printing and working method thereof

A curved surface printing and printing device technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems that curved surface printing cannot be realized, and achieve the effect of realizing automatic connection, improving printing efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

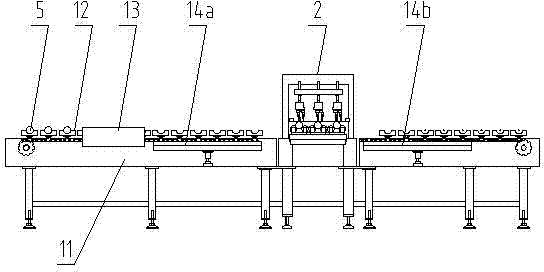

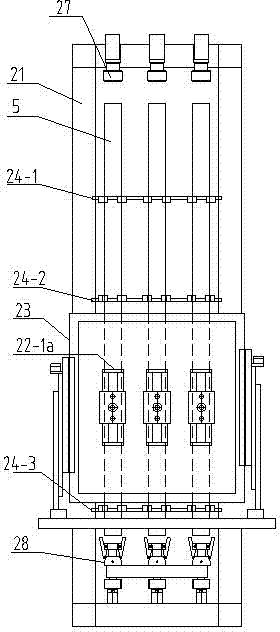

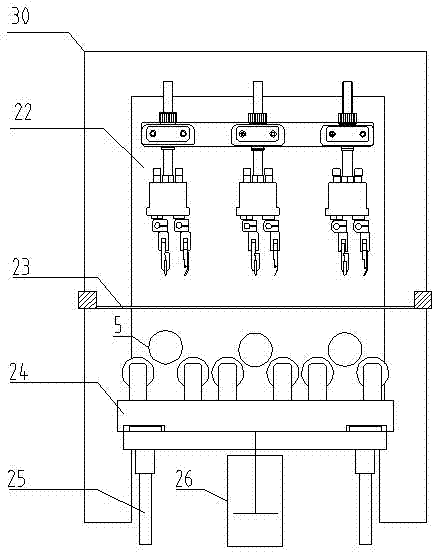

[0038] Such as Figure 1-6 As shown, the device for curved surface printing in this embodiment is used for curved surface printing, including a frame 11, a conveying device 1, a multi-station automatic curved surface screen printing machine 2 and an ink curing device 3, the conveying device 1, Both the multi-station automatic curved surface screen printing machine 2 and the ink curing device 3 are arranged on the frame 11 . The workpiece 5 is sent to the multi-station automatic curved surface screen printing machine 2 through the conveying device 1, and the automatic printing of multiple workpieces at one time is realized through the multi-station automatic curved surface screen printing machine 2, and the printed workpiece 5 is sent by the conveying device 1 The workpiece 5 is transported to the ink curing device 3, where the ink is cured on the workpiece 5, and then the workpiece 5 that has been printed and cured is transported to the next process by the conveying device 1. ...

Embodiment 2

[0059] The structure of the device for curved surface printing in this embodiment is basically the same as that of the device for curved surface printing in Embodiment 1, with two differences:

[0060] The first difference is that the printing mechanism includes two printing heads evenly arranged on the horizontal support rods. By setting two printing heads, two workpieces can be printed simultaneously in one assembly line operation, which improves the printing efficiency.

[0061] The second point of difference is that the supporting wheel group is divided into a front supporting wheel group and a rear supporting wheel group, which are respectively arranged at the front and rear of the workpiece bracket. The supporting roller group is used to support the workpiece and position the workpiece, and also cooperate with the front positioning device and the rear positioning device to realize the printing positioning.

[0062] The third difference is that the positioning device is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com