Mine Anchor Cable End Shaping Device

An end shaping and anchor cable technology, which is used in mining equipment, bolt installation, earthwork drilling, etc., can solve the problems of small initial anchor force, long exposed steel strands, and low coal mine tunnels, so as to reduce roof fall accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

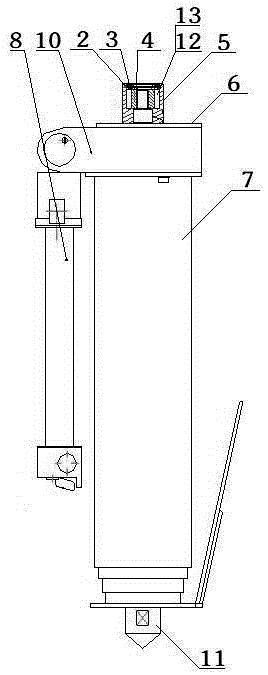

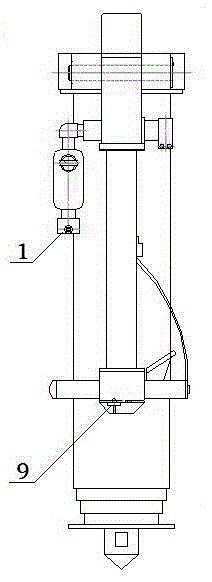

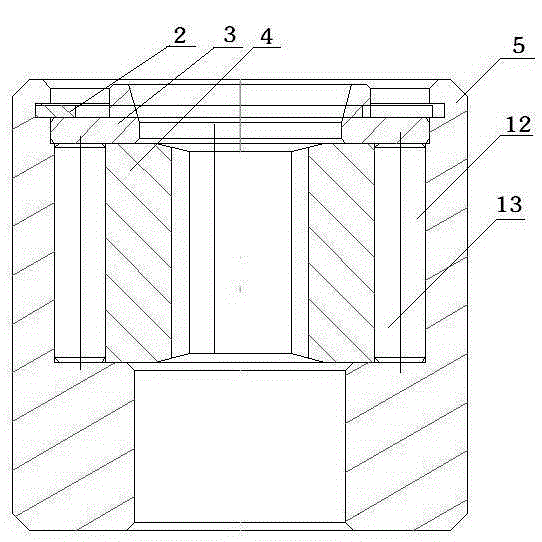

[0012] A cable end shaping device for mining, including an air inlet joint 1, an air leg 7, an operating arm 8, an air leg switch 9, a head seat 10 and a lower ejector rod 11, and is characterized in that: the head seat 10 is provided with a Base 6, the base 6 is provided with a broken strand pressing head, and the described strand breaking pressing head is composed of an installation body 5, a clamping sleeve 4, a pressure sleeve 3, a retaining ring 2 and a fixed pin 12, and the installation body 5 is fixed on On the base 6, the clamping sleeve 4 is arranged in the mounting body 5, the clamping sleeve 4 is provided with a pressure sleeve 3, the pressure sleeve 3 is provided with a retaining ring 2, the clamping sleeve 4 is provided with a fixed pin groove 13, and the fixed pin 12 The clamping sleeve 4 and the installation body 5 are fixed together, and the inner ring 14 of the clamping sleeve 4 is provided with an arc-shaped groove 15 .

[0013] When in use, connect the air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com