Prick and bursting resistance improved tire structure

A technology for improving structure and tires, applied in vehicle parts, tire parts, transportation and packaging, etc., can solve problems such as air leakage, life-threatening car accidents, and inability to drive, and achieve the effect of ensuring driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

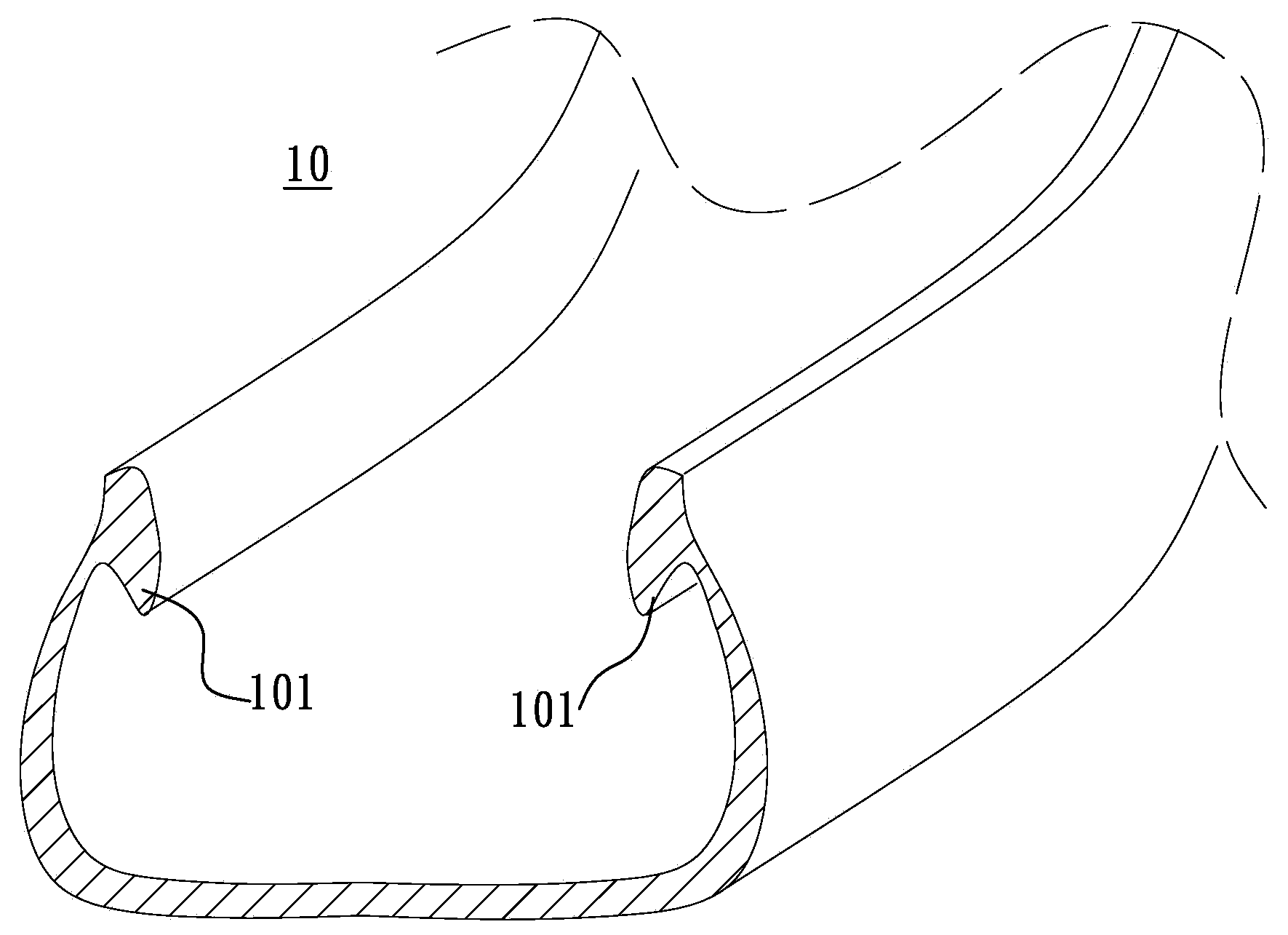

[0050] The invention is an improved anti-blade and anti-explosion structure for tires, ( figure 1 ) It mainly includes a tire 10, the inner edge of both sides of the inner ring is protruded with annular protruding ring hooks 101, and the interlayer is provided with curtain reinforcement.

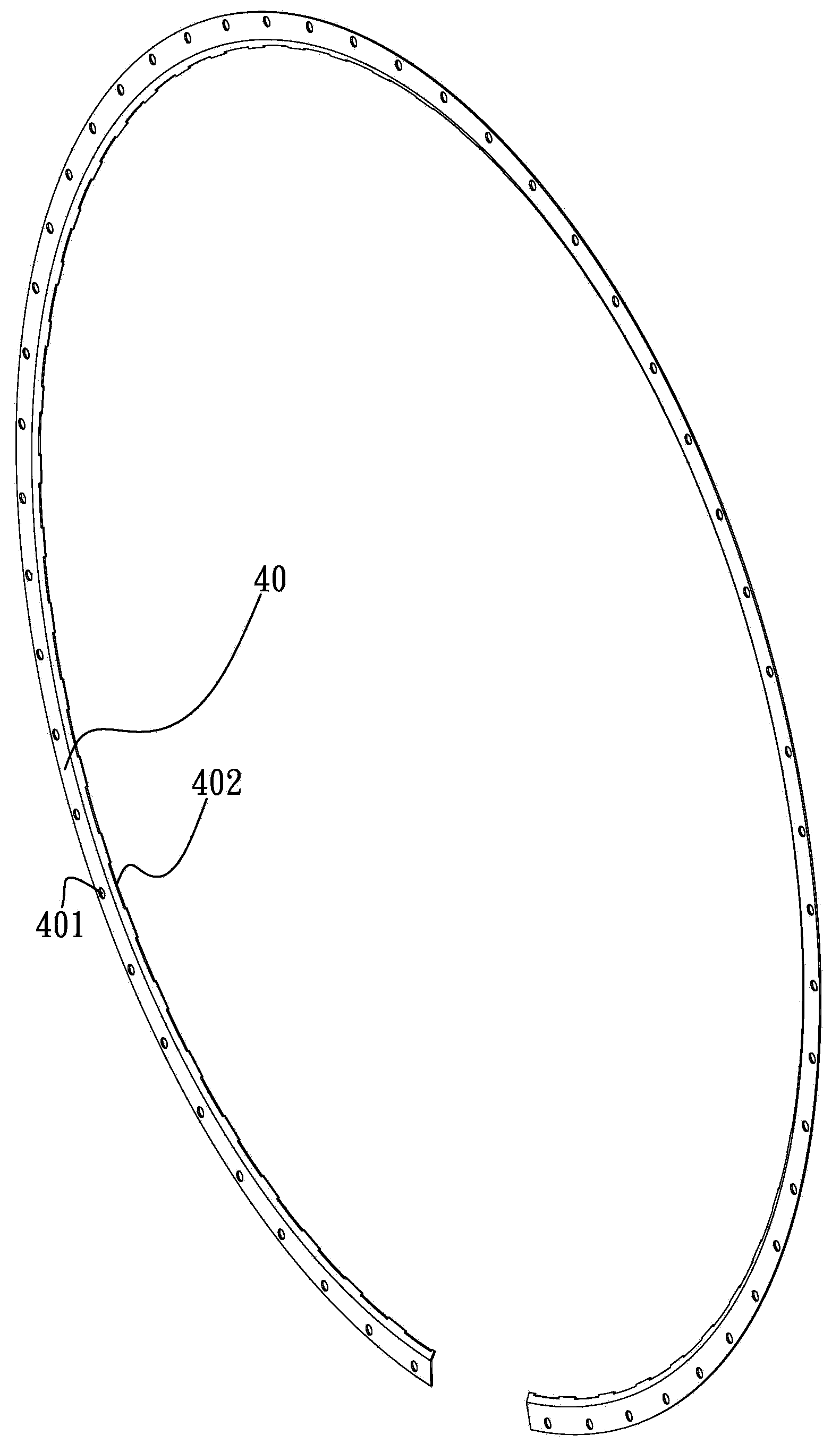

[0051] Two tandem C-shaped cables 40 (see figure 2 ), which is C-shaped and provided with a plurality of perforations 401 and grooves 402 .

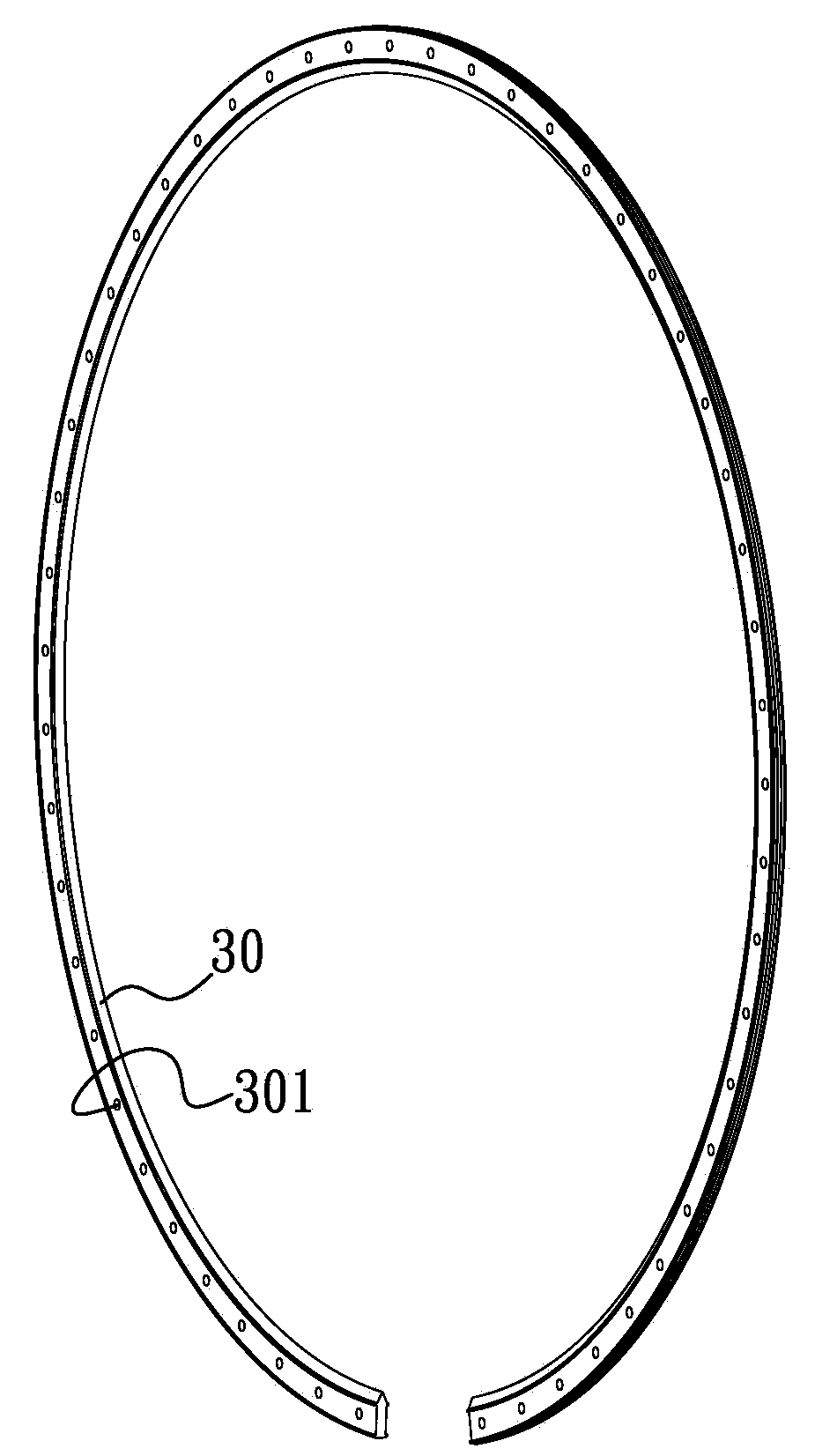

[0052] A series of C-shaped cables 30 ( image 3 ), which is C-shaped and provided with a plurality of perforations 301 .

[0053] A series of trimmers 50, ( Figure 8 ) is mainly a piece with a plurality of shaft holes 501, and a top piece 502 protrudes from the top edge of the piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com