Load simulator driven by two motors

A load simulator, dual-motor drive technology, applied in simulators, simulation devices and instruments of space navigation conditions, etc., can solve the problems of polluting the environment, bulky, affecting the rapidity of the system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below in conjunction with accompanying drawing:

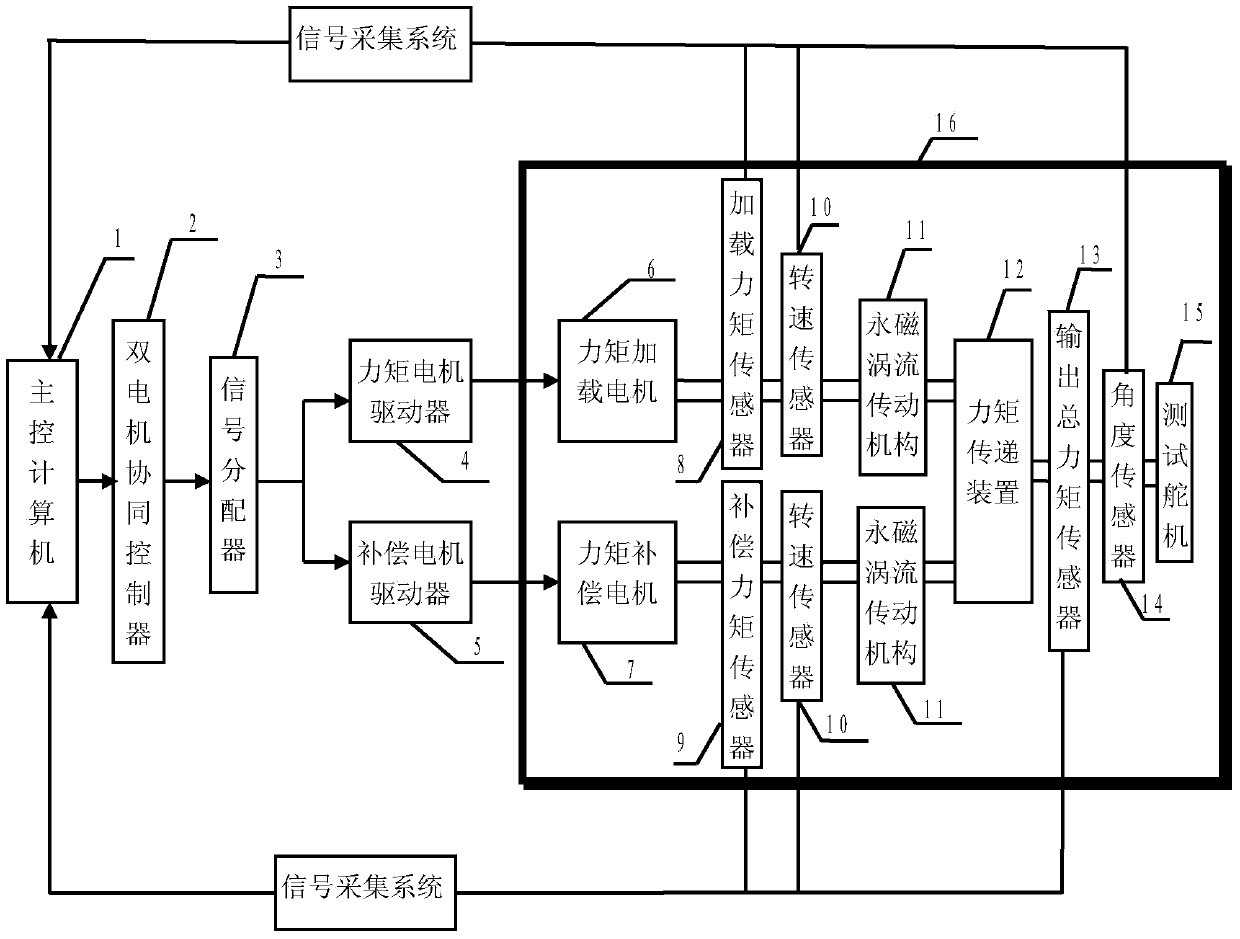

[0015] Such as figure 1 As shown, the load simulator device driven by dual motors consists of a main control computer 1, a signal acquisition system, a dual motor cooperative controller 2, a signal distributor 3, a torque motor driver 4, a compensation motor driver 5, a torque loading motor 6, and a torque compensation Motor 7, loading torque sensor 8, compensation torque sensor 9, two speed sensors 10, two permanent magnet eddy current transmission mechanisms 11, torque transmission device 12, output total torque sensor 13, angle sensor 14, test steering gear 15 and test loading Taiwan 16. The dual-motor cooperative controller is connected to the signal distributor, the signal distributor is connected to the torque motor driver and the compensation motor driver, the torque motor driver is connected to the torque loading motor, and is used to drive the torque loading motor, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com