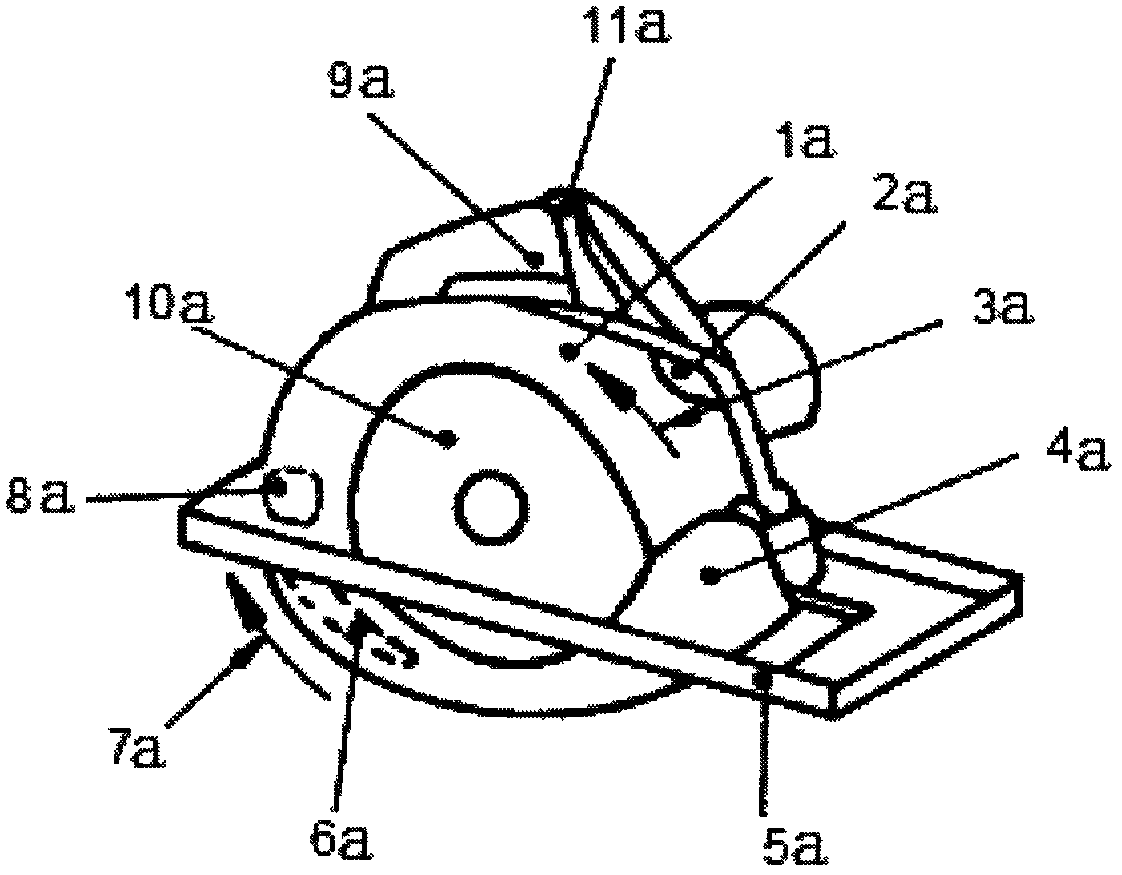

Electric circular saw shield rebound test device

A rebound test and saw guard technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that the circular saw guard cannot fully rebound and return, and the circular saw guard cannot be completely pulled. It can improve the accuracy and applicability, optimize the structure, and facilitate the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

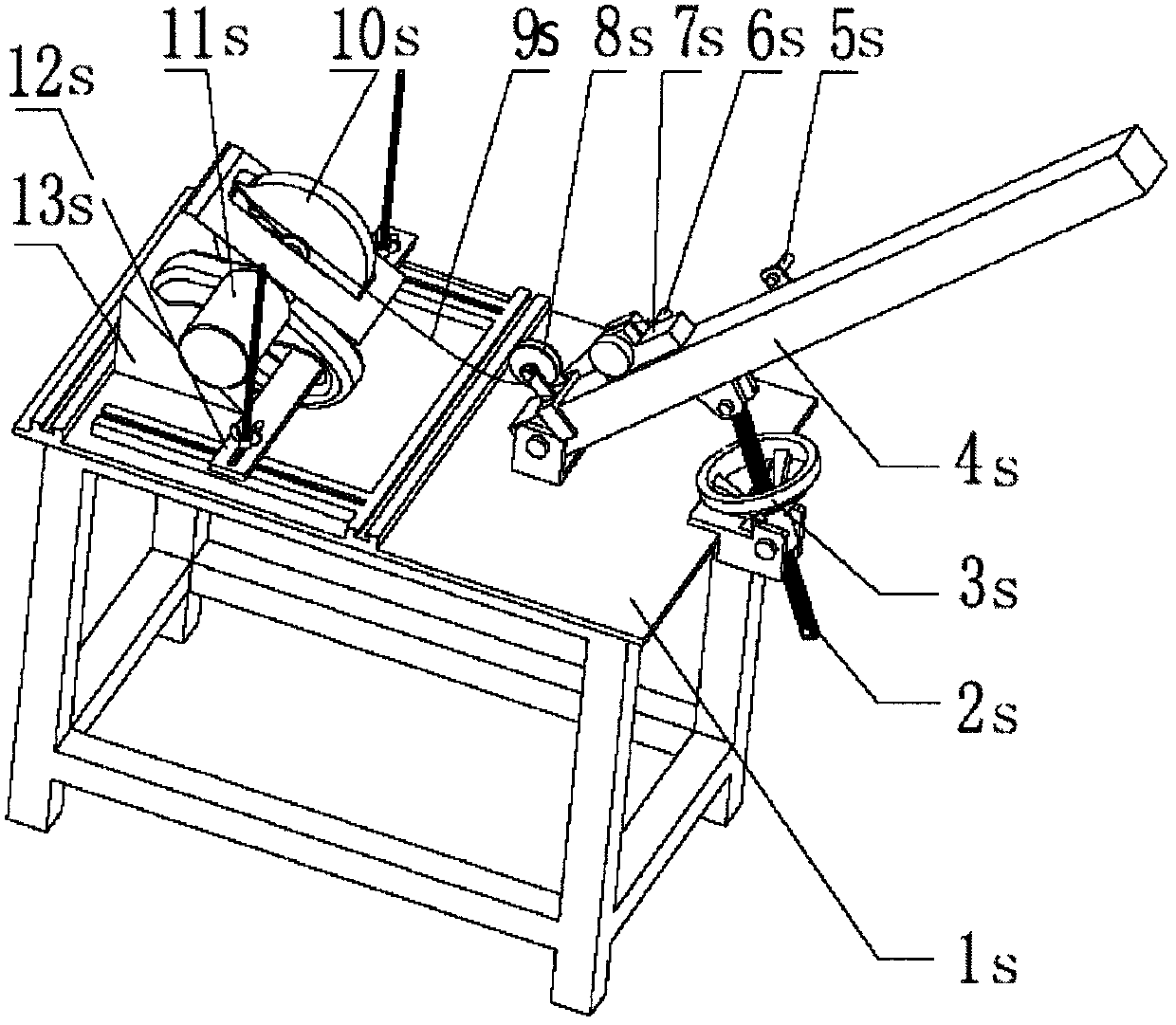

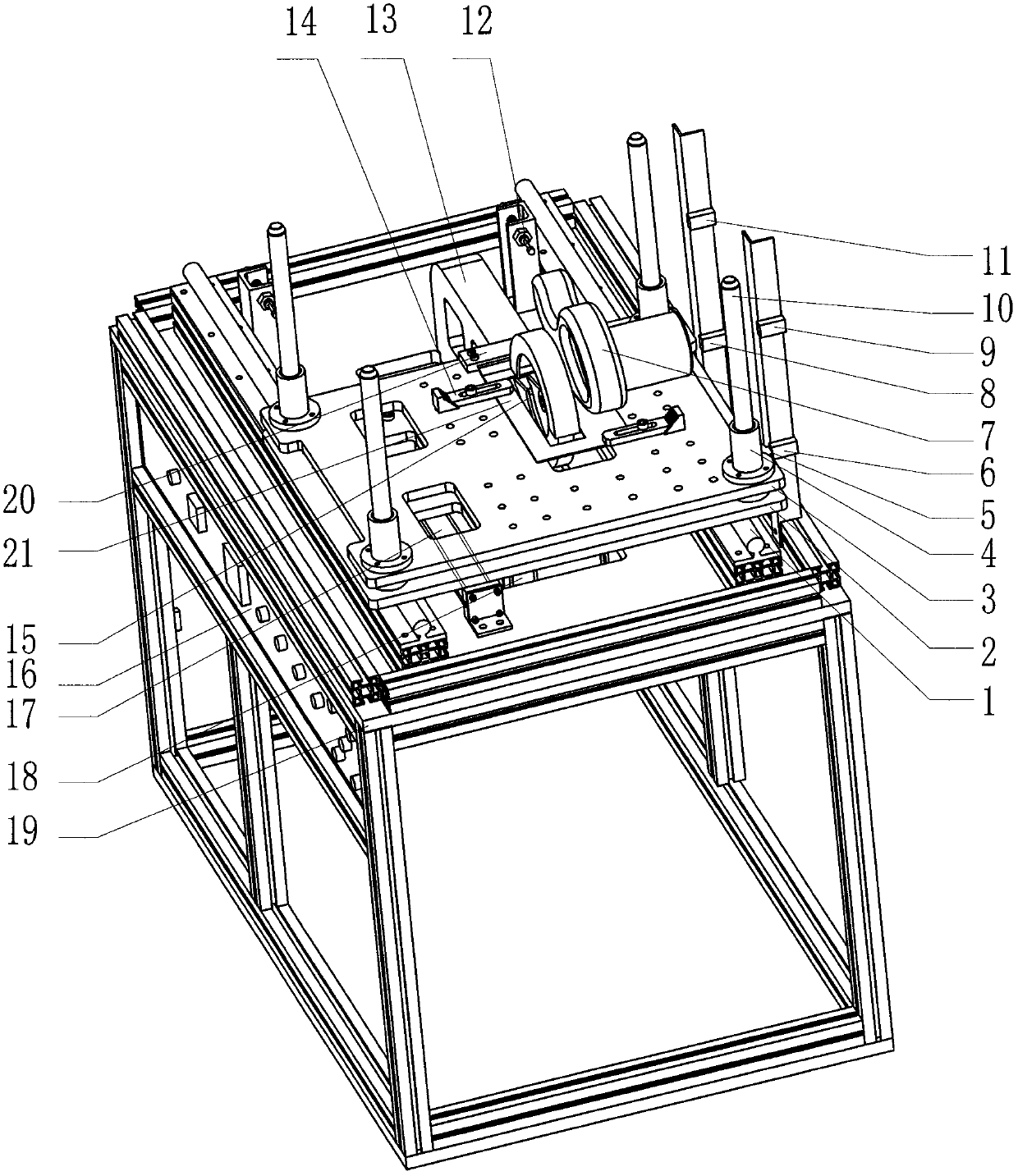

[0037] The following is attached with the manual image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 The present invention is described in detail.

[0038] Such as image 3 The initial state shown is a

[0039] The test sample 7 is placed on the sample lifting support platform 3 and fixed to the support platform 3 by the sample fixing pressing block 14 . The sample lifting and supporting platform part 3 cooperates with four lifting sliding bearings 4, four lifting rods 10 and the lower bottom plate slider 2, and is jointly fixed in the horizontal guide rail 1 of the equipment bottom plate 19. A horizontal telescopic cylinder 17 and a vertical telescopic cylinder 18 are installed on the equipment base plate 19 in addition. The horizontal telescopic cylinder 17 works in cooperation with the horizontal guide rail 1 to make the test sample 7, the sample lifting support platform 3, and the lower floor slide block 2 move in the horizontal direction together. The vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com