Screw-nut transmission device for steel gate

A technology of screw nut and transmission device, which is applied in water conservancy projects, sea area engineering, coastline protection, etc. It can solve problems such as inconvenient lubricating oil, wear of the screw and nut transmission pair, and seizure of the screw and nut transmission pair. To achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

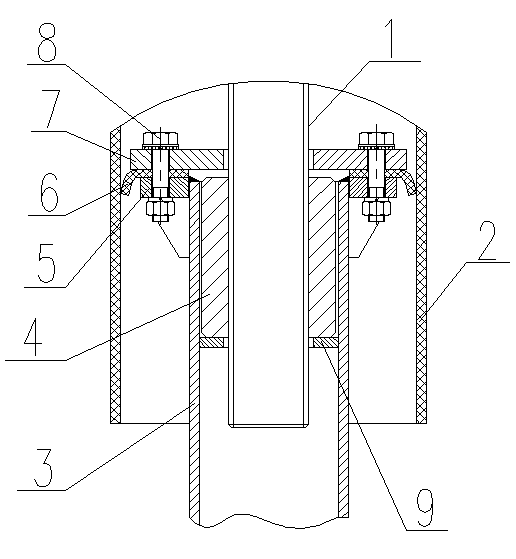

[0009] A screw nut transmission device for a steel gate, comprising a screw rod 1, a sleeve 2 is arranged outside the screw rod 1, a connecting rod 3 is arranged at the lower end of the screw rod 1, and 4 sets of nuts are arranged in the inner cavity of the upper end of the connecting rod 3 Connected to the lower end of the screw rod 1, the upper end of the connecting rod 3 is provided with a flange 5 on the outer circle, the upper end of the flange 5 is provided with a gasket 6, and the upper end of the gasket 6 is provided with a pressure plate 7 and connected to the flange 5 through bolts 8; The inner cavity of the rod 3 is provided with a baffle plate 9 located at the lower end of the nut 4, and the baffle plate 9 is provided with a through hole for the threaded mandrel 1 to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com