Rake-toothed biomass material conveying device

A conveying device and biomass technology, which is applied in the field of machinery, can solve the problems of large manpower, large floor space, and low efficiency, and achieve the effects of saving construction costs, reducing losses, and reducing the number of installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

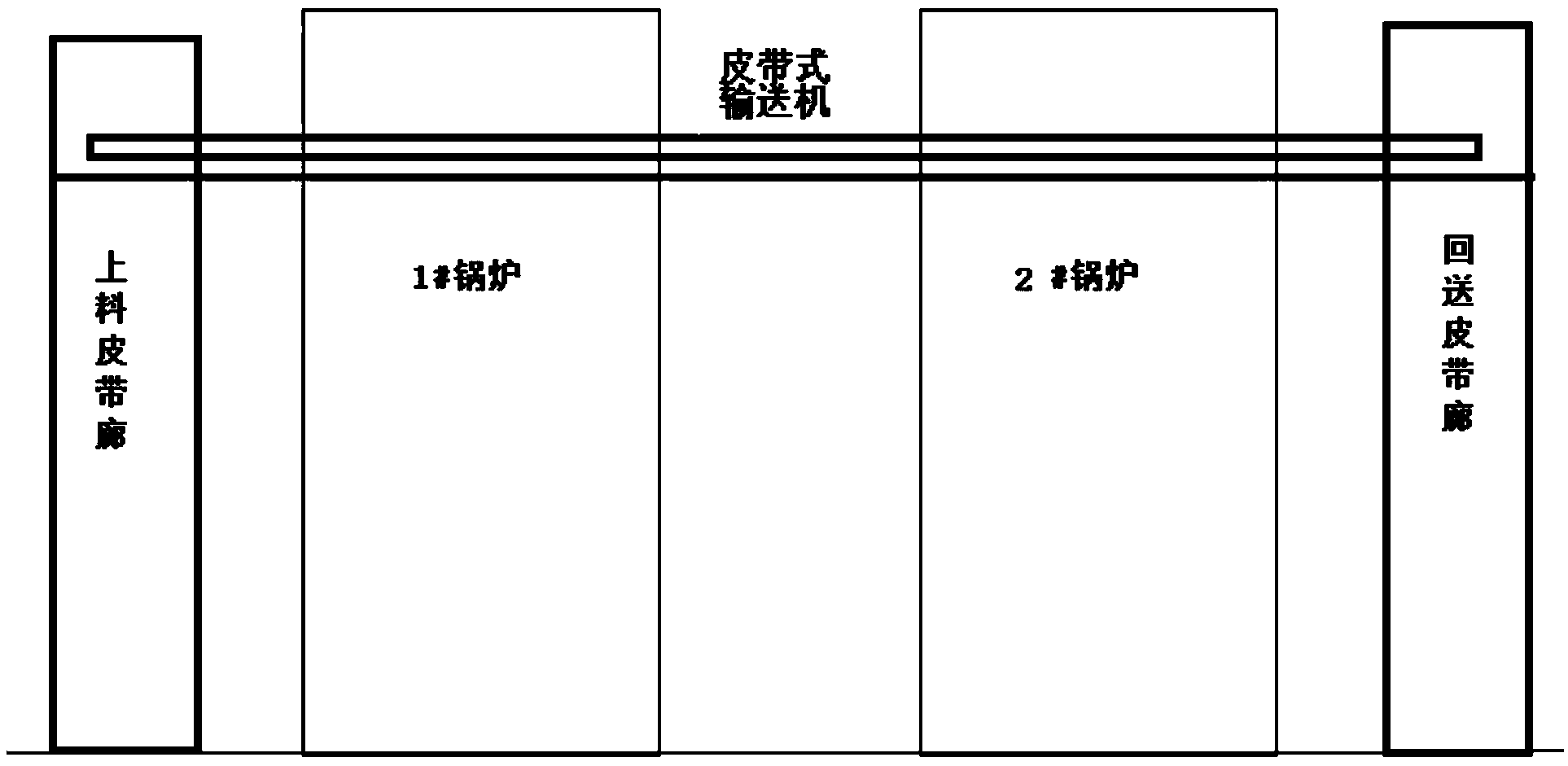

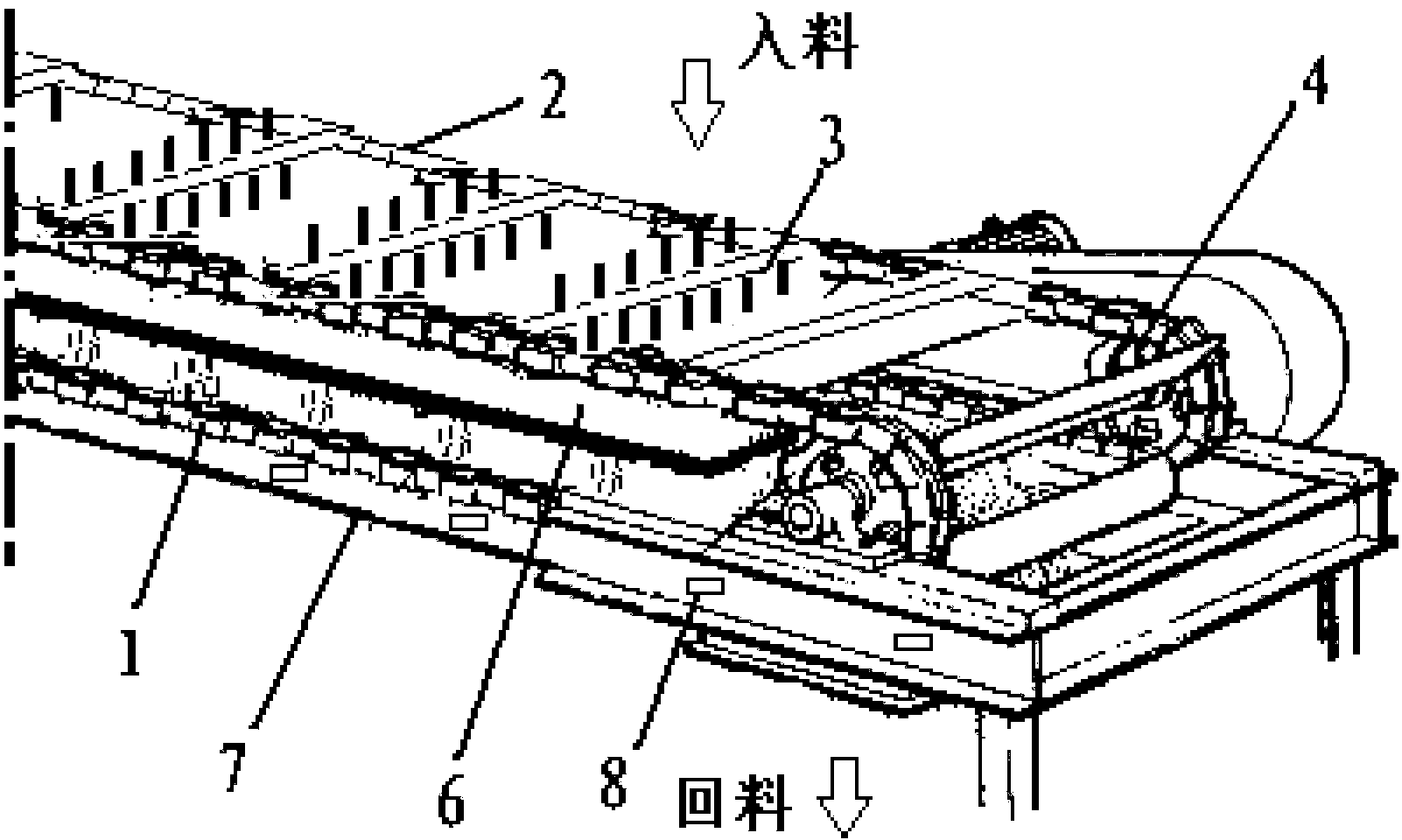

[0089] In combination with the above-mentioned embodiments, a specific example is used to illustrate the working process of a rake-tooth biomass material conveying device. The specific workflow can be as follows:

[0090] S1. The feeding belt corridor adds biomass materials to the intermediate partition 6 .

[0091] S2. The driving device provides power to the drive shaft 4, and the drive shaft 4 drives the first traction chain 1, the second traction chain 2 and the transmission shaft 5 to rotate. The rake teeth 3 fixed on the first traction chain 1 and the second traction chain 2 move the biomass material on the intermediate partition 6 along with the movement of the first traction chain 1 and the second traction chain 2 .

[0092] S3. The biomass material moving to the top of the intermediate partition 6 falls on the lower bottom plate 7 .

[0093] S4. The rake teeth 3 push the biomass materials falling on the lower bottom plate 7 to move (the movement direction of the rak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com