Box assembly, automatic gearbox and automobile

A technology of components, boxes, applied in the direction of gearboxes, transmission parts, elements with teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

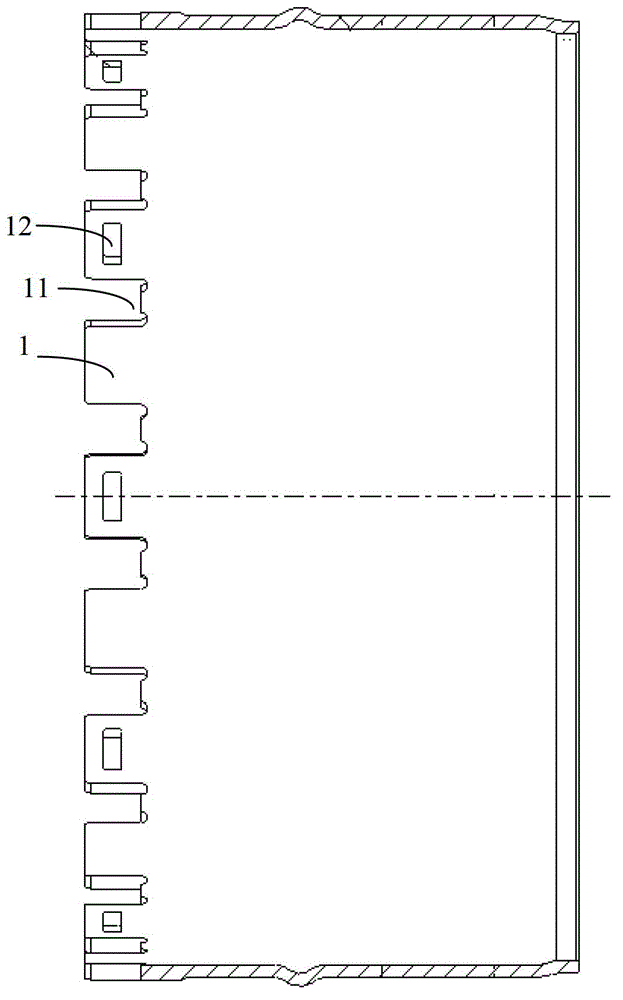

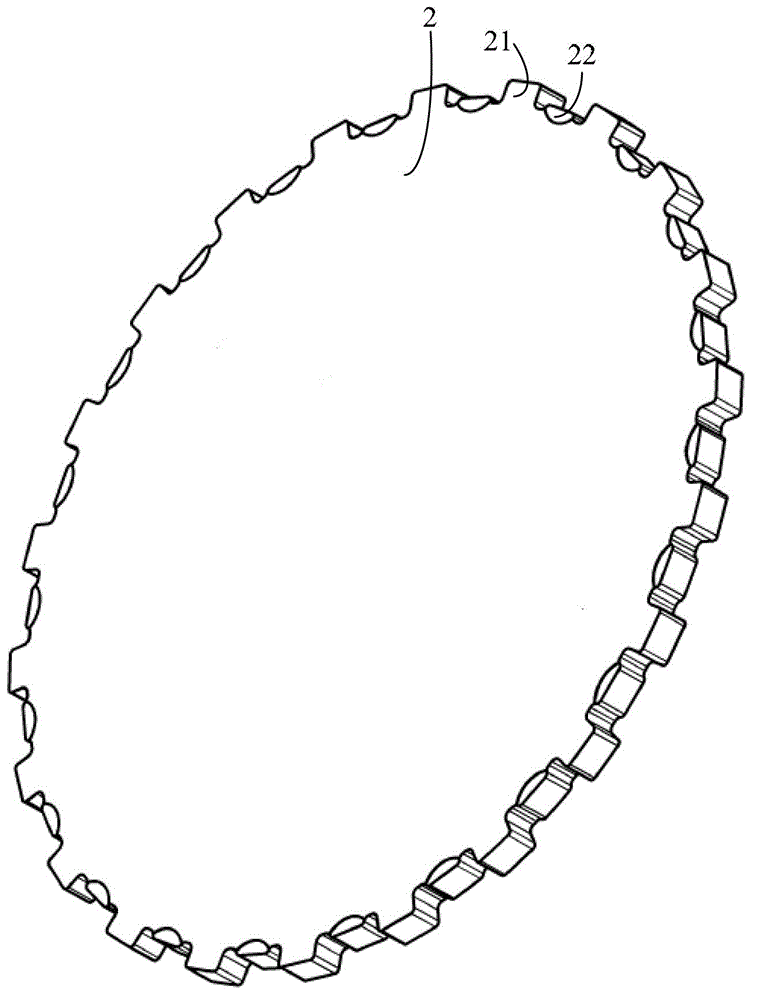

[0022] figure 1 It is a schematic diagram of the box structure of the box assembly provided by the embodiment of the present invention, figure 2 It is a schematic diagram of the box cover structure of the box assembly provided by the embodiment of the present invention, image 3 It is a schematic structural diagram of the box assembly provided by the embodiment of the present invention, Figure 4 for image 3 A partially enlarged schematic diagram.

[0023] An embodiment of the present invention provides a box assembly, which is suitable for any occasion where a box assembly needs to be installed and the axial size of the box assembly needs to be reduced, preferably for automatic transmissions and the like. The box assembly includes a box body 1 and a box cover 2, wherein: at least two axial grooves 11 are opened in the circumferential direction of the end of the box body 1, and the two axial grooves 11 are opened through the The through hole 12 in the thickness direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com