Temperature-raising method and system for coke dry quenching furnace

A technology for dry quenching coke oven and coke, which is applied in the field of heating method and system of CDQ coke oven, can solve the problems of many construction projects, frequent temperature fluctuations, and high risk, so as to maximize value, realize recycling and guarantee The effect of quick output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

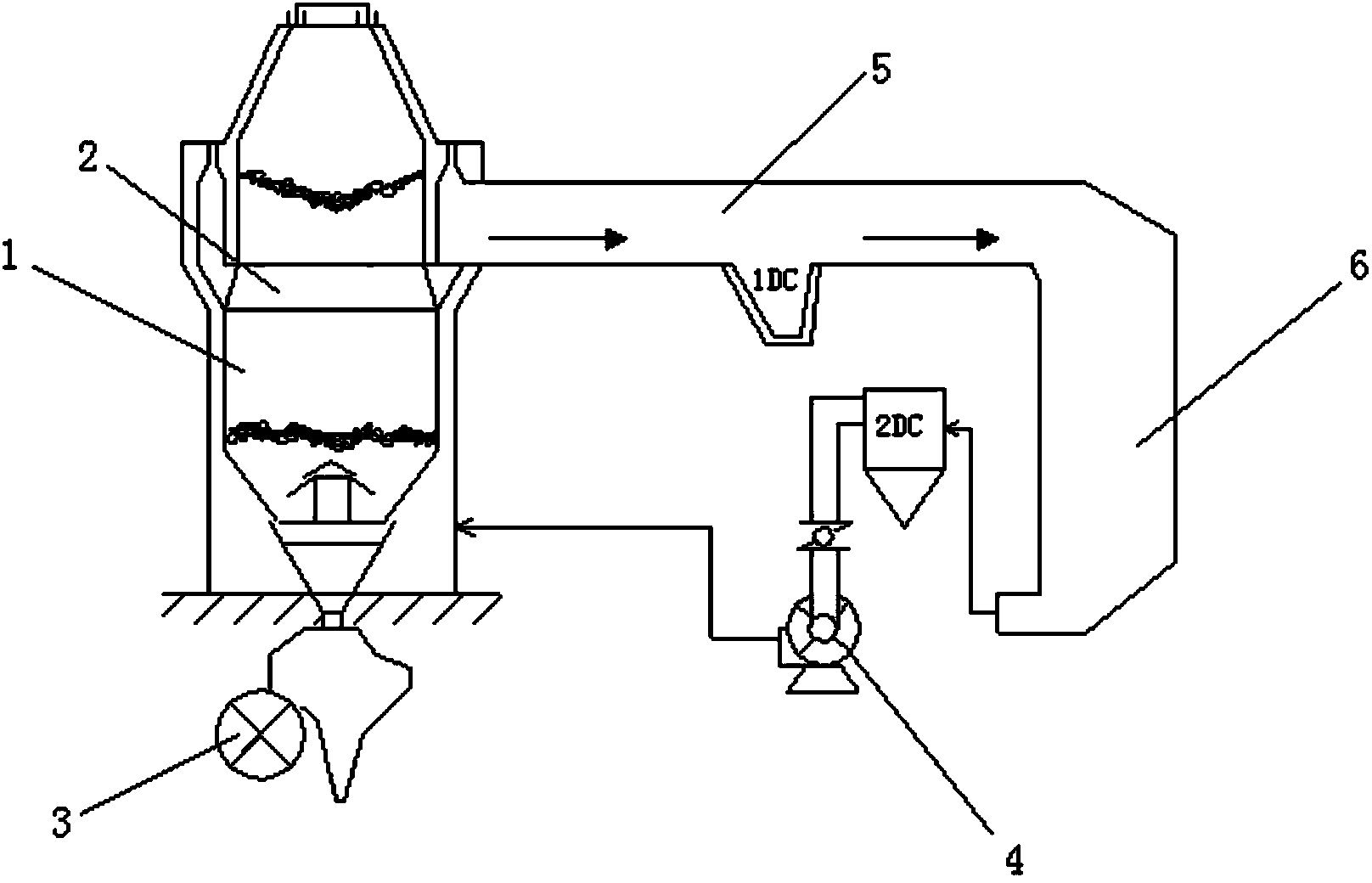

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and working principle of the CDQ coke oven heating method and system according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments Describe in detail.

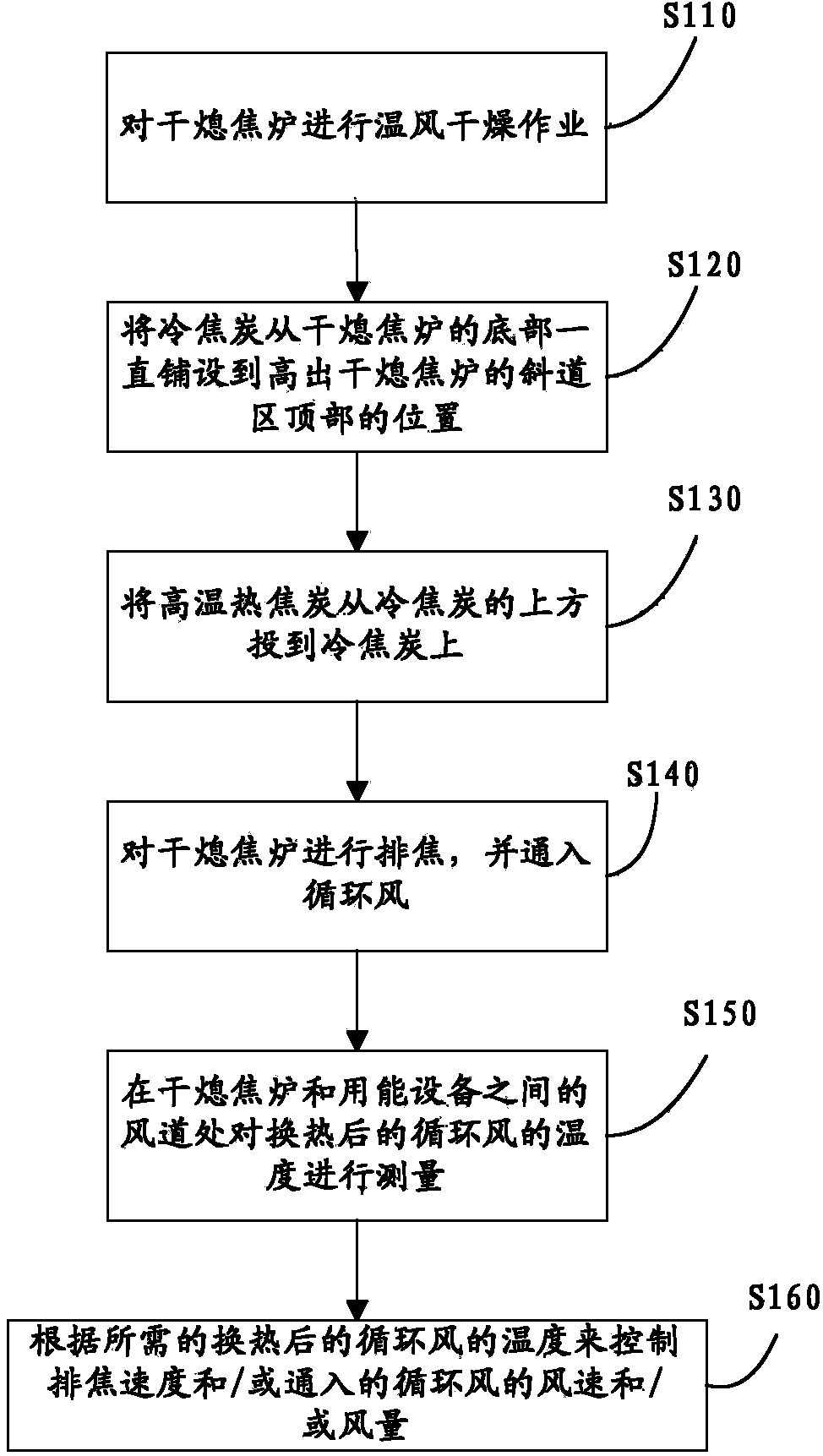

[0024] see figure 1 , the method for raising the temperature of CDQ coke ovens provided by the embodiments of the present invention, comprising:

[0025] Step S110: Carry out warm air drying operation on the CDQ coke oven, so as to remove moisture in the CDQ coke oven and the refractory brick masonry when the primary dust collector is built;

[0026] Step S120: laying cold coke from the bottom of the CDQ oven to a position higher than the top of the chute area of the CDQ oven;

[0027] Step S130: Throwing high-temperature hot coke onto the cold coke from above the cold coke;

[0028] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com