Magnetic force suspension bobbin falling device

A doffing and magnetic technology, which is applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve the problems of complex structure, heavy workload, and warp winding, etc., and achieves convenient assembly, low manufacturing and use costs, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention is further described:

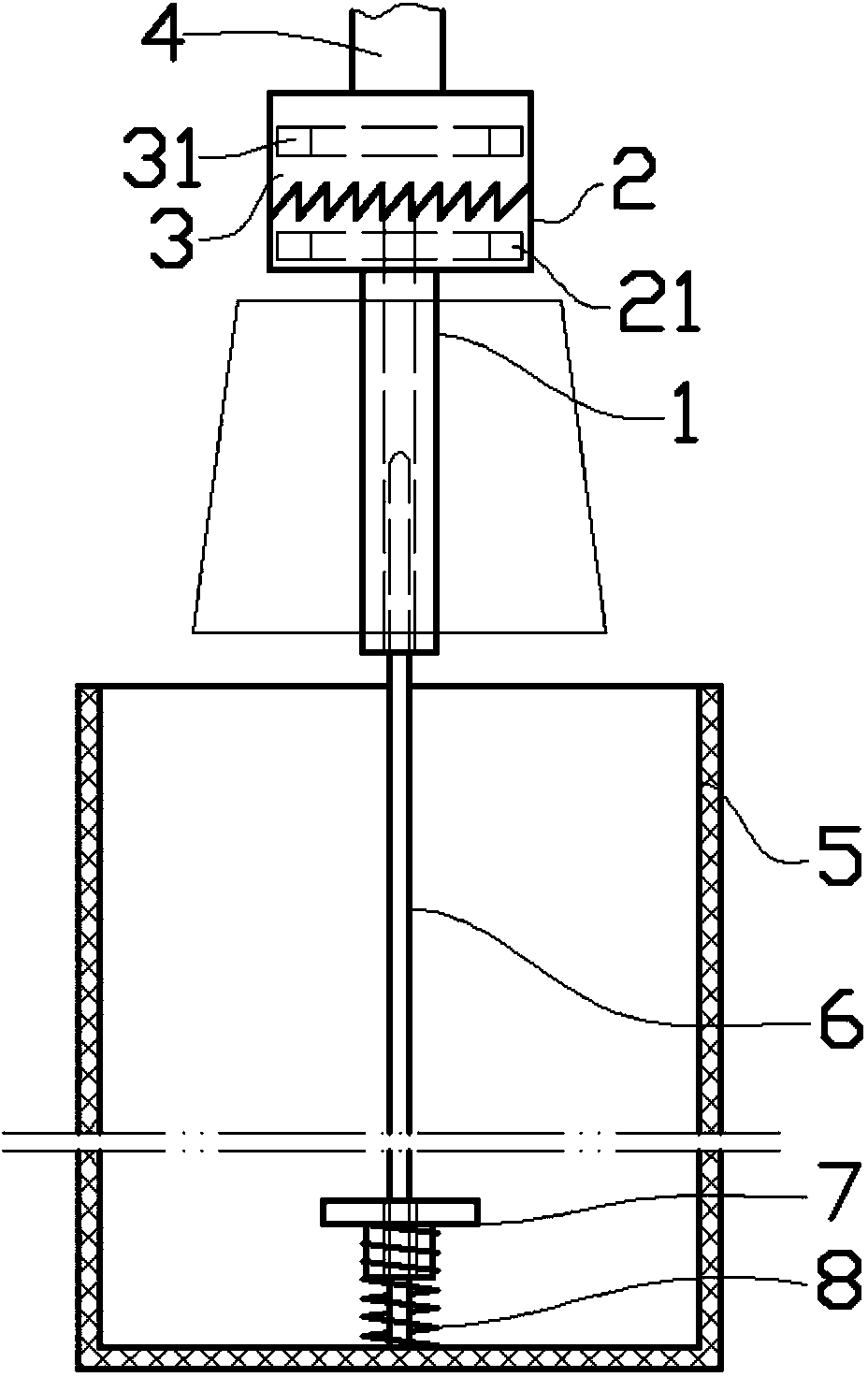

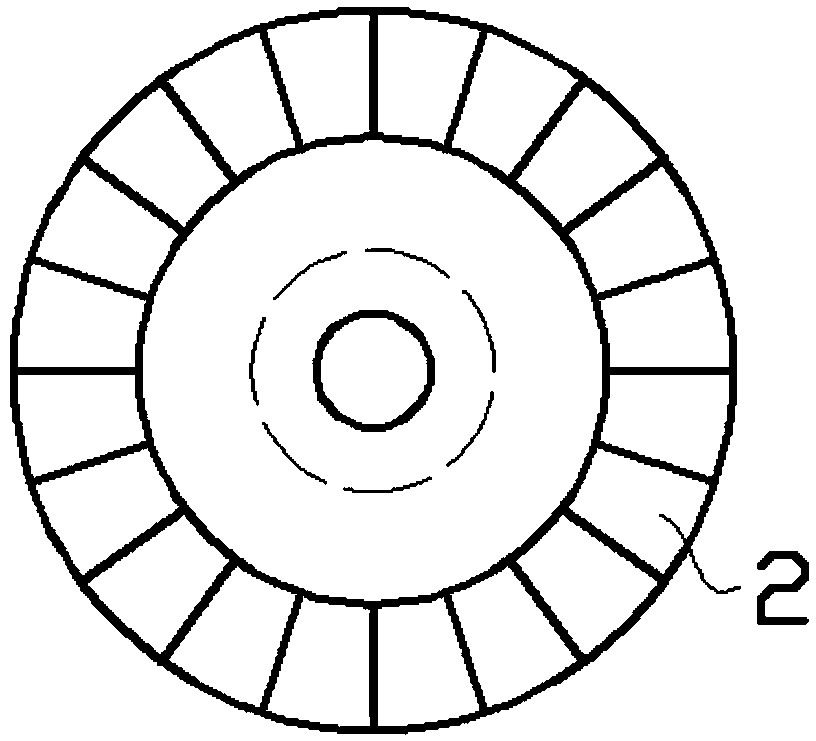

[0011] like figure 1 As shown in the embodiment, the magnetic suspension doffing device includes a yarn bobbin 1, an assembly seat 2, a connecting seat 3, and a rotating shaft 4, and a yarn roll vat 5 is placed on the lower part of the yarn bobbin 1; the connecting seat 3 is A vertical cylindrical shape, which is wrapped with a ring iron block 31, and its lower bottom surface is processed with lower serrations uniformly distributed along the circumference of the axis; the assembly seat 2 is in the shape of a ring, and a ring-shaped magnet is fixed inside it block 21, such as figure 2 As shown, the upper part of the assembly seat 2 is processed with upper serrations uniformly distributed along the circumferential direction of the axis; the magnet block 21 in the assembly seat 2 is magnetically adsorbed on the lower part of the connection seat 3, and the upper serrations are engaged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com