Bar feeding device

A technology of feeding device and ejecting device, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of reducing the processing accuracy of equipment, time-consuming and laborious, and clogging of processing ports, and achieve the effect of ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

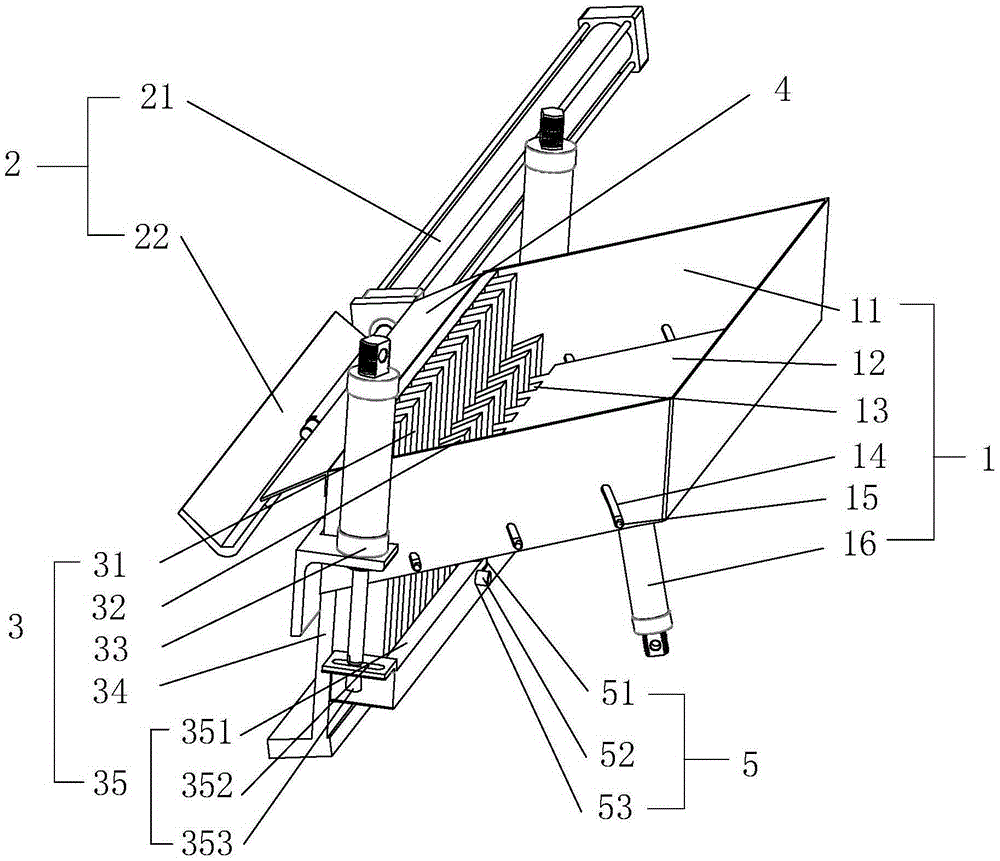

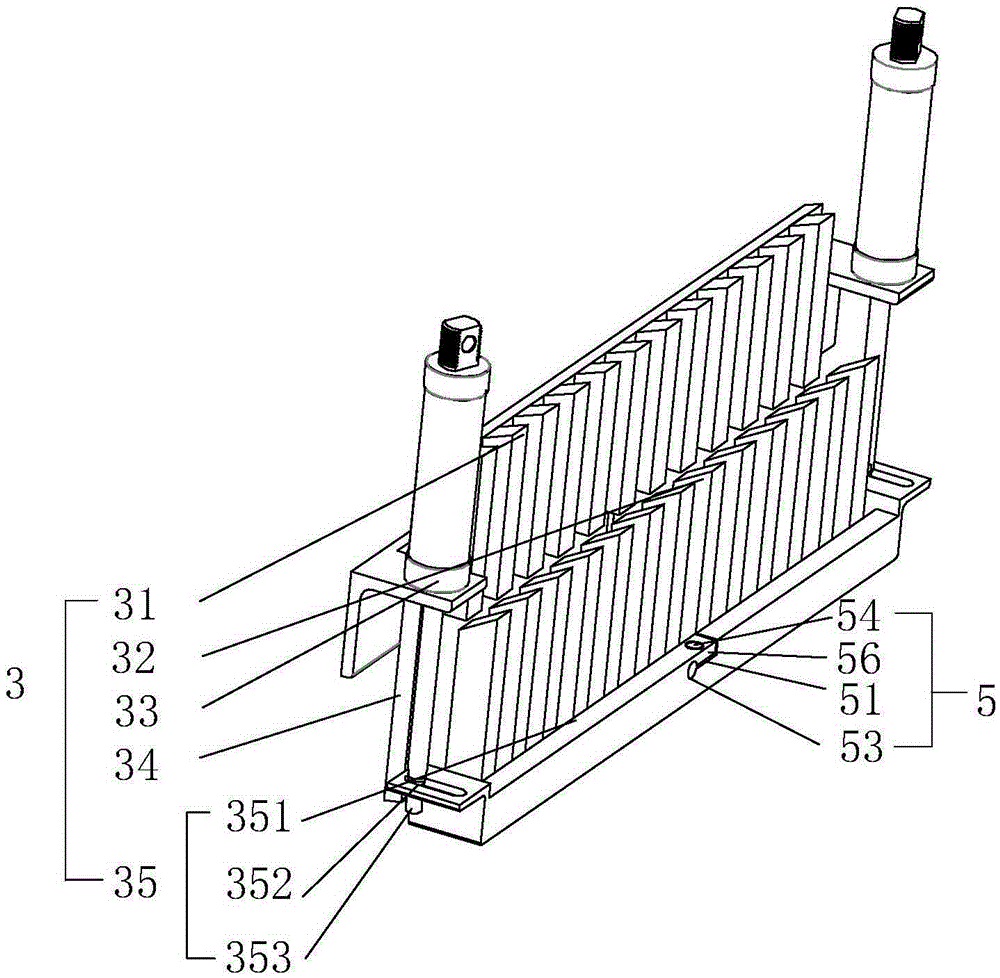

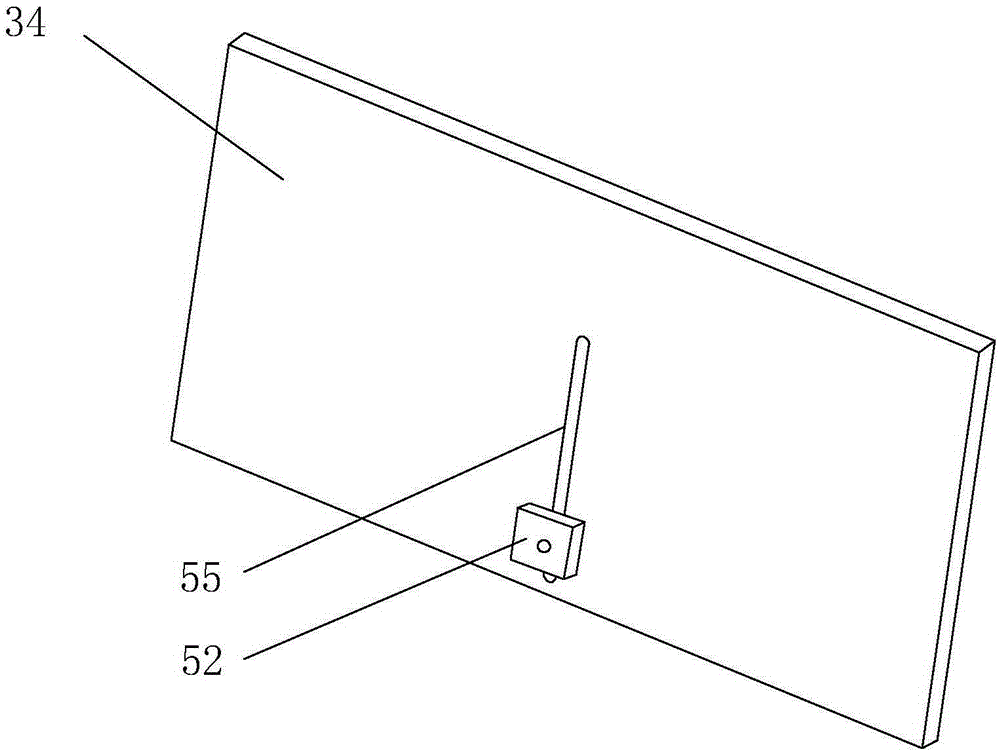

[0032] refer to Figure 1 to Figure 7 The embodiment of the bar feeding device of the present invention will be further described.

[0033]A bar material feeding device, comprising a storage hopper 1, a material pushing device 2, and a material jacking device 3, the storage hopper 1 is arranged on one side of the material jacking device 3, and the material pushing device 2 is arranged on the other side of the material jacking device 3 Side, the pusher device 2 includes a pusher groove 22, a push rod mechanism 21, the pusher mechanism 21 is arranged at one end of the pusher groove 22, and the pusher device 3 includes a pusher main board 34, a pusher column 32. Telescopic device 33. The ejecting column 32 is arranged on the side of the ejecting main board 34 opposite to the storage hopper 1. The top surface of the ejecting column 32 is inclined to the pushing groove 22. The ejecting column 32 and the telescopic device 33 connected, the lifting column 32 slides vertically on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com