Full-automatic air-blowing waste cigarette processing unit

A waste cigarette stick and air-blown technology, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of difficulty in improving manual production efficiency, high labor intensity of workers, and failure to improve the economic benefits of enterprises, so as to reduce labor costs. Strength, increase productivity, effect of processing speed block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail.

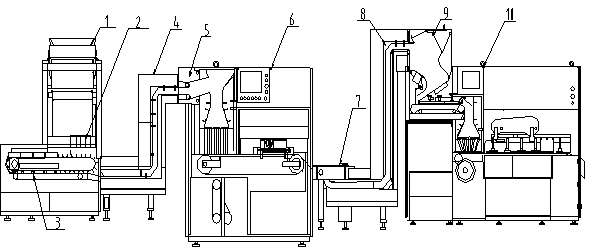

[0028] like figure 1 As shown, the cigarette acceleration mechanism 2 is connected to the tail end of the waste cigarette sorting machine 1, the cigarette sorting mechanism 3 is connected to the cigarette acceleration mechanism 2 and placed perpendicularly thereto, and the first climbing mechanism 4 is connected to the cigarette through a guide plate. On the right side of the sorting mechanism 3, the waste smoke sorting mechanism 6 is connected with the first climbing mechanism 4 through the connecting mechanism 5, the waste smoke turning mechanism 7 is connected with the waste smoke sorting mechanism 6 through the guide slide plate, and the second climbing mechanism 8 passes through The arc-shaped guide plate is connected with the waste cigarette turning mechanism 7 , and the waste cigarette shredded tobacco recovery mechanism 10 is connected with the second climbing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com