Quantity control valve and high-pressure pump with quantity control valve

A technology for controlling valves and high-pressure pumps, which is applied in the field of high-pressure pumps to achieve the effects of reducing mechanical load, reducing rebound speed, and reducing electrical power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

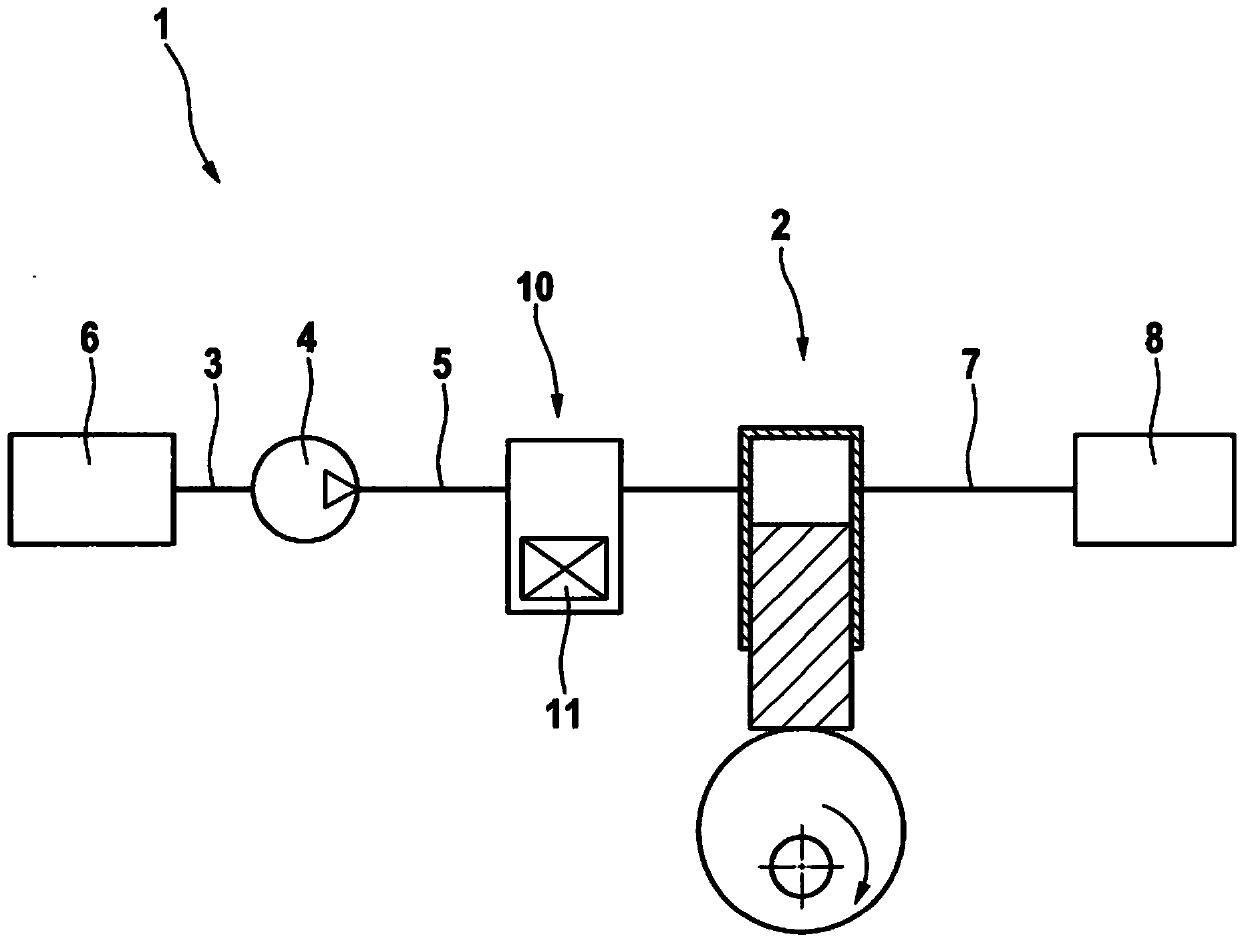

[0026] figure 1 A fuel system 1 of an internal combustion engine is shown in a very simplified illustration. A high-pressure pump 2 , not explained in detail, which is designed as a piston pump, is connected upstream via a suction line 3 , a prefeed pump 4 and a low-pressure line 5 to a fuel tank 6 . Downstream, a high-pressure accumulator 8 (“common rail”) is connected via a high-pressure line 7 to the high-pressure pump 2 . A quantity control valve 10 with electromagnetic actuation (hereinafter referred to as actuator 11 ) is arranged hydraulically between low-pressure line 5 and high-pressure pump 2 and forms an inlet valve for high-pressure pump 2 . Other components, such as the discharge valve of the high-pressure pump 2 figure 1 not shown in It goes without saying that the volume control valve can be integrated into the high-pressure pump 2 .

[0027] When the fuel system 1 is in operation, the prefeed pump 4 conveys fuel from the fuel tank 6 into the low-pressure li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com