A storage battery discharge instrument and its discharge current control method

A discharge current and storage battery technology, which is applied in the field of battery capacity test tools, can solve problems such as increased labor intensity, performance degradation, and increased measurement errors, and achieves improved accuracy and precision, simplified control circuits, and stable discharge current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

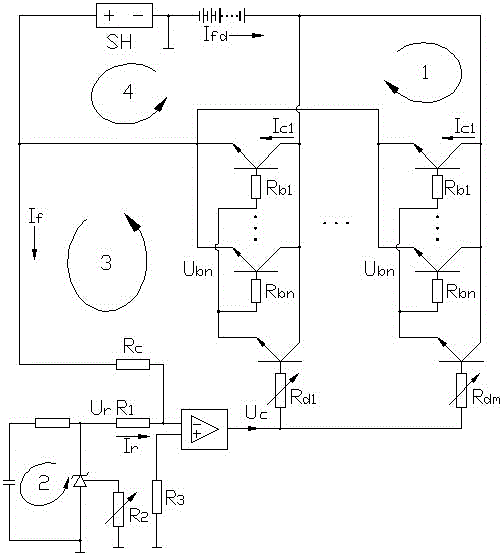

[0028] A battery discharging instrument includes a discharge unit 4 and a set current unit 2 connected to the discharge unit 4, and an automatic adjustment unit 3 is provided between the set current unit 2 and the discharge unit 4. The discharge unit 4 includes 8 sub-discharge units 1 connected in parallel, each sub-discharge unit 1 includes 8 series-connected GTR transistors, and the base of each GTR transistor is connected in series with a resistance R b , The resistor Rb is used to improve the current balance of the emitter; each sub-discharge unit 1 is provided with a preamplifier module and a resistor R connected in series with the preamplifier module d , The preamplifier module can use the simplest amplifier tube or a conventional preamplifier circuit. By selecting the sub-discharge unit and the pre-amplifier tube, or the sub-discharge unit and the pre-amplifier circuit, the amplification factor The total current of each sub-discharge unit tends to be the same, which facili...

Embodiment 2

[0031] The difference between this embodiment and the first embodiment is that the eight parallel sub-discharge units 1 respectively encapsulate a temperature sensor and a heat sink, and are controlled by the same controller. It can effectively improve the heat dissipation efficiency, avoid unnecessary heat dissipation, keep each sub-discharge unit at a relatively constant temperature, ensure the stable performance of each sub-discharge unit, and reduce current deviation.

Embodiment 4

[0033] A method for automatically regulating the discharge current of the battery discharging instrument in the above-mentioned embodiment includes the following steps:

[0034] a) Preset the discharge current by setting the current unit 2 to obtain the set discharge current I r ;

[0035] b) During discharge detection, the automatic adjustment unit 3 obtains the actual discharge current I of the battery through the shunt SH fd ;

[0036] c) The operational amplifier module of the automatic adjustment unit 3 compares the actual discharge current I fd And set discharge current I r the size of:

[0037] When I fd =I r When, the operational amplifier module does not output;

[0038] When I fd > I r When, the operational amplifier module outputs a current-reducing regulated current signal to the pre-amplifier module;

[0039] When I fd r When, the operational amplifier module outputs an adjusted current signal for increasing the current to the pre-amplifier module;

[0040] d) After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com