Tool for detecting location degree of arc surface

A technology for detecting tooling and position degree, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of inability to identify machine tool changes, large center error, and high manufacturing cost of special inspection tools, so as to avoid processing quality accidents, Small error and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

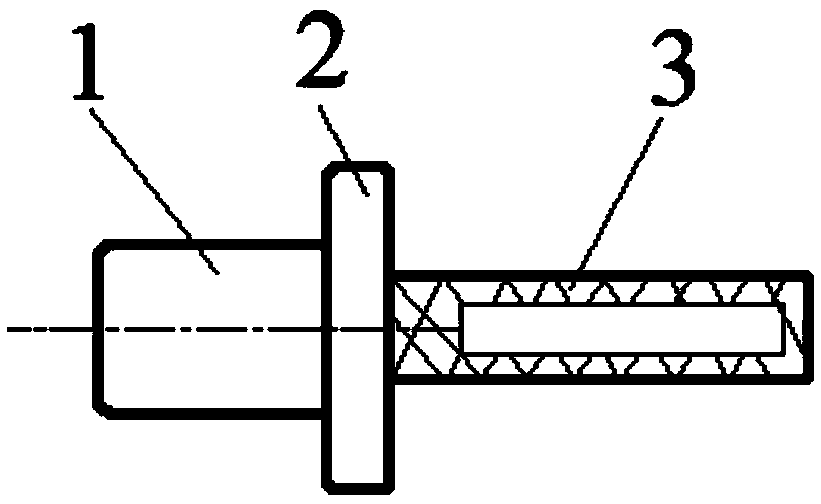

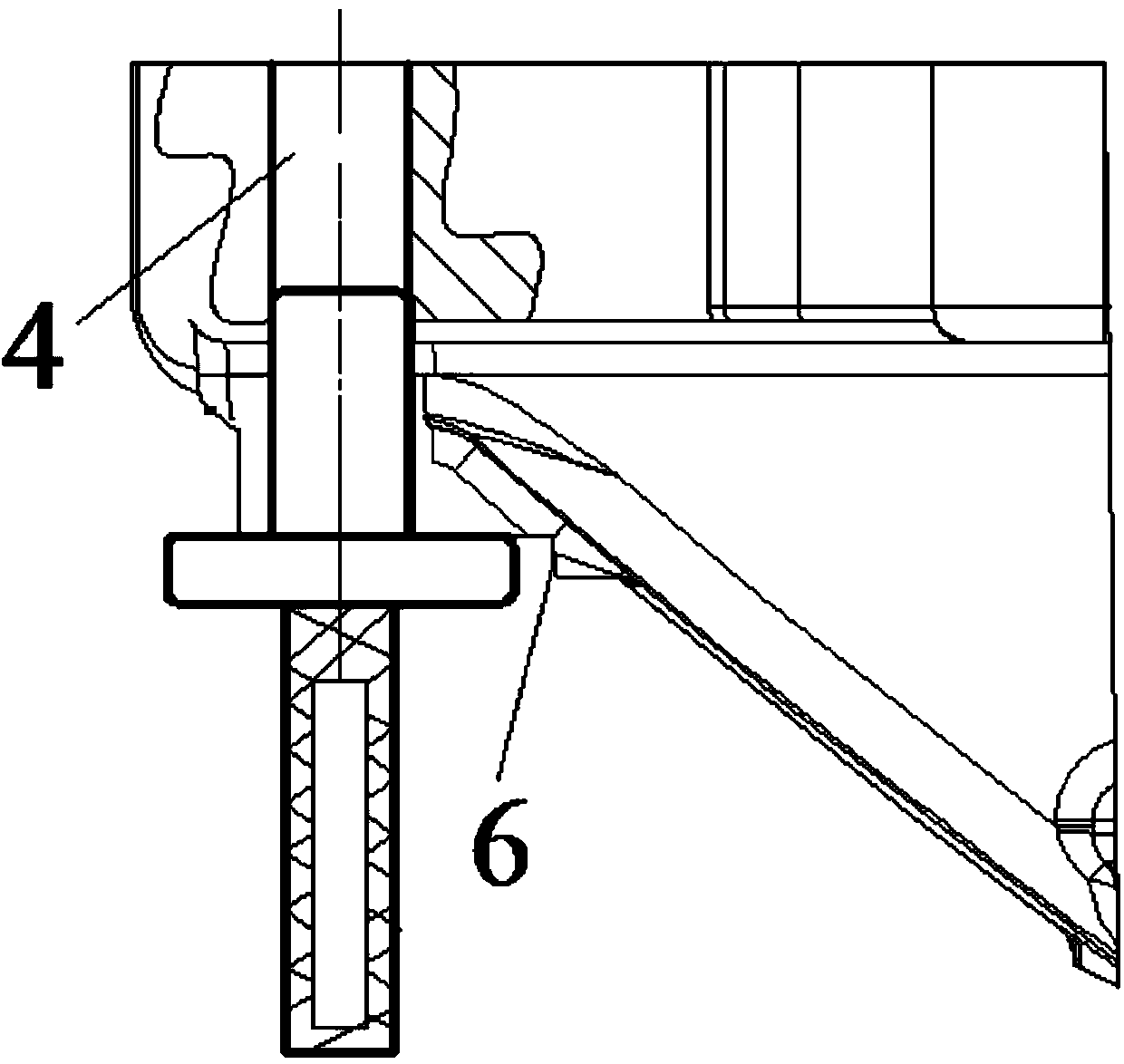

[0019] Such as Figure 1 to Figure 3 As shown, the present invention is a circular surface position detection tool, which is used to detect such as Figure 4 The circular arc surface 6 on the shown engine cylinder block is located at the position where the starter is installed on the rear end surface of the cylinder block. The circular arc surface 6 is also 1 / 10 circle. A mounting hole 4 and a mounting surface 5 are used to install the starter. The mounting hole 4 is used to allow bolts to pass through. The axis of the mounting hole 4 is perpendicular to the mounting surface 5. The arc surface 6 is located on one side of the mounting hole 4 and perpendicular to the mounting surface 5. After the starter is installed on the cylinder block, the bolt is inserted into the installation hole 4 from one end of the installation hole 4, and the other end protrudes from the hole at the installation surface 5, and this end is fastened by a nut, and the nut and the installation surface 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com