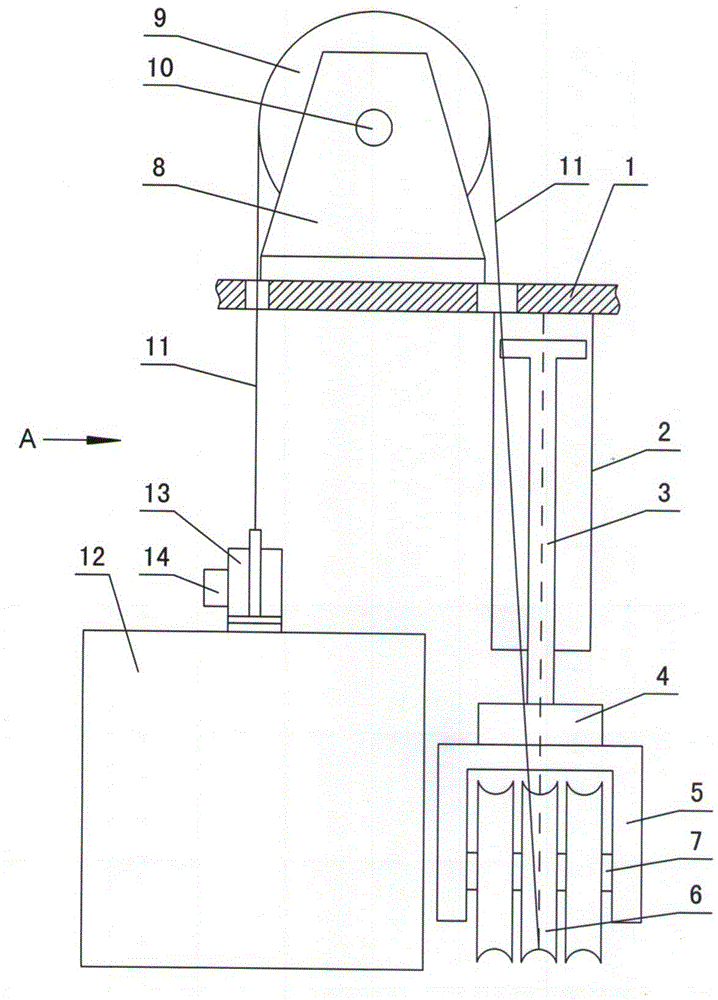

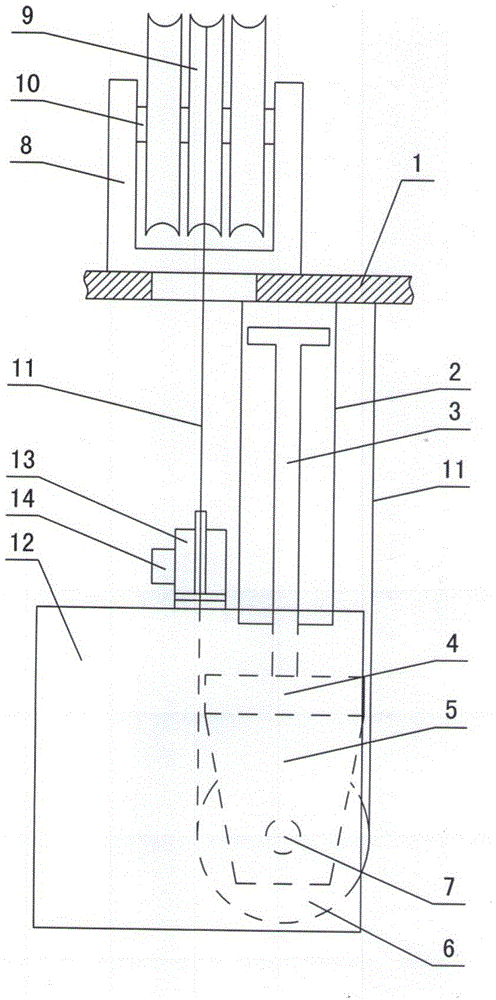

Inverted Side Mounted Hydraulic Freight Elevator

A freight elevator and hydraulic technology, applied in the elevator field, can solve the problems of high running cost and high power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0010] Embodiment: ①. Use the plunger rod of the inverted 2:1 oil cylinder plus the weight of the pulley group to bear the force of the car, such as: the stroke is 12m, the weight of the ?110×6500mm plunger rod is 500kg + the weight of the lower pulley group is 150kg, The weight of the car is 1000kg. When the plunger rod and the pulley block move downward, the 325kg weight of the upward movement of the car can be offset, that is, the hydraulic cylinder only needs to exert a force of 675kg to make the car move upward.

[0011] Suppose the travel of the car is 12m, the total weight of the car and the goods carried is 2.5t, and the lifting times of the car are 50 times per day.

[0012] When using an electric hoist, 12m×2.5t=300KN, 300KN×100 times=30000KN, 30000KN÷3600s=8.333 kWh;

[0013] When a hydraulic elevator with a hydraulic cylinder installed on the ground is used, the car goes down without being driven by a motor, 0.65t (weight of the plunger rod + weight of the lower pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com