A coated wire catalyst or carrier and its manufacturing method

A technology for coating wires and manufacturing methods, applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of uneven loading, low catalyst strength, and small external void ratio, etc. Excessive pressure drop, effect of increasing external surface area and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

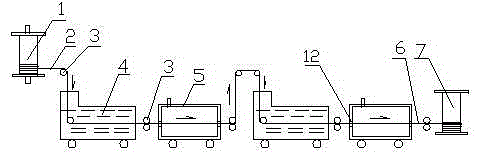

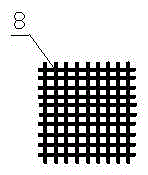

[0031] 1. Slurry production: powder the catalyst (or carrier) material to be coated (the catalyst material includes platinum, palladium, rhodium, cobalt, molybdenum, nickel, etc., and the carrier material includes all known The carrier material, such as activated alumina, magnesia, zirconia, silicon carbide, silicon oxide, titanium oxide, etc.) is mixed with specific organic matter and water, and made homogeneous by stirring to prepare a slurry. In order to make the coated catalyst (or carrier) slurry have a certain degree of ductility and elasticity after drying, some special organic substances must be added to the slurry, such as water-based polyurethane, etc. What kind of organic substances should be added to ensure elasticity and ductility , It must be determined according to the nature of the carrier or catalyst material. If the catalyst (or carrier) material is alkaline, anionic polyurethane must be added. In short, increasing the elasticity and ductility of the film aft...

Embodiment B

[0041] 1. One or more layers of cloth-shaped catalysts or carriers of a certain width made by the method of Embodiment A are rolled into a cylindrical shape (that is, a cylinder) to make a roll-type catalyst of a certain diameter (according to product requirements) or catalyst carrier;

[0042] 2. Put the roll-type catalyst or carrier in a water bath to bond the cloth of the roll together, and then dry it;

[0043] 3. Roasting the reel to finally make a reel-type catalyst or carrier;

[0044] 4. The roll-type catalyst or carrier can be used for exhaust gas purification of automobiles.

Embodiment C

[0046] 1. Slurry production: use activated alumina and magnesium carbonate or magnesium nitrate as raw materials, and finally synthesize magnesium aluminum

[0047] Mix raw materials according to the ratio of spinel, add certain amount of water and other organic raw materials to make slurry for coating; or use activated alumina, white carbon black, light-burned magnesia as raw materials, according to the chemical composition of cordierite Mix raw materials to make slurry; or use activated alumina as the main ingredient and add some other auxiliary materials to make slurry;

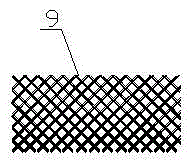

[0048] 2. Coating: According to the method in Embodiment A, first erect carbon fiber threads (or other organic fiber threads) of 1k, 3k, 6k, 12k or other specifications, and then coat the carbon fiber threads, but this coating It is disposable, because the thickness of the coated slurry only needs to be 0.1-0.3 mm, and the coated wire cannot be twisted, so that the dried coating will not have slight cracks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com