End wall molded line modeling method for intermediate case of gas compressor

A compressor and intermediary technology, applied in image data processing, special data processing applications, instruments, etc., can solve problems such as unsatisfactory fitting effect of geometric line concave and convex curvature transition areas, limited scope of application, complicated implementation methods, etc. , to achieve the effect of good aerodynamic design index and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following, combined with the example of the intermediary casing of the compact compressor and the CFD calculation results, the detailed description is as follows: image 3 The specific implementation process of the present invention shown.

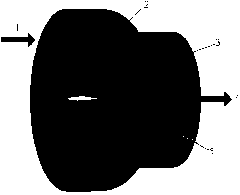

[0055] Step 1: Construct the end wall profile according to the geometric design parameters of the compressor intermediary casing, that is, to construct the 3D model of the compressor intermediary casing according to the known design parameters ( figure 1 ) for two-dimensional simplification ( figure 2 ), and perform dimensionless processing on the axial and radial coordinates of each point.

[0056] Among them, the geometric design parameters include: the Z-direction dimensionless coordinate Z of the entry point of the casing 6 , R to the dimensionless coordinate R 6 And the geometric angle of the casing inlet, the Z-direction dimensionless coordinate Z of the casing exit point 8 , R to the dimensionless coordinate R 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com