Corner supporting thin-wall shell structure

A thin-walled shell and corner support technology, applied in the direction of supporting machines, engine frames, mechanical equipment, etc., can solve the problems of structural instability, shell structure deformation, lack of aesthetics, etc., to improve space utilization, reliable mechanics Structure, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

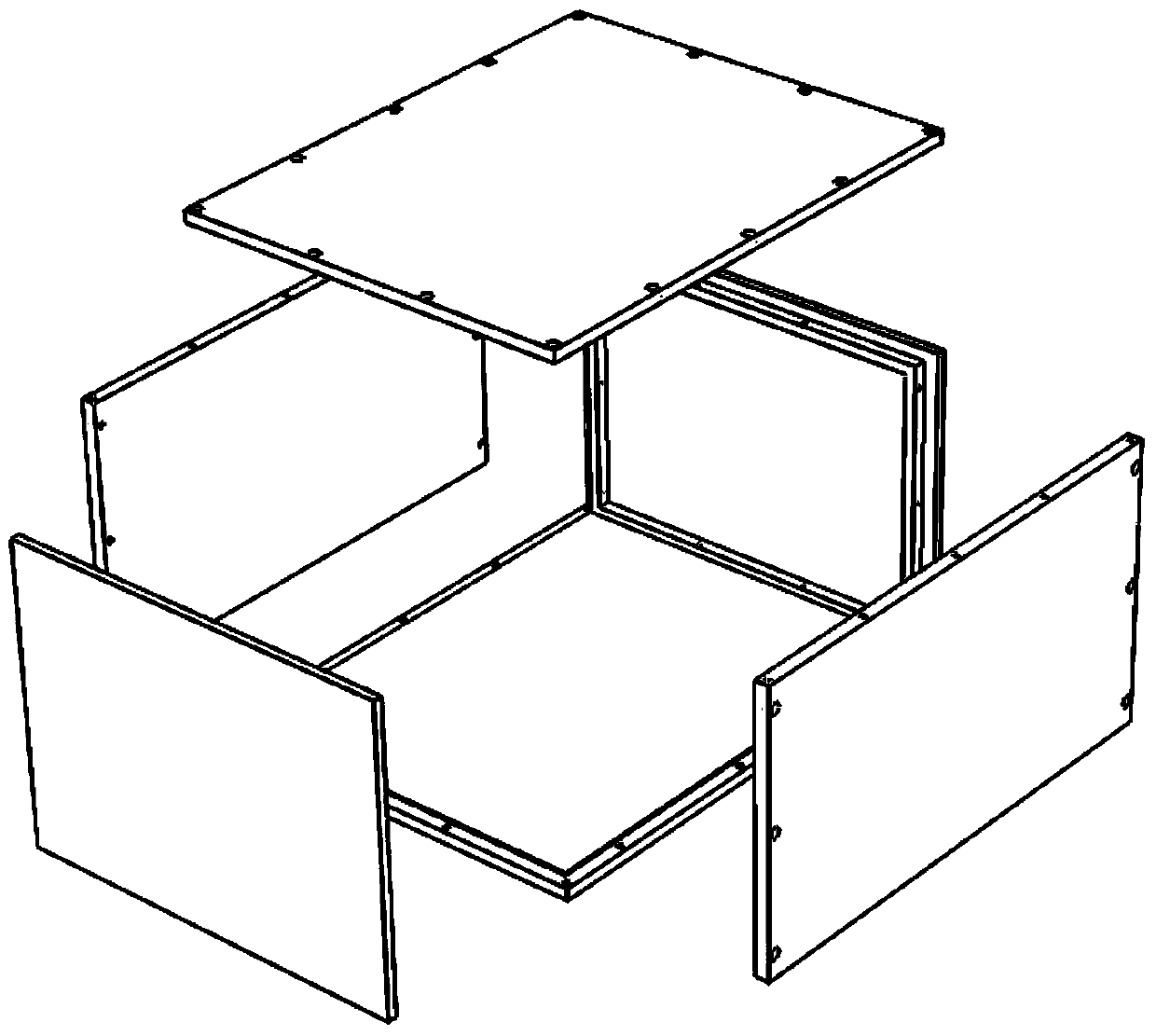

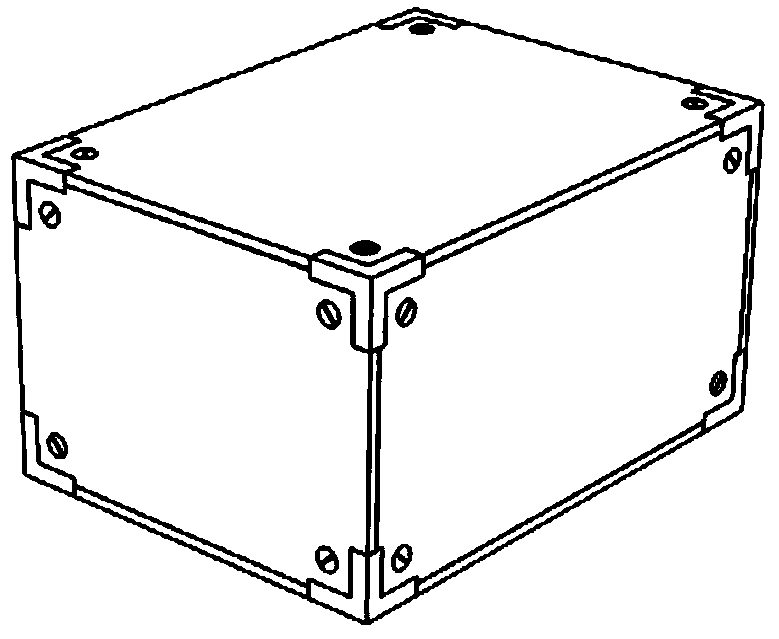

[0021] The angle support thin-wall shell structure of the present invention, its preferred embodiment is:

[0022] It includes a shell, the shell is mainly composed of a plurality of panels, the top corners of three adjacent panels are connected by a corner support structure, and the corner support structure has three panel mating surfaces, and the three panels are respectively connected with After the mating surfaces of the three panels are mated, they are fixed by mechanical connectors.

[0023] The panel mating surface is the outer contour surface or the inner contour surface of the corner support structure.

[0024] The panel and the matching surface of the panel are positioned by pins and fastened by threads.

[0025] The outer contour surface is flush with the panel.

[0026] The panel and the panel mating surface are positioned and screwed together by the mating surface.

[0027] The outer contour surface is provided with a step structure matched with the panel.

[...

specific Embodiment 1

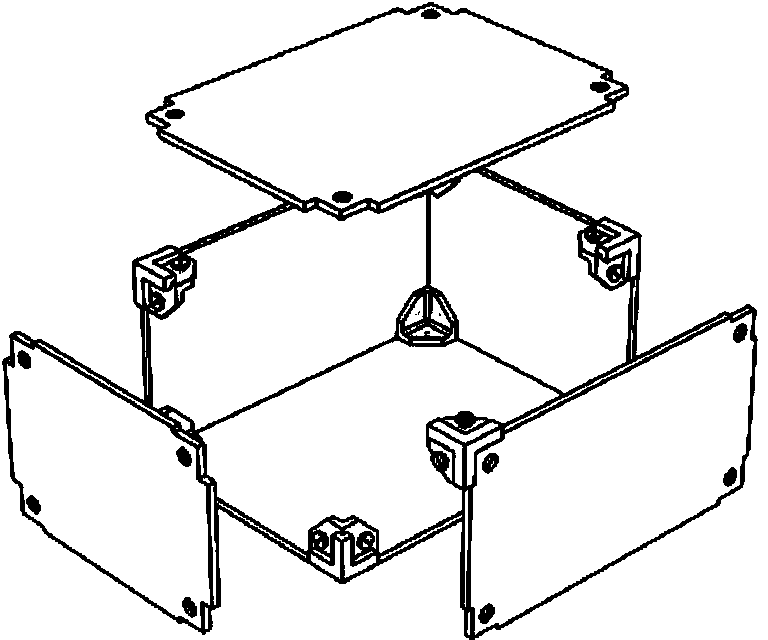

[0030] Such as Figure 3a , Figure 3b , Figure 3c As shown, the corner support components include: 1 corner support and 3 bolts.

[0031] Corner Support - The exterior has three mutually perpendicular mounting surfaces for the installation of three adjacent panels. The contact area of the installation surface is relatively large, and the mutual vertical precision between the panels can be effectively guaranteed. The three edges of the corner support protrude from each installation plane, and its outline matches with the shell panel, which can effectively locate the position of each panel. The three edges and sharp corners can be designed with rounded corners, chamfered corners and bevels of various sizes according to the shape of the whole machine.

[0032] Bolts - Install after housing panels are installed. The screw thread is connected with the corner support, and the round platform is centered with the round hole of the panel, so that the corner support components ...

specific Embodiment 2

[0035] Such as Figure 5 As shown, the angular support structure is designed as an obtuse angle. In practical applications, the angular support structure can be designed in the form of multiple angles as required, thereby forming shells of various shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com