Improved ore discharging device of grid type ball mill

A ball mill, an improved technology, applied in the direction of grain processing, etc., can solve the problems of center disc falling off, affecting production, equipment failure, etc., and achieves the effects of low wear rate, long service life and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

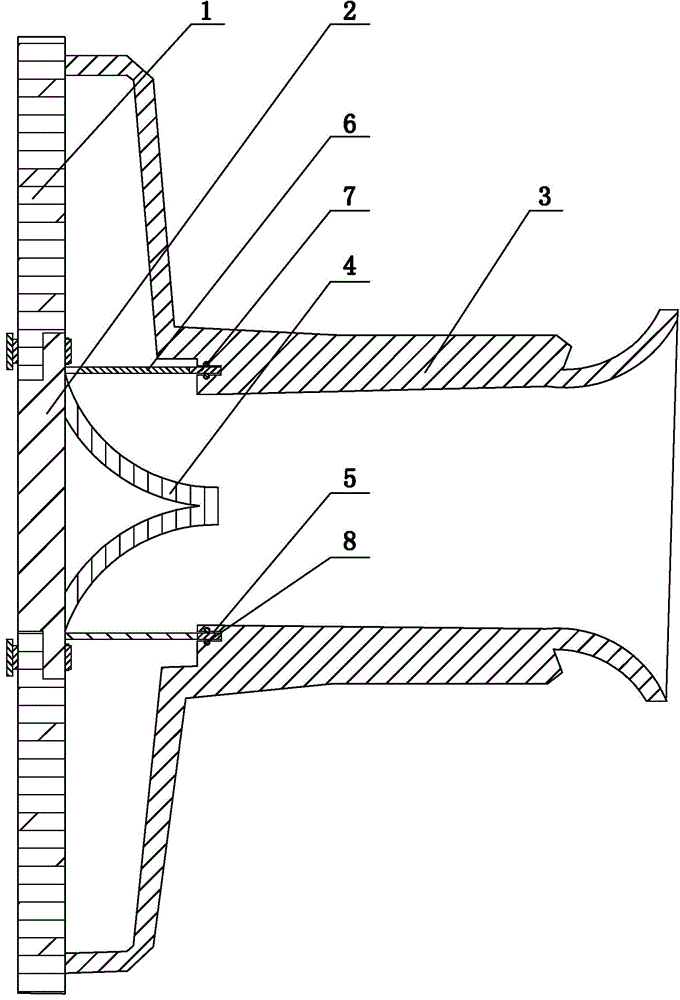

[0014] like figure 1 As shown, the center liner of the grid-type ball mill in the present invention includes a grid plate 1 and a center liner 2. The grid plate 1 is pressed on the end cover of the ball mill, and a hollow journal 3 is arranged on the end cover. A hollow trumpet-shaped material guide column 4 is provided at the position, a groove 5 is provided on the end surface of the journal 3 close to the end of the grid plate 1, and a connecting rod 6 is vertically arranged on the central liner 2, and the connecting rod 6 is connected to the ring-shaped fixing piece 7, and the ring-shaped The fixed piece 7 is embedded inside the groove 5, the ball 8 is arranged between the outer periphery of the annular fixed piece 7 and the upper surface of the groove 5, the ball 8 is arranged between the inner periphery of the annular fixed piece 7 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com