A Visual Ultrasonic Detection Method for Partial Discharge Fault Detection

A partial discharge and fault detection technology, applied in radio wave measurement systems, measurement devices, testing dielectric strength and other directions, can solve problems such as manual search for the location of sound sources, errors in positioning results, and detection results that are not presented to users in a visual way. Achieve the effect of realizing ultrasonic positioning, high-precision ultrasonic positioning, and visual detection and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

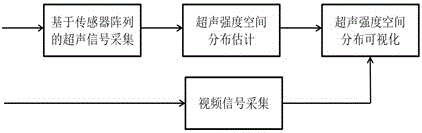

[0026] as attached figure 1 As shown, this embodiment involves three main parts: signal acquisition, signal processing, and result visualization, namely: firstly, the ultrasonic sensor array is used to collect the ultrasonic signals that appear in the power equipment, and the spatial distribution of ultrasonic intensity is estimated; at the same time The video signal of the scene is collected, and then based on the acquired ultrasonic signal and video signal, the spatial distribution of ultrasonic intensity is visualized, so as to intuitively display the spatial position of the partial discharge point as the ultrasonic source.

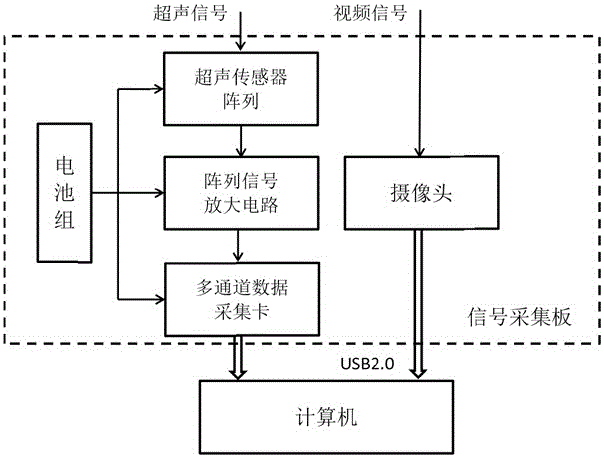

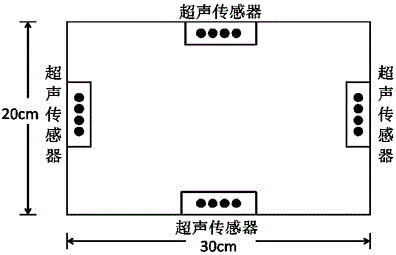

[0027] as attached figure 2 As shown, the collection of the above-mentioned ultrasonic signal and video signal in the present embodiment adopts an ultrasonic and video centralized acquisition board to collect; the ultrasonic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com