Nano-film spinning device

A spinning device and nano-film technology, applied in the field of nano-film spinning devices, can solve problems such as difficulty in mass production, low nanofiber yield, needle blockage, etc., and achieve the effect of realizing industrialized production and meeting the needs of production and life.

Active Publication Date: 2014-08-06

江苏瀚霆环保滤材有限公司

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The morphology of the prepared fiber is greatly affected by the solution concentration, viscosity and other properties; the needle diameter is small, which is easy to cause needle clogging, which greatly limits the preparation of fibers coated with nanoparticles; the average fineness of the prepared fibers is still hundreds of nanometers

At the same time, the yield of nanofibers prepared by electrostatic needle spinning is very low, and it is difficult to achieve industrialized mass production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

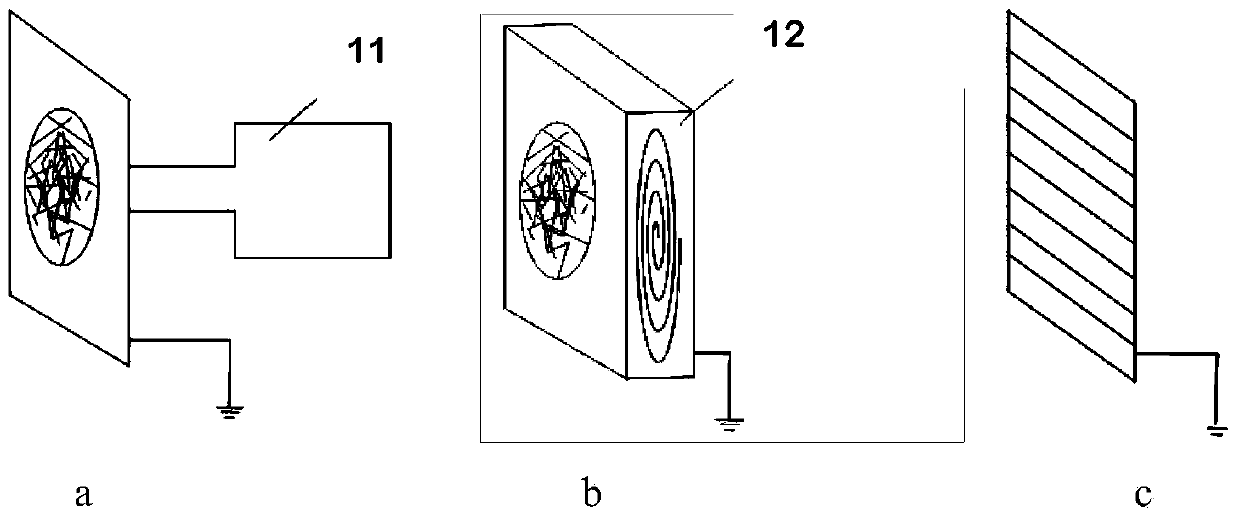

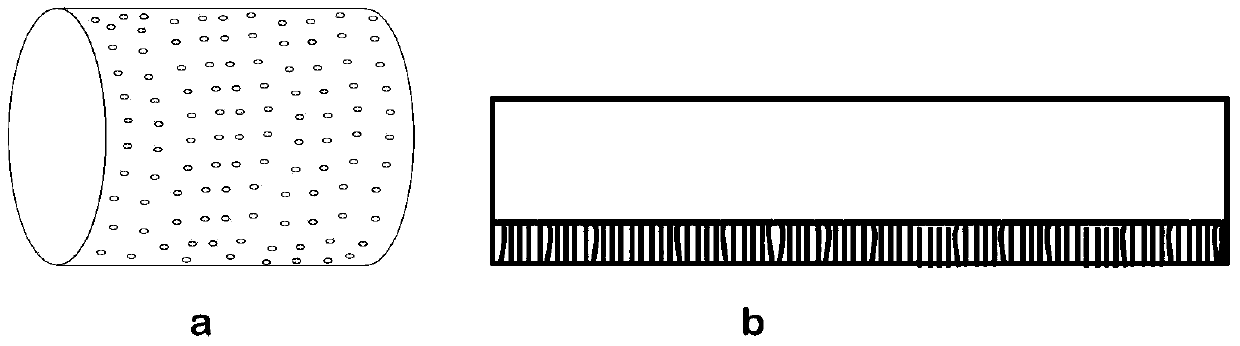

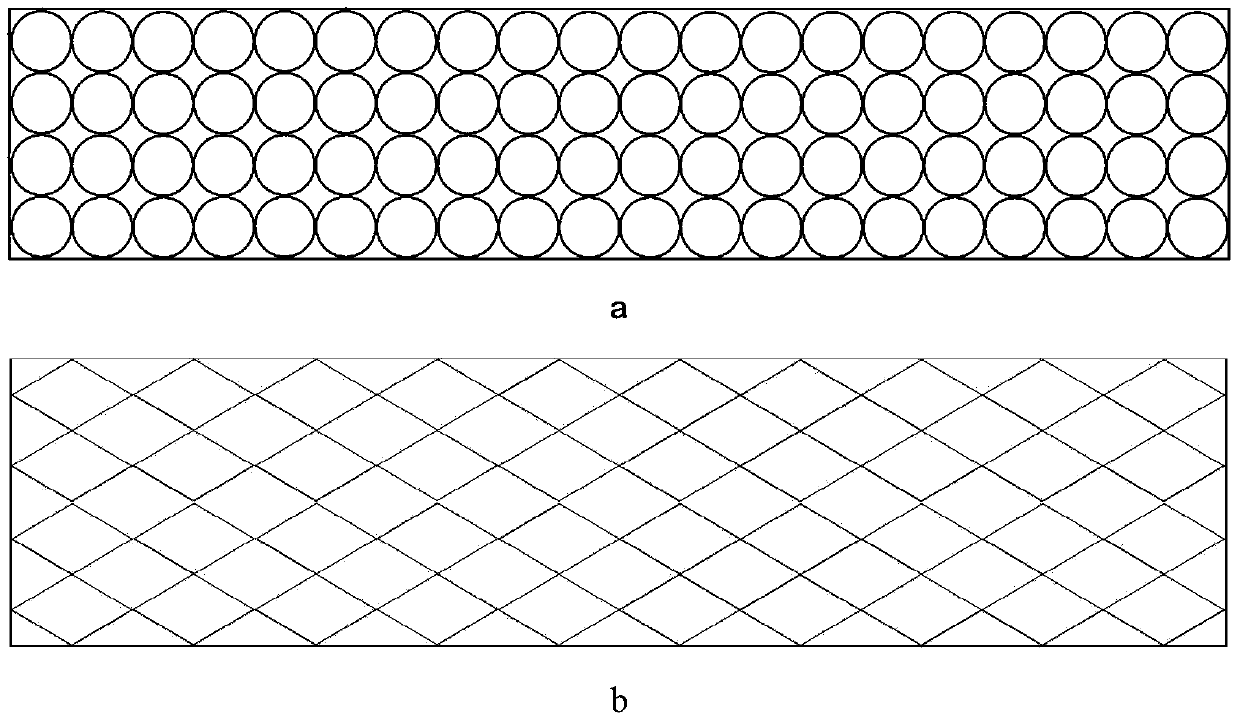

The invention discloses a nano-film spinning device. The nano-film spinning device comprises a film generator connected with a high-voltage electrostatic generator and a receiving pole plate arranged at the front end of the film generator. An airflow cavity is formed in the rear end of the film generator. A film forming device is arranged on an outlet of the airflow cavity. A gas inlet and a nano-particle inlet are formed in an inlet of the airflow cavity. The gas inlet is connected with an airflow generator. The nano-particle inlet is connected with a nano-particle container. Compared with the prior art, a nano-film is stretched in a high-voltage electrostatic field or an airflow field or a mixed field of the high-voltage electrostatic field and the airflow field, and therefore the diameter of prepared nano-fibers is smaller. Meanwhile, nano-particles are added to the airflow cavity through the nano-particle container, the nano-film and the nano-particles are more uniformly mixed in the spinning process, and uniform protrusion structures on the surfaces of the fibers can be effectively prepared. The appearance and the shape of the fibers can be accurately controlled by controlling the shape, the property and the like of the particles.

Description

technical field [0001] The invention relates to a nano film spinning device, which belongs to the technical field of spinning preparation. Background technique [0002] Nanofibers have the characteristics of ultra-high specific surface area, extremely large aspect ratio, high surface activity, superior mechanical properties (high strength and high toughness), etc., and are widely used in textile engineering, environmental engineering, biotechnology, medical and health care, energy storage, military It has very broad application prospects in different fields such as anti-terrorism security. The most direct and basic method for traditionally preparing ultrafine fibers and nanofibers is electrospinning. At present, the preparation of nanofibers in laboratories and industries widely adopts single-nozzle or multi-nozzle syringe electrospinning nanofiber devices. [0003] There are some drawbacks in traditional nano-electrospinning technology. The morphology of the prepared fib...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01D5/00

Inventor 何吉欢陈柔羲

Owner 江苏瀚霆环保滤材有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com