Integrated Design Method of Waverider Precursor and Inlet with Controllable Transverse Pressure Gradient

A technology of lateral pressure and wave-riding precursors, which is applied to the combustion of the intake port of the power plant, aircraft parts, ground devices, etc., to achieve the effect of high lift resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

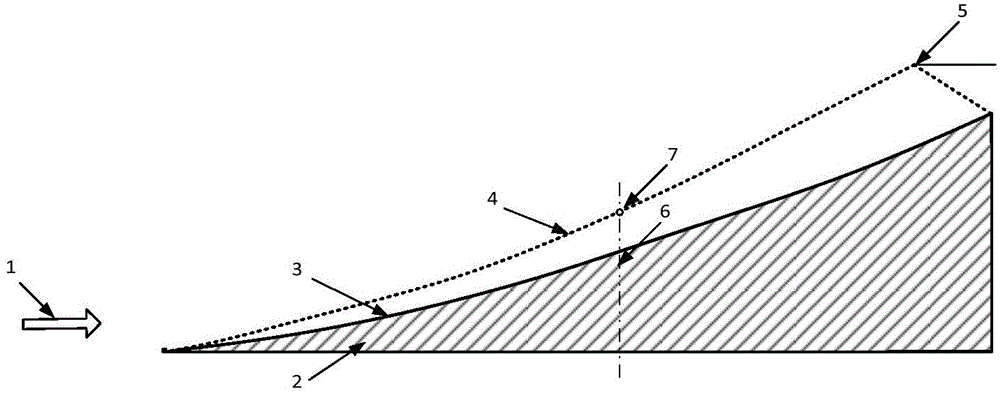

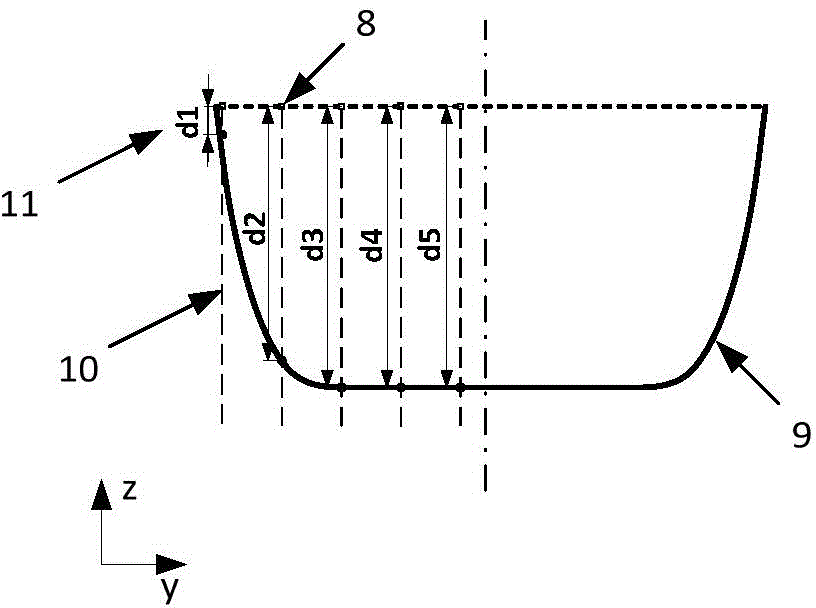

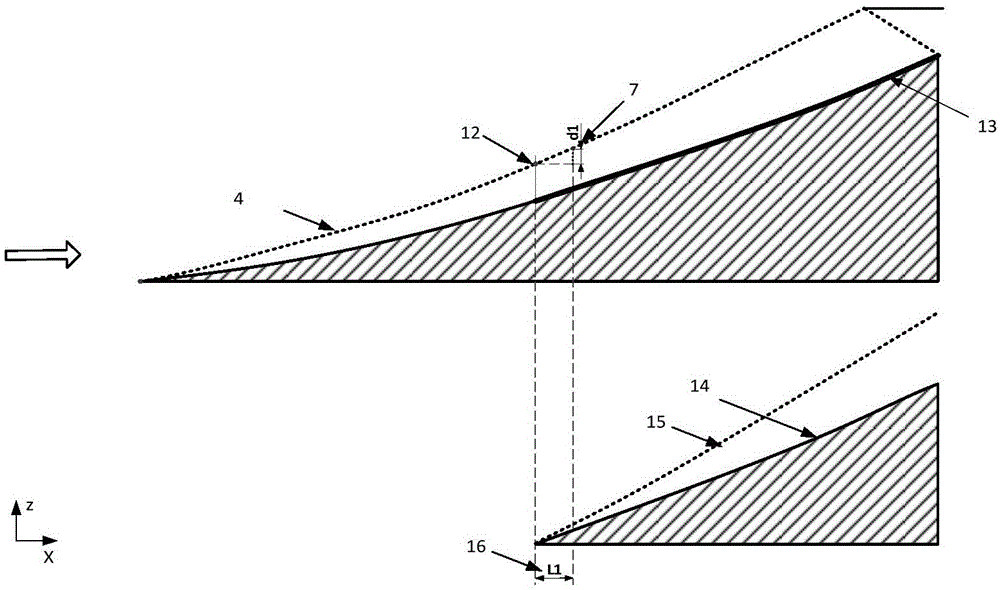

[0037] Example: Considering the change of lateral pressure, the integrated design method of the waverider body and the inlet port. In this example, the incoming flow Mach number Ma=5.5 is given, and the basic flow field is designed as follows: figure 1As shown, according to the design method of the present invention, it can be designed as Figure 6 All-in-one unit shown. The device is composed of an external compression part 19 of the binary air inlet, an internal compression part 21 of the binary air inlet and an external compression part 20 of the waverider precursor. Under design conditions, the pressure gradient on both sides of the shock wave is slightly larger than that of the binary inlet in the middle, and the theoretical capture flow rate is greater than 100%. The device has a binary inlet transverse overflow port 24, and the transverse overflow port is designed according to the reflected shock wave angle.

[0038] Using the generation device of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com