Composite material structure of scaffold

A composite material and scaffolding technology, applied in the direction of building structure support, building structure support, scaffolding connection, etc., can solve the problems of inconvenient assembly and transportation, increased overall quality, safety concerns, etc., and achieve the goal of increasing convenience and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

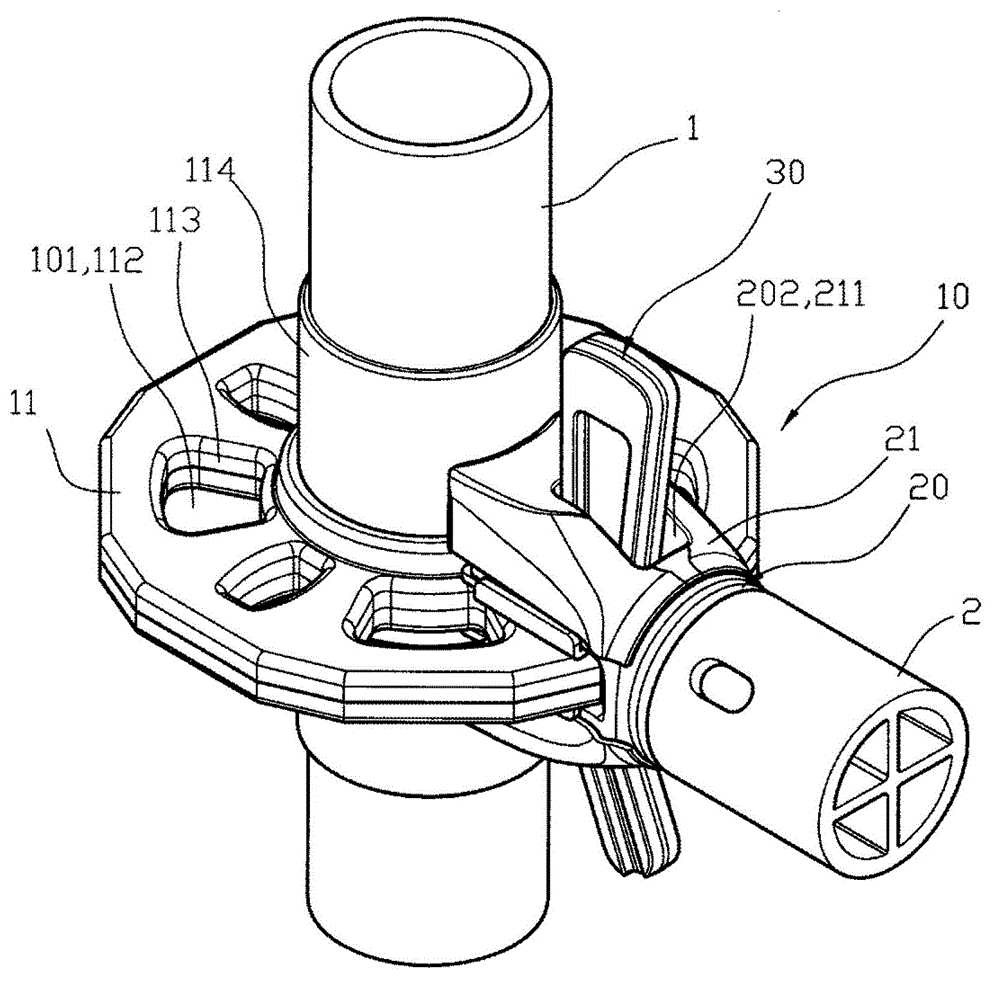

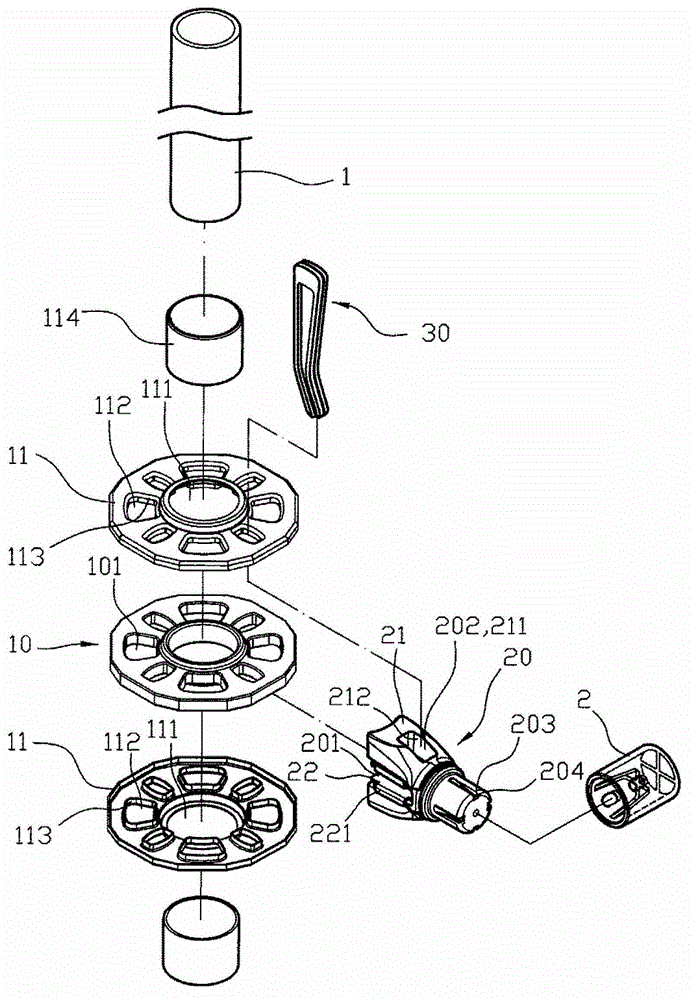

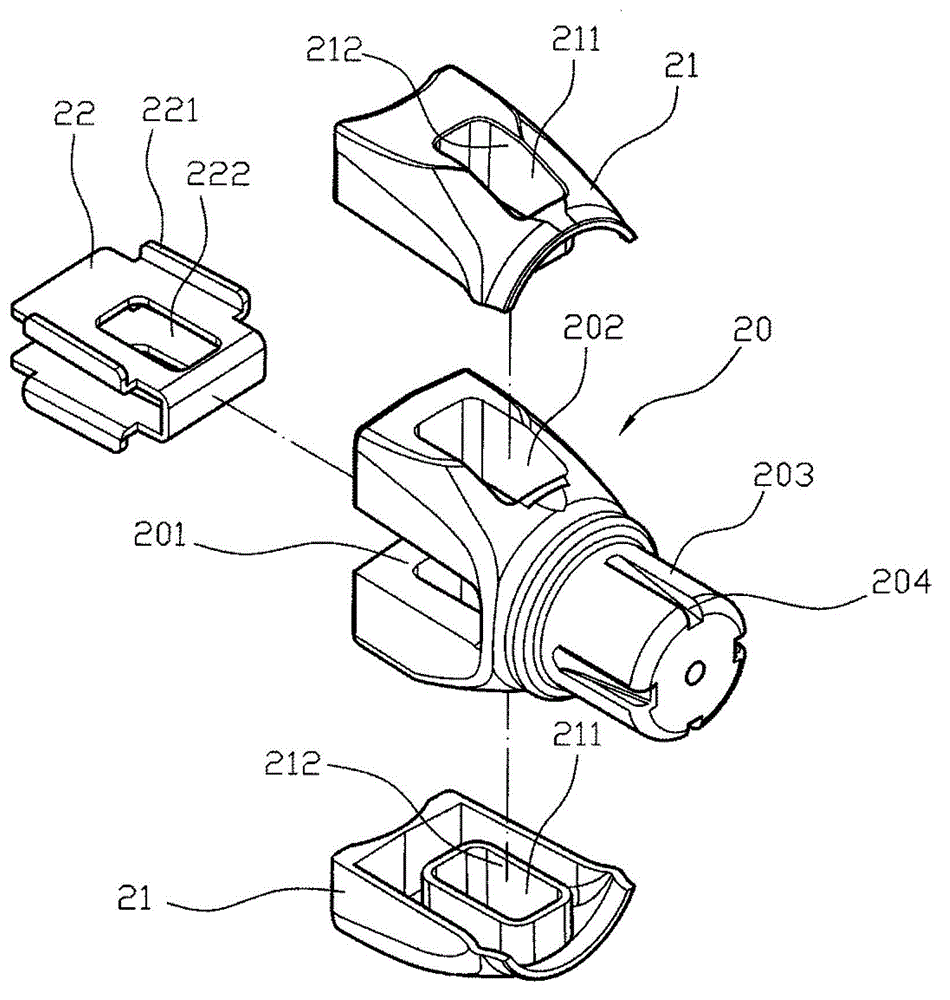

[0018] First, please see figure 1 , figure 2 , image 3 As shown, a composite material structure of a scaffold, the scaffold is composed of a plurality of uprights 1 and crossbars 2, wherein the uprights 1 are fixedly provided with a coupling plate 10 through a sleeve, and the coupling plate 10 is that a number of assembly through holes 101 are sequentially pierced on the peripheral surface, and the cross bar 2 is equipped with assembly joints 20 at the ends. 201 is provided with a snap-through groove 202, and its cross bar 2 is clipped on the joint plate 10 of the column 1 by using the combined slot 201 of the assembly joint 20, and the snap-through slot 202 is communicated with the assembly through-hole 101 correspondingly, and then Provide a bolt 30 to be inserted and fixed, so that the column 1 and the cross bar 2 are connected and fixed to each other through the joint plate 10 and the assembly joint 20, and a scaffold structure is completed, wherein the joint plate 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com