Automatic weft-direction wave-shaped fabric production mechanism of sample weaving machine

A technology for corrugated fabrics and prototype looms, applied in small looms, looms, textiles, etc., can solve the problems of simple operation method, single pattern, low degree of automation, etc., achieve strong stereoscopic visual effect, and realize style design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

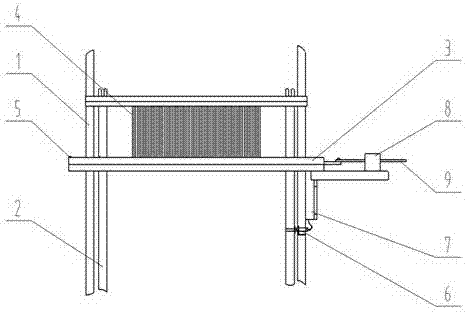

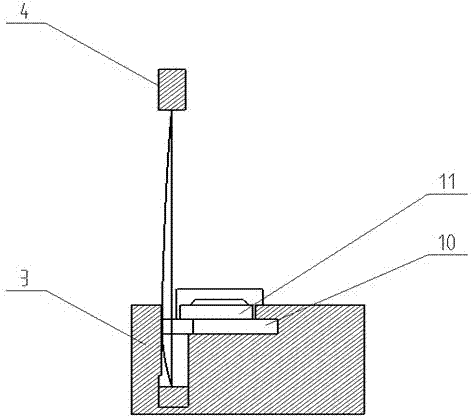

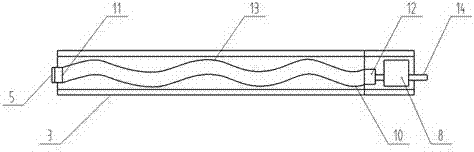

[0018] Such as figure 1 The automatic production mechanism of the weft wave fabric of the sample loom shown includes the main body of the sample loom, PLC7, a wave slider 10, a stepper motor 8 driven by PLC7, and the wave slider 10 is fixed to the screw 9 of the stepper motor 8 Connection, installed on the sley 3 in the horizontal direction, perpendicular to the deformed reed 4. The corrugated slide block 10 is an integrally formed elongated shape, and an arc track 13 is arranged on one side in contact with the deformed reed 4, and the front end of the arc track 13 is provided with a baffle plate, and the baffle plate and the arc track 13 front ends are connected with screw rods. The sley 3 is provided with a groove for the wave-shaped slider 10 to slide freely, and the groove runs through the sley 3 . The describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com