An automatic spinneret shoveling device and method

A technology of spinneret and shovel plate, which is applied in the direction of spinneret assemblies, textiles and papermaking, etc. It can solve the problems of high requirements for operators, impact on employees' health, time-consuming and laborious cleaning, etc., and achieve low requirements and ensure health. Healthy, labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

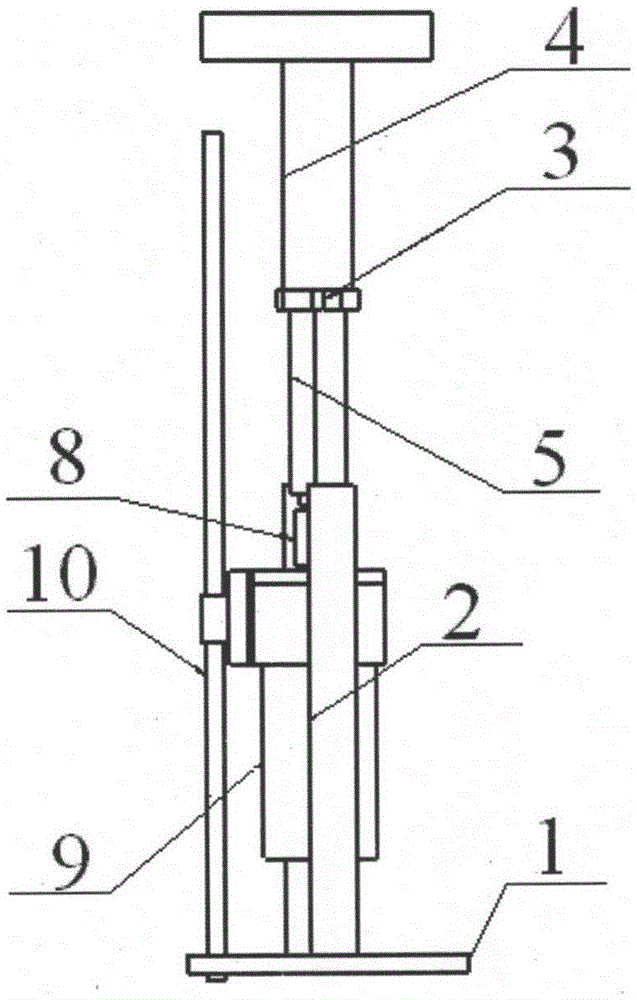

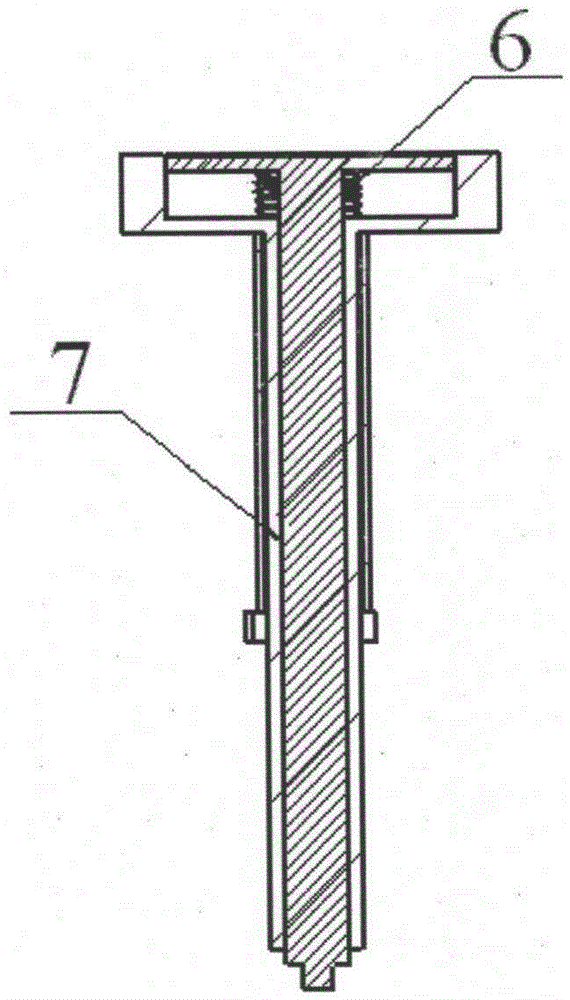

[0015] The present invention is an automatic spinneret shoveling device, such as figure 1 , figure 2 As shown, it consists of two parts: a lifting device and a rotating device. The lifting device is arranged as a spring 6, a shovel handle 5, a support, a cylinder 2, a base 1, and a guide rail 10 from top to bottom. Wherein, the support is that the sleeve 4 is in contact with the support frame 3, and the sleeve 4 can rotate. A guide rail 10 and two air cylinders 2 are installed on the base 1, and the triangular structure formed by the two air cylinders 2 and the guide rails 10 ensures the stability of the rotation during the rotating operation. The telescopic end of the cylinder 2 is connected with the sleeve 4 through the support frame 3, and the sleeve 4 is covered with a shovel handle 5, that is, the lower end of the shovel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com