A kind of high temperature molten salt preparation device and method

A technology for high-temperature molten salt and preparation devices, applied in heating devices, solar thermal devices, chemical instruments and methods, etc., can solve problems such as inability to mass-produce, and achieve the effects of particle filling, cost reduction, and pressure control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

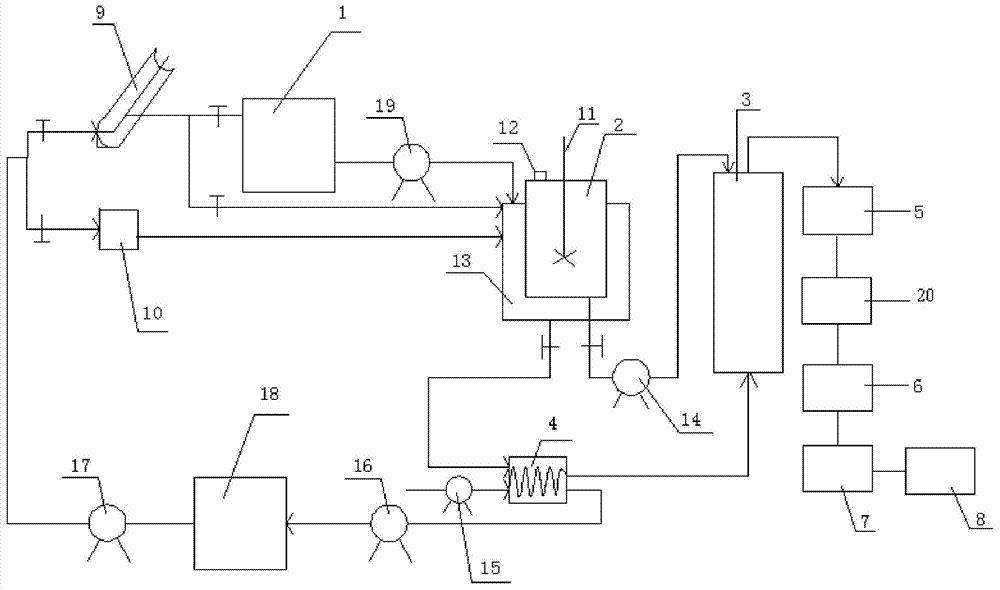

[0042] The present invention will be described below in conjunction with the accompanying drawings. The following examples are provided in order to further understand the present invention better, are not limited to the best implementation mode, and do not limit the content and protection scope of the present invention, anyone under the inspiration of the present invention or use the present invention Any product identical or similar to the present invention obtained by combining features of other prior art falls within the protection scope of the present invention.

[0043] figure 1 It is a schematic diagram of the structure of the high-temperature molten salt preparation device of the present invention, such as figure 1 As shown, the high-temperature molten salt preparation device of the present invention includes a mobile electric heat tracing 10, a molten salt tank 2 with an interlayer 13, a jet mill dryer 3, a hot air generator 4, a granulation device 5, a cooling device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com