Ultra-wide fore-fulcrum hanging basket

A front fulcrum and wide-width technology, which is applied in the field of ultra-wide front fulcrum hanging baskets, can solve the problems of difficulty in meeting the requirements of large thrust transmission functions, large horizontal force components of stay cables, and heavy weight, etc., to reduce the walking of the hanging basket Jacking thrust, satisfying large horizontal force component thrust, reducing weakening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

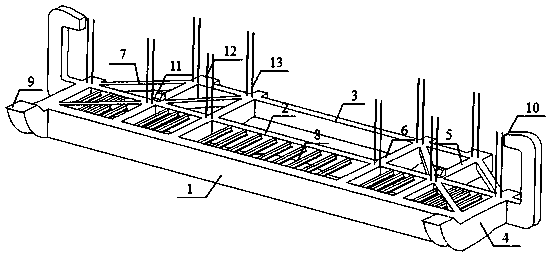

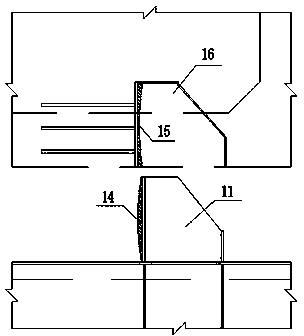

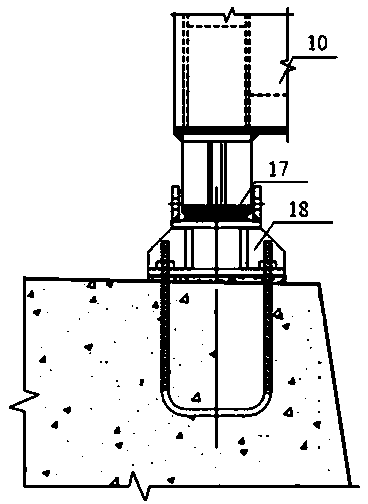

[0019] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-3 As shown, an ultra-wide front fulcrum hanging basket includes a front crossbeam 1, a middle crossbeam 2, a rear crossbeam 3, two groups of main longitudinal beams 4, two groups of side and secondary longitudinal beams 5, and two groups of middle and secondary longitudinal beams 6. Web bars 7 are connected between the longitudinal beams 4, side secondary longitudinal beams 5, and middle secondary longitudinal beams 6, small longitudinal beams 8 are connected between the front beam 1 and the middle beam 2, and the two ends of the middle beam 2 are respectively fixedly connected There is a C-shaped walking hook 10; the front end of the main longitudinal beam 4 is fixedly connected with an arc-shaped head 9, and the rear end of the side secondary longitudinal beam 5 is provided with a walking anti-roller 12; A wedge-shaped thrust key 11 is fixedly connected, and a wedg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com