Roller adjustable frame structure of carding machine

A rack structure, adjustable technology, applied in fiber processing, deburring devices, textiles and papermaking, etc., can solve problems such as falling on the rack, unsafe hidden dangers, unfavorable adjustments, etc., to reduce installation and improve carding Efficiency and shortening of working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

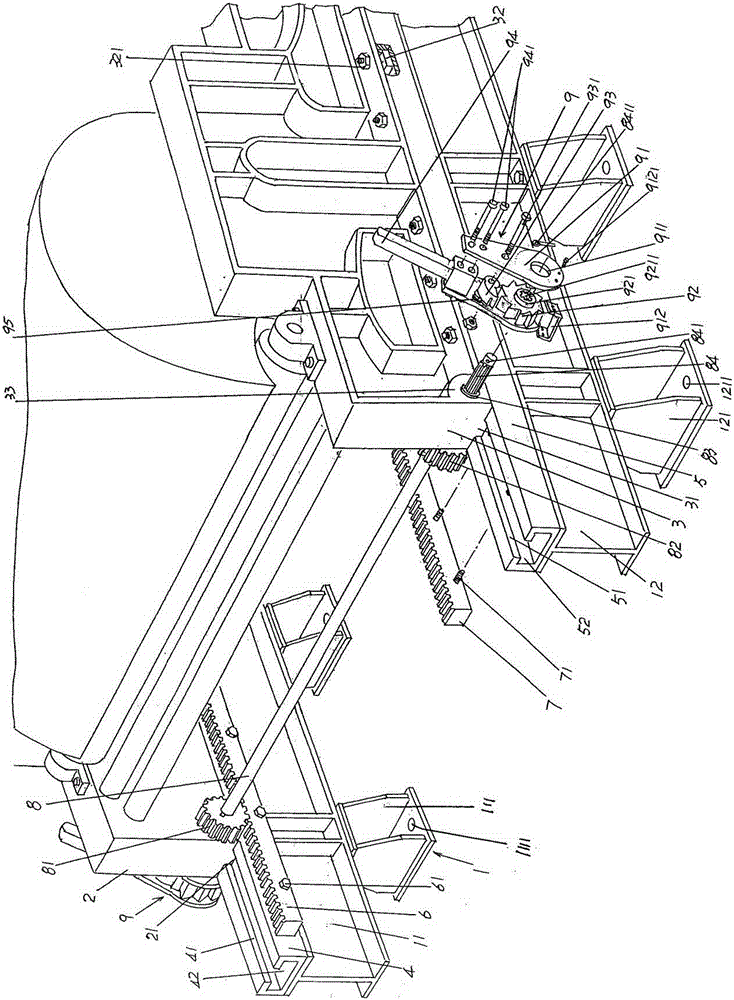

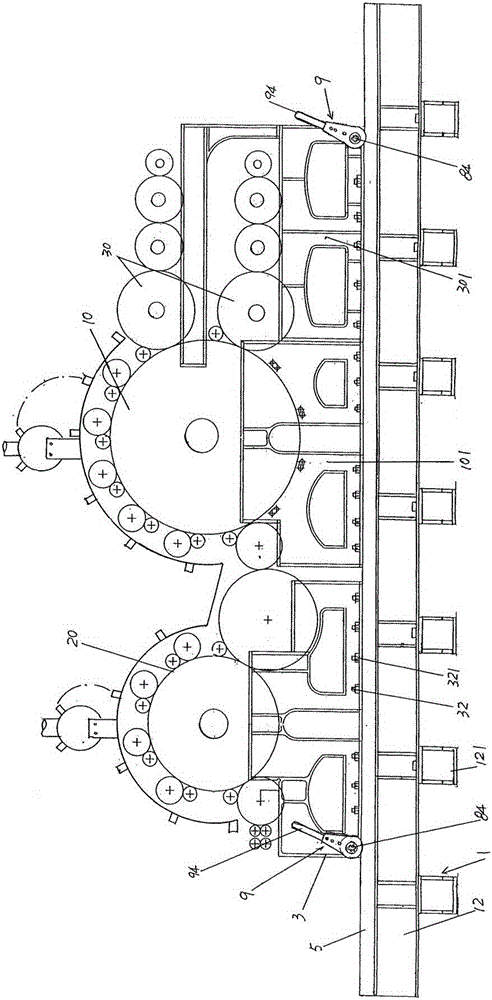

[0025] See figure 1 , a frame 1 is given, and the frame 1 includes a left bottom beam 11 and a right bottom beam 12, that is to say, the frame 1 is composed of left and right bottom beams 11, 12, and the left and right bottom beams The beams 11, 12 are kept parallel to each other in the length direction. When in use, the left bottom beam 11 and the right bottom beam 12 are supported on the floor of the place of use.

[0026] It can be seen from the schematic diagram of the figure that the cross-sectional shapes of the left bottom beam 11 and the right bottom beam 12 are both I-shaped, that is, I-shaped steel is used as the left bottom beam 11 and the right bottom beam 12. figure 1 In the middle, a group of left bottom beam supporting feet 111 and a group of right bottom beam supporting feet 121 are shown, and a group of left bottom beam supporting feet 111 are arranged in a spaced state along the length direction of the left bottom beam 11, and are connected with the left botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com