Red oil sauerkraut instant noodle seasoning pack and preparation method thereof

A seasoning package and instant noodle technology, applied in red oil pickled vegetable instant noodle seasoning package and its preparation field, can solve the problems of slow release of capsaicin, soft spicy feeling, easy to choke throat, etc., to improve quality stability, improve spiciness distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

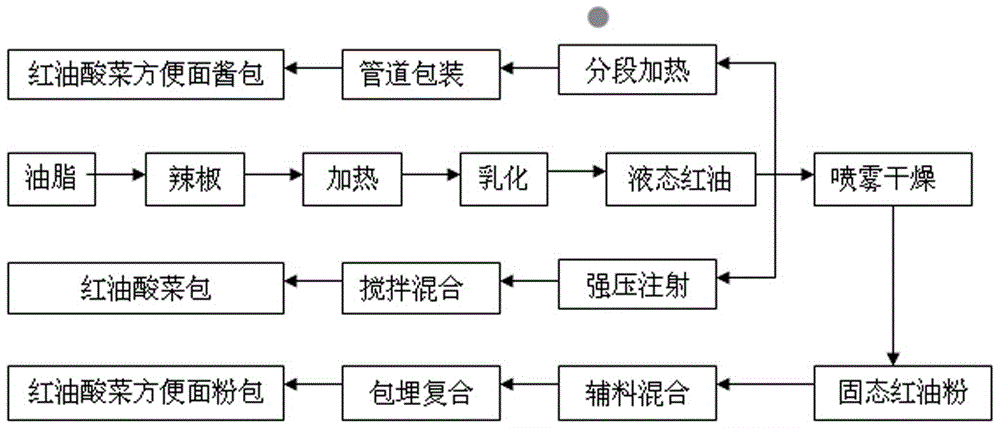

Method used

Image

Examples

preparation example Construction

[0032] 1. Preliminary red oil preparation.

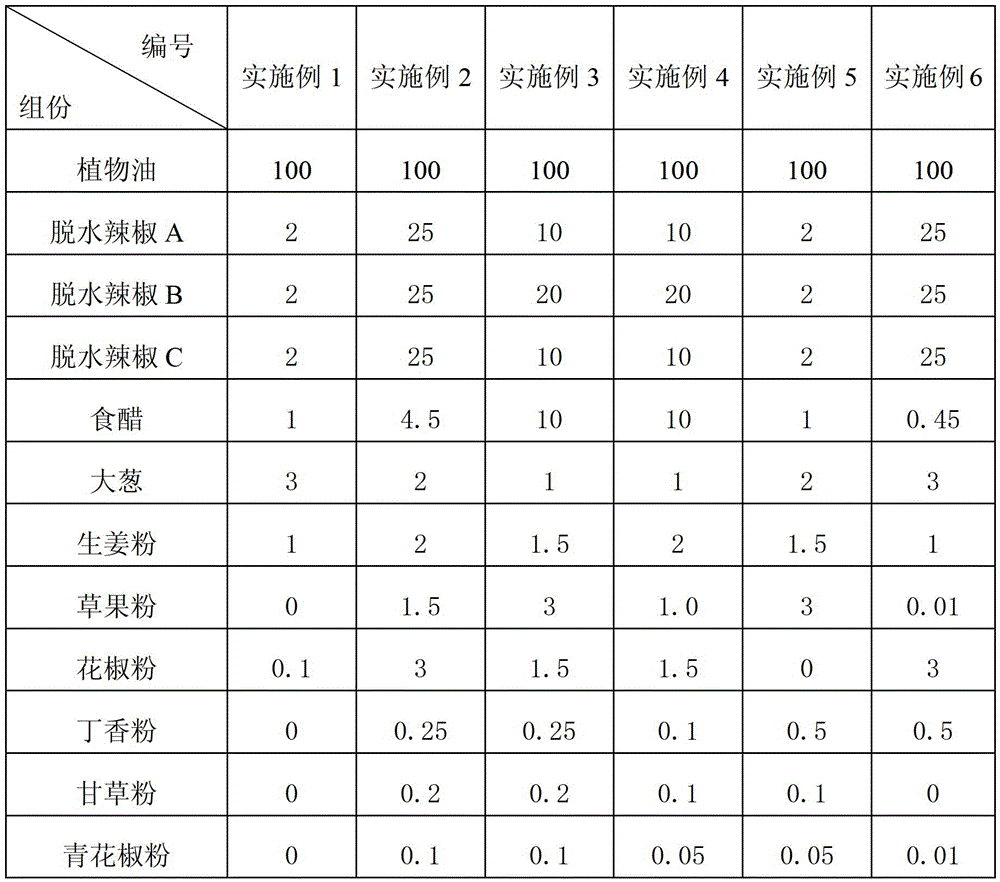

[0033] According to the following steps, the primary red oil was prepared with the component contents described in Examples 1-6 in Table 1, and the component contents in Table 1 are parts by weight of each component.

[0034] (1) Select dehydrated pepper A, remove impurities, and crush it with a pulverizer to 40-60 meshes, dehydrated peppers B to 100-200 meshes, and bake dehydrated peppers C in an oven at 150-180°C for 20 minutes until burnt black and dry. After the pepper is burnt and spicy, it is crushed to 60-80 meshes, and the above-mentioned three kinds of crushed peppers are mixed in proportion until uniform, and the pepper powder is obtained for use;

[0035] (2) Heat the refined vegetable oil to 120-250°C, turn off the heat, and add the following ingredients in sequence according to the amount. During the addition of the ingredients, the stirring paddle is stirred at 20-100 rpm. The ingredients are: prepared in (1) The resu...

Embodiment 7

[0042] 80 parts of preliminary red oil, 5 parts of milk powder, 10 parts of starch, 3 parts of emulsifier, and 0.2 part of flavor enhancer ethyl maltol prepared in specific example 1 were placed in a high-speed shearing machine at a speed of 4500 rpm Carry out homogenization to disperse and emulsify the red oil well to obtain liquid red oil;

[0043] Prepare another portion of liquid red oil according to the above ratio, and then spray dry the liquid red oil. The spray drying parameters are: feed temperature 185°C, discharge temperature 145°C, hot air flow rate 26.47m 3 / h, feed flow rate 0.20L / h, obtain solid red oil powder.

Embodiment 8

[0045] Put 10 parts of preliminary red oil, 10 parts of milk powder, 5 parts of starch, 1 part of emulsifier, and 0.1 part of flavor enhancer ethyl maltol prepared in specific example 1 into a high-speed shearing machine at a speed of 3500 rpm Carry out homogenization to disperse and emulsify the red oil well to obtain liquid red oil;

[0046] Prepare another portion of liquid red oil according to the above ratio, and then spray dry the liquid red oil. The spray drying parameters are: feed temperature 185°C, discharge temperature 145°C, hot air flow rate 26.47m 3 / h, feed flow rate 0.20L / h, obtain solid red oil powder.

[0047] Three, the preparation of sauce package.

[0048] In parts by weight, mix 10-80 parts of refined vegetable oil and 2-8 parts of lard and heat to 100-180°C, then add 2-10 parts of liquid red oil prepared in Example 7 or Example 8 , 6-8 parts of pickled pepper, 4-9 parts of pickled ginger, 1-5 parts of turmeric powder, 1-4 parts of table salt, 8-12 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com