Evaluation method for flavor harmony of diluted beer after high-concentration brewing

A technology of beer flavor and evaluation method, which is applied in measurement devices, instruments, and analysis by nuclear magnetic resonance, etc., to achieve the effect of rigorous coordination and removal of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Establishment of sensory evaluation method

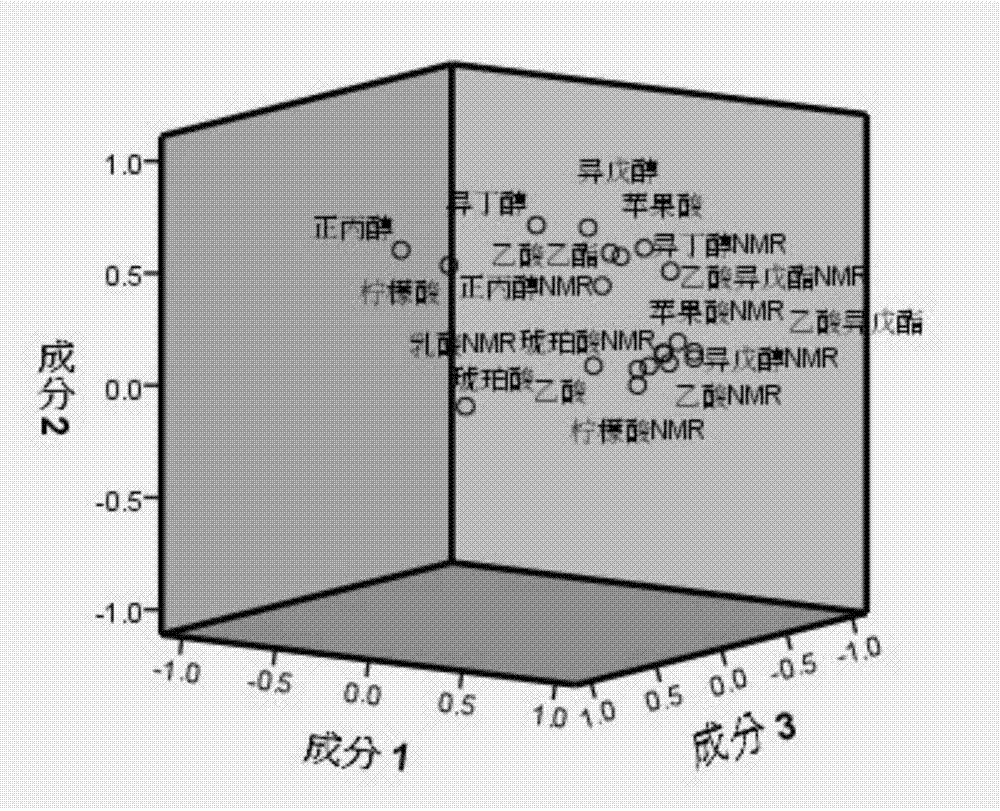

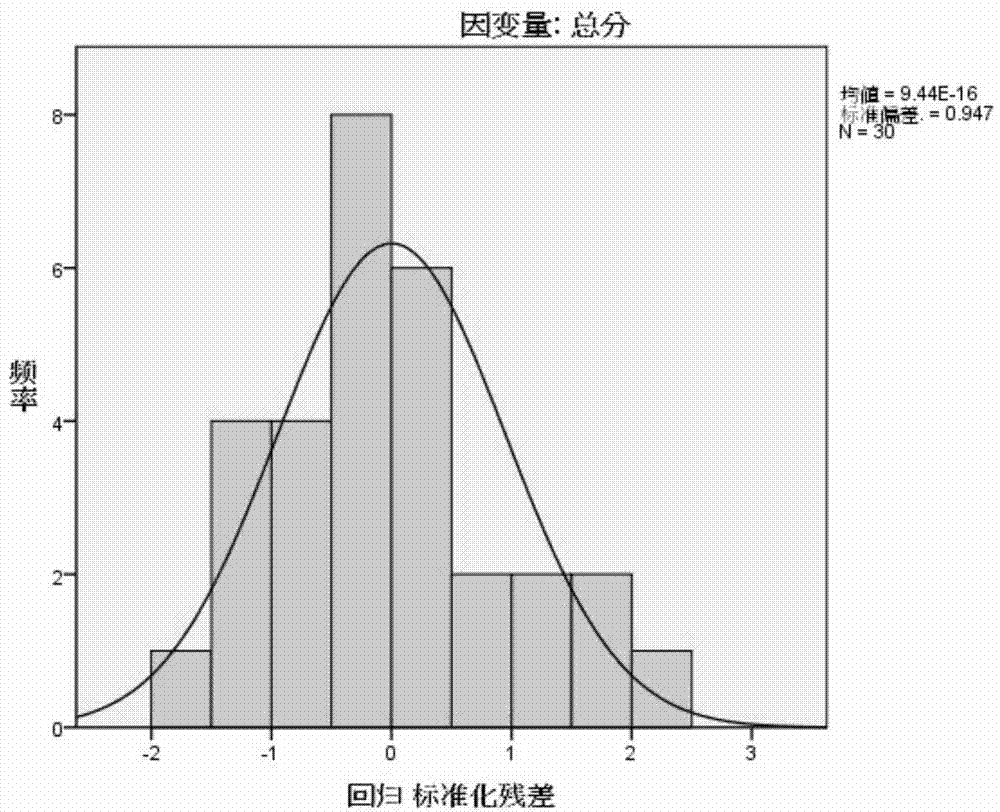

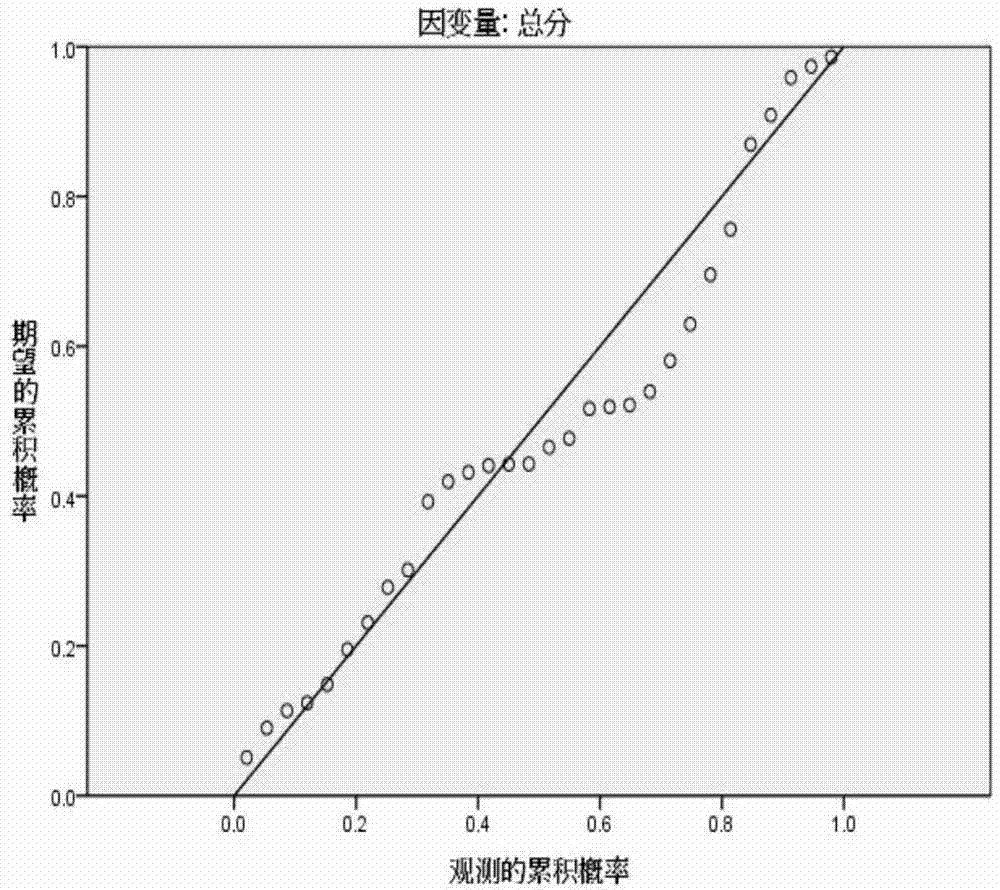

[0046] (1) select 30 kinds of commercially available beers, select the content of malic acid, lactic acid, acetic acid, citric acid, succinic acid, ethyl acetate, isoamyl acetate, isobutanol, isoamyl alcohol, n-propanol in the wine sample and 20 variables such as chemical shift information are used as initial independent variables, and through the variance maximum orthogonal rotation, the predicted variables obtained maximize the load in different components, and select as few components as possible, but can explain as many variables as possible Variance (generally greater than 70%), and principal components with eigenvalues ≥ 1 can be considered statistically significant.

[0047] Table 2 is the contribution rate of each principal component to the variance generated by the maximum orthogonal rotation of the variance of the 20 original variables. Among them, the cumulative variance contribution rate of the first three prin...

Embodiment 2

[0085] Example 2 Research on Dilution Process after High Concentration Brewing

[0086] The laboratory pilot scale simulates the production of 180L original wort with a concentration of 22°P high-concentration fermented liquid, and adopts the following dilution processes for the filtered wine base:

[0087] 1) 22°P→8°P; 2) 22°P→18°P→8°P; 3) 22°P→15°P→8°P; 4) 22°P→12°P→8° P; 5) 22°P → 18°P → 12°P → 8°P.

[0088] Among them, during the dilution process, after each level of dilution, the wine sample was hydrated for 24 hours before subsequent dilution or detection.

[0089] For the 5 kinds of diluted wine samples obtained by different dilution processes, the compressed water peak NMR detection, quantitative detection and sensory evaluation experiments were respectively carried out, and the detection data were brought into the evaluation method established above. The results are shown in Table 9:

[0090] Table 9 Prediction results and sensory evaluation scores of wine samples w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com