Threaded sleeve clutch

A clutch and threaded sleeve technology, applied in the field of threaded sleeve clutches, can solve the problems of improved transmission efficiency, low power transmission efficiency, and difficult separation of gears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

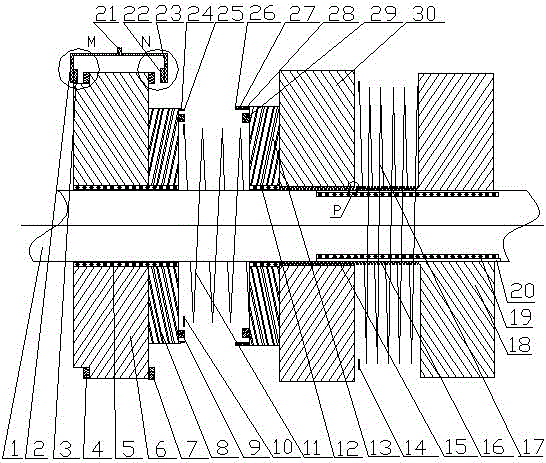

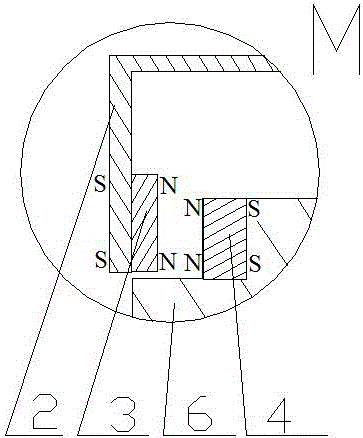

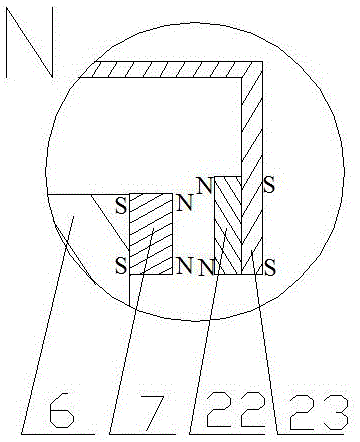

[0023] exist figure 1 In the embodiment shown in -8: the threaded sleeve clutch includes a group of driving wheels and a group of driven wheels adjacent to the driving wheels and a group of driven wheels adjacent to the driven wheels, and the driving wheels include active Wheel 6 and driving wheel secondary wheel 8, driven wheel group comprises driven wheel 30 and driven wheel secondary wheel 13, driven wheel group comprises driven wheel 18 and driven wheel rotation axle sleeve 20, driving wheel 6, driving wheel secondary wheel 8, driven wheel 30 1, driven wheel auxiliary wheel 13, driven wheel 18, driven wheel shaft sleeve 20, driven wheel spring 11, driven wheel spring 17 are all set on the same fixed shaft 1, and are coaxial with the fixed shaft 1; it is characterized in that: active A driven wheel spring 11 is arranged between the wheel 6 and the driven wheel 30, a driven wheel spring 17 is arranged between the driven wheel 30 and the driven wheel 18, the driving wheel 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com