Six-wheel double-drive mini-tiller

A technology of micro tillage machine and middle wheel, which is applied in the direction of steering mechanism, steering rod, transportation and packaging, etc., and can solve problems such as falling into the mud, danger, slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

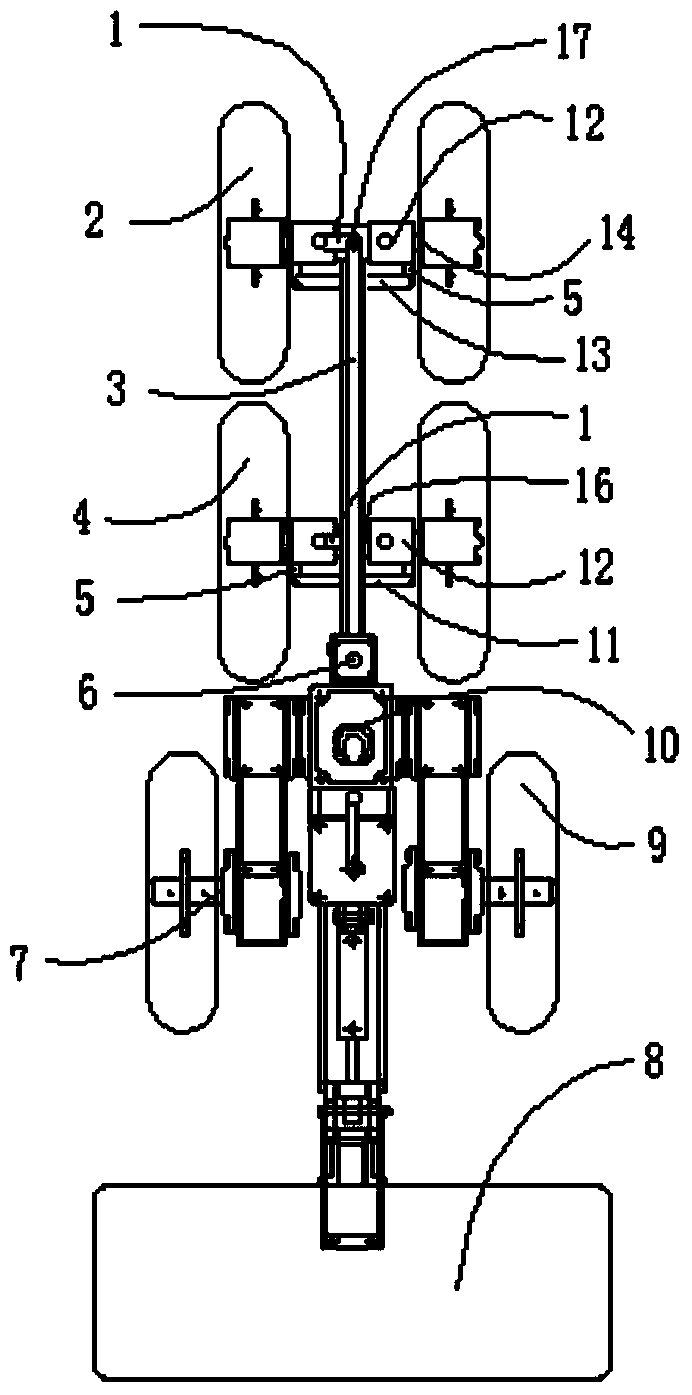

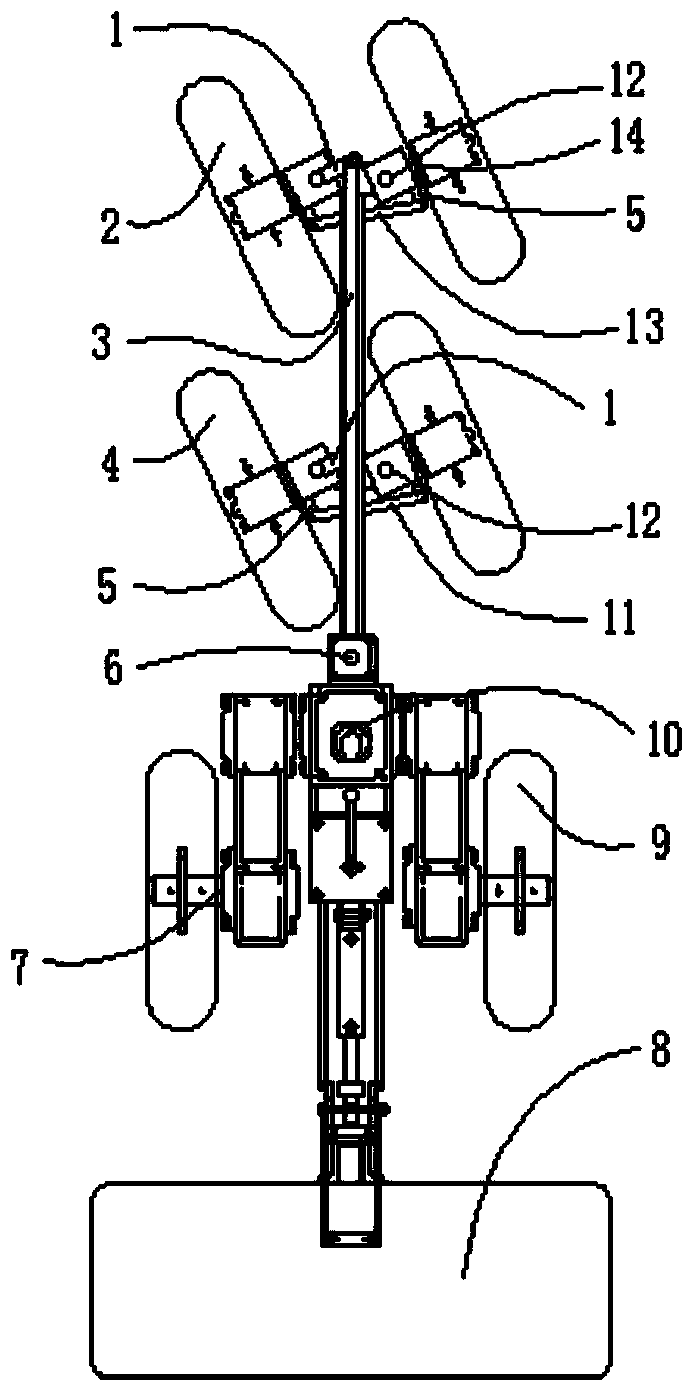

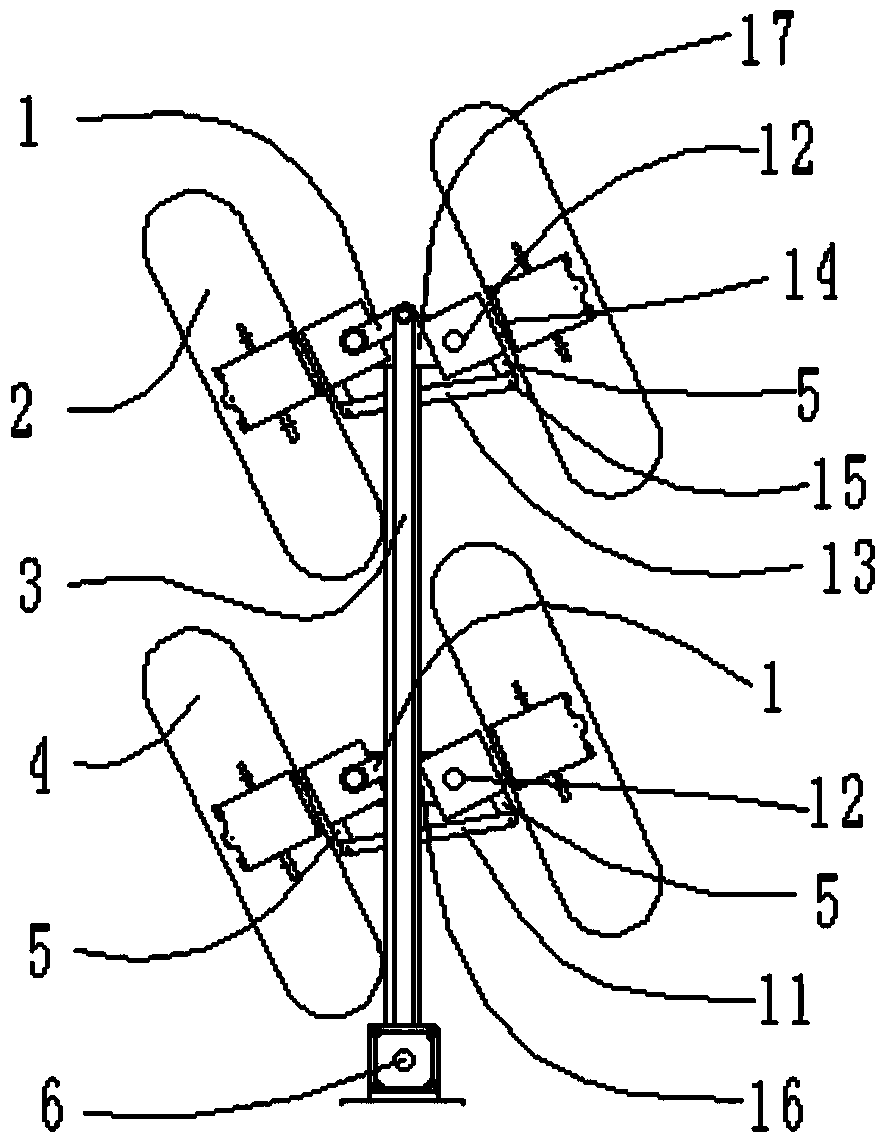

[0024] Such as figure 1 , figure 2 , image 3 As shown, a six-wheel two-drive micro-cultivator includes: a car body (not shown in the figure), road wheels and a rotary tiller 8. The road wheels are three pairs, including front wheels 2, middle wheels 4 and rear wheels 9. The front wheel 2, the middle wheel 4 and the rear wheel 9 are respectively arranged on the front side, the middle part and the rear side of the bottom of the car body. The driving force of the drive wheel. The rotary tiller 8 is arranged at the rear of the micro tiller, and the tiller moves with the rotary tiller 8 to carry out the rotary tillage operation during the traveling.

[0025] Front wheel 2 and middle wheel 4 are arranged on the car body by steering gear, as figure 1 or figure 2 As shown, the steering device includes: steering gear 6, front beam 17, middle beam 16, steering knuckle 12, steering tie rod I13, steering tie rod II11, steering straight tie rod 3, wherein:

[0026] The steering ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com