Composite tablet press

A tablet press and composite technology, applied in the field of presses, can solve the problem of powder not being reusable and wasteful, and achieve the effect of recycling powder raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

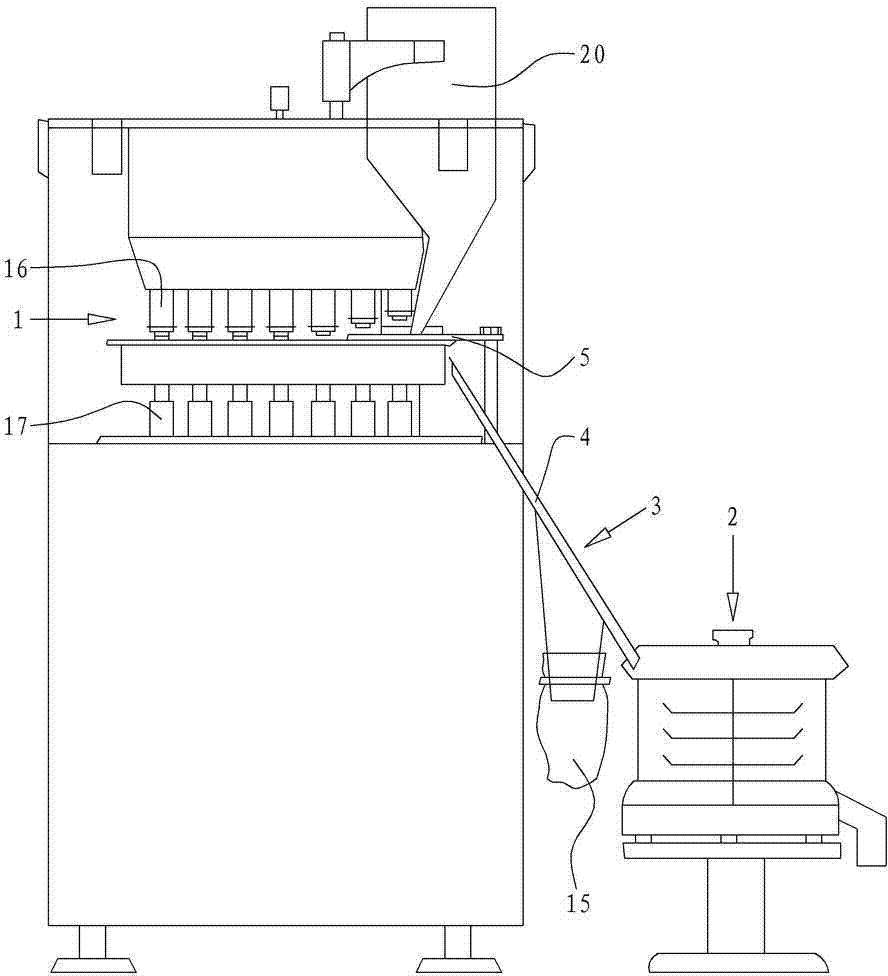

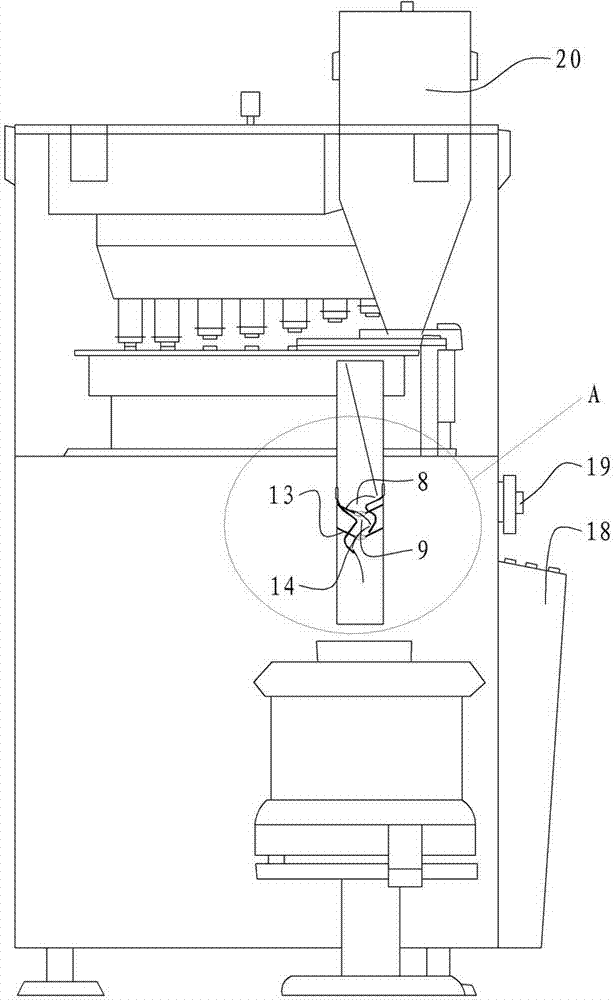

[0016] The composite tablet press of the present embodiment, such as figure 1 with figure 2 As shown, it includes a sheet compression molding device 1 and a sheet collection device 2 located below the sheet compression molding device 1 . A sheet discharging device 3 is arranged between the sheet pressing and forming device 1 and the sheet collecting device 2 . The film output device 3 includes a lower film groove 4 placed obliquely and a scraper plate 5 for scraping the formed sheet into the lower film groove.

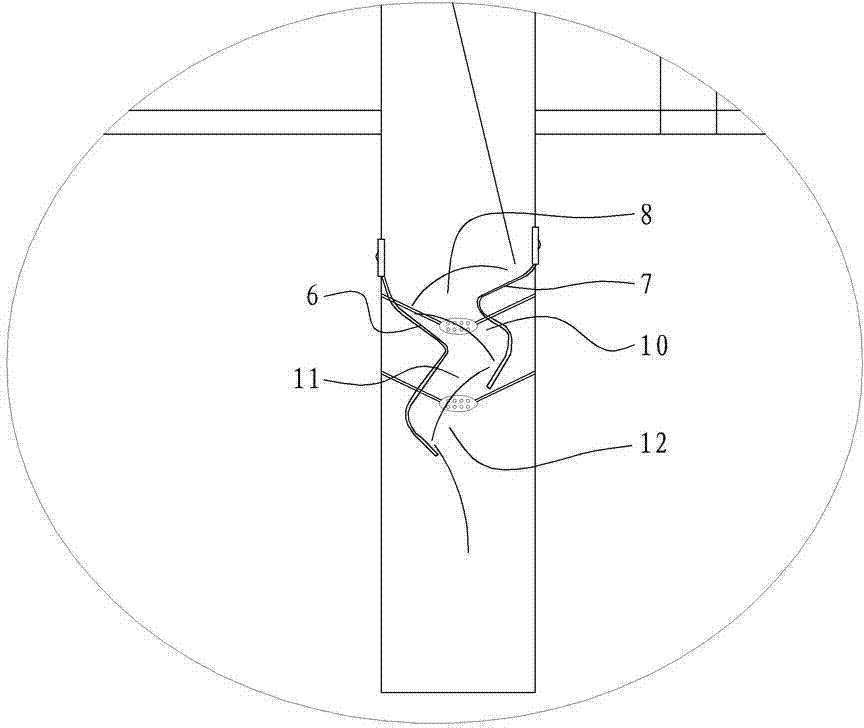

[0017] Such as image 3 with Figure 4 As shown, the entrance of the lower film groove 4 is provided with an adjusting piece (not marked on the figure) for adjusting the falling angle of the film. A left vibrating plate 6 and a right vibrating plate 7 are arranged in the lower plate groove 4 opposite to each other. Both the left vibrating piece 6 and the right vibrating piece 7 are composed of at least two vibrating pieces 21 arranged up and down in a row. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com