Hand-held power tool with height adjustment device

A technology of hand-held machine tools and height adjustment devices, which is applied in the direction of manufacturing tools, portable mobile devices, special forming/shaping machines, etc. Comfort, difficulty in operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

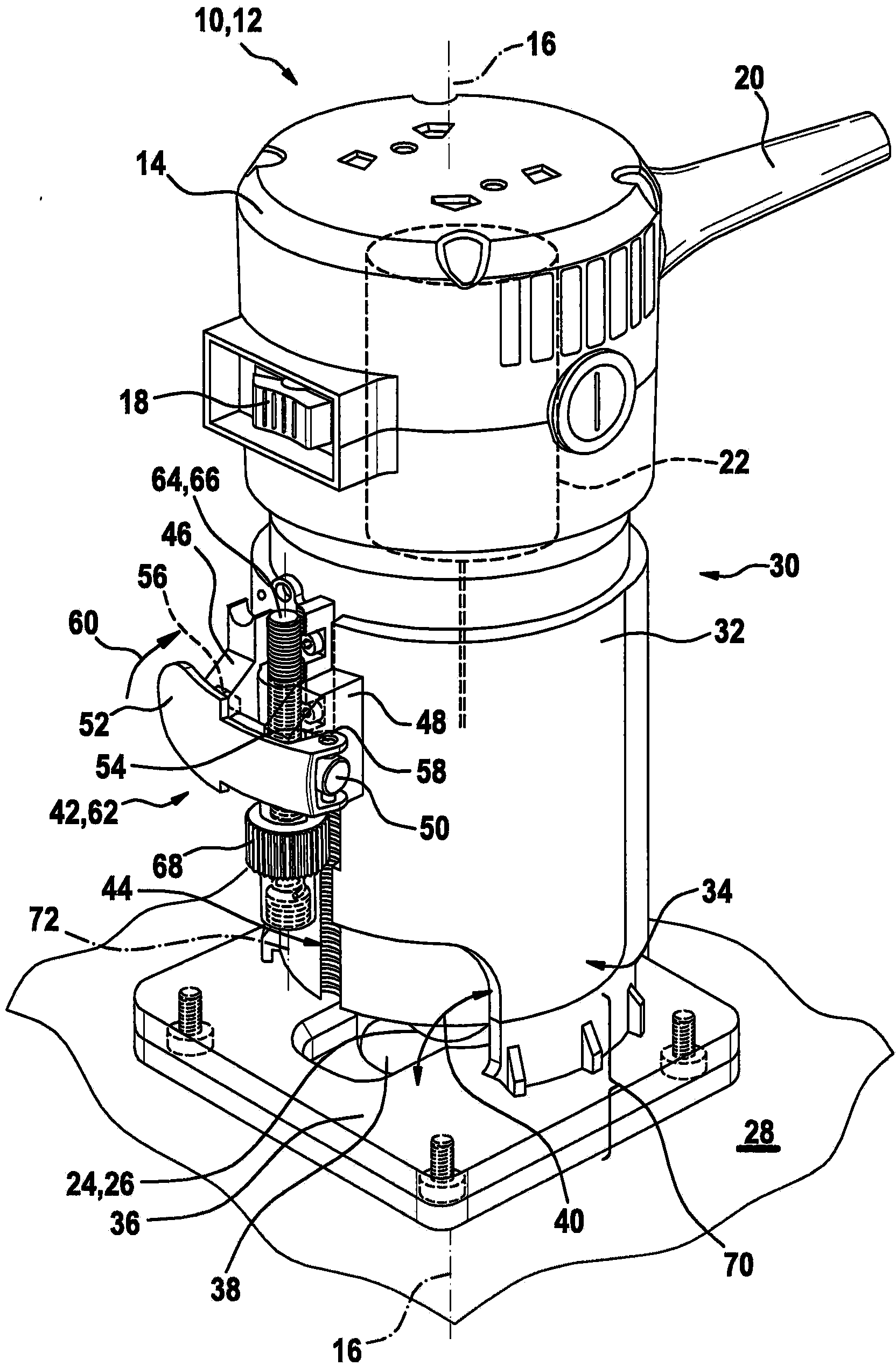

[0042] figure 1 A hand-held power tool 10 is shown, for example, in the form of a router 12 , which illustratively has a machine housing 14 , a mains switch 16 and a mains feeder 20 . However, it should be pointed out that the invention is not limited to grid-operable routers 12, but is more applicable to grid-operable routers or hand-held power tools that can be connected to An associated accumulator is mechanically and electrically connected for power supply or has an alternative pneumatic drive.

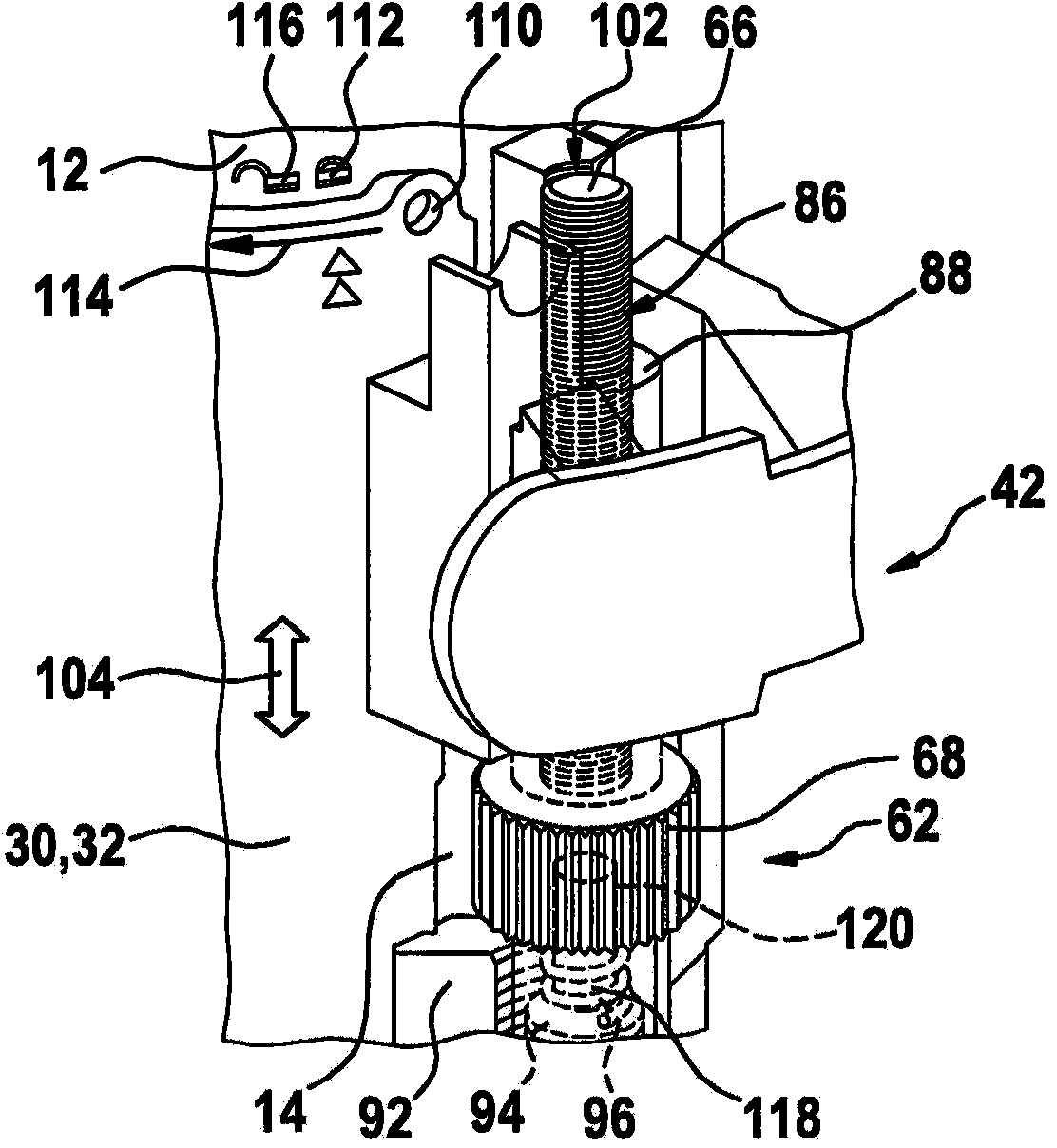

[0043] By means of the drive motor 22 , an insert tool 26 of the router 12 , which is designed here only by way of example as a milling tool 24 , can be driven at a high rotational speed. For precise, plane-parallel guidance of the router 12 on the workpiece 28 , the router has a support device 30 having an at least substantially hollow-cylindrical support element 32 for receiving the machine housing 14 at least in sections. The support device 30 is preferably made of a sufficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com