Shrimp Processing System And Methods

A technology of processing system and processing path, applied in shrimp/lobster processing, crustacean processing, character and pattern recognition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

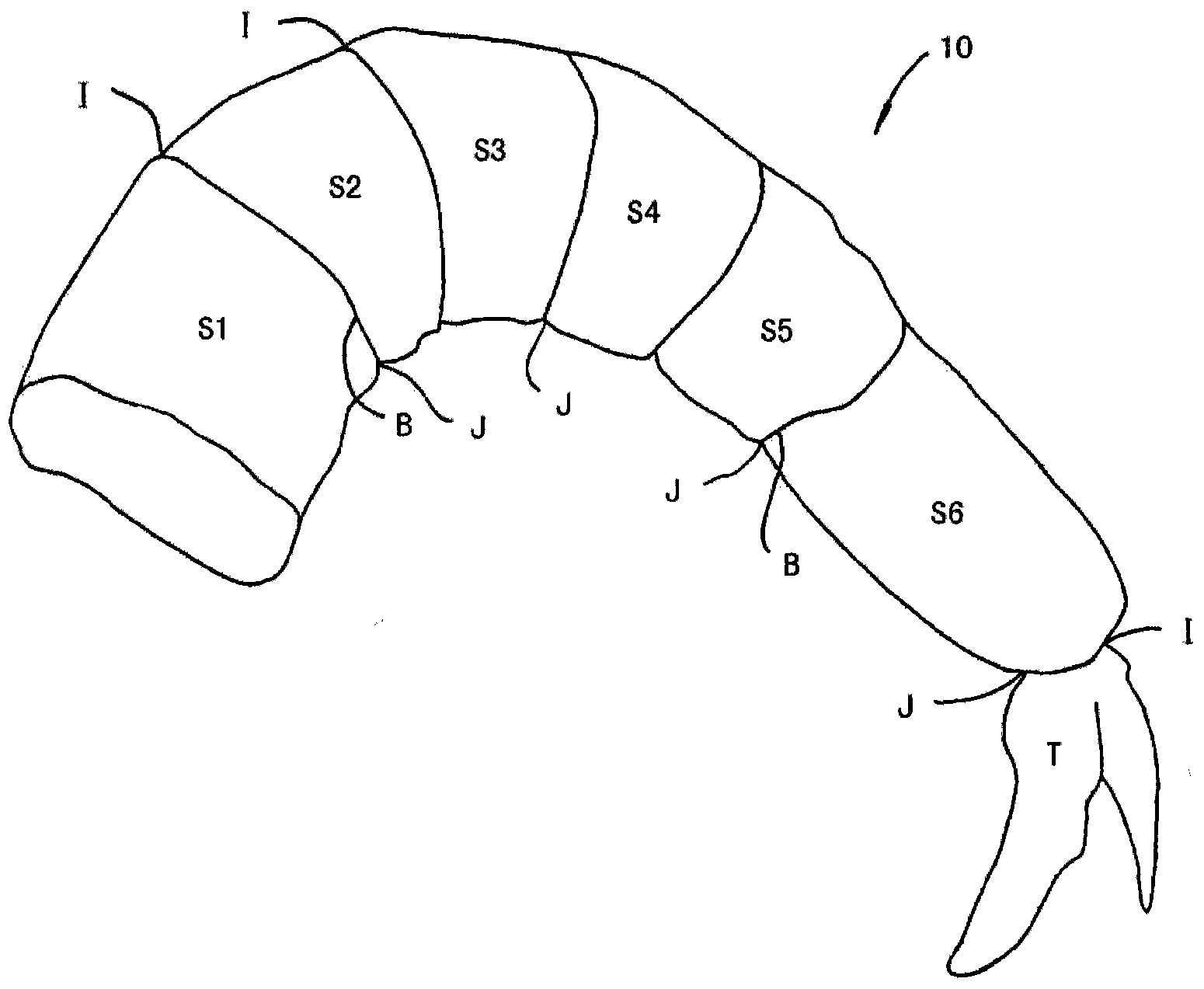

[0015] figure 1 Anatomical diagram showing a peeled, or shelled and headed shrimp. A complete shrimp meat 10 includes 6 main segments S1-S6 and tail segments T. The rostral segment S1 has the largest girth of all body segments; the telomere T is sometimes removed along with the shell during processing. Segments S1-S6 are commonly referred to as "somites". As with other features, boundaries B between adjacent segments are often discernible, as indentation I along the dorsum and depression J along the abdomen at the junction of adjacent segments.

[0016] One method of determining peel quality is by counting the number of contiguous segments of peeled shrimp exiting the peeler and classifying each peeled shrimp as high quality, medium quality, or low quality. For example, each shrimp with 6 complete somites S1-S6 (with or without all telsons) can be classified as high quality ( Figure 2A ); not high quality shrimp with complete somites S1-S5 plus more than half of telson S6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com