A ceramic heating sheet with temperature control

A technology of ceramic heating sheet and ceramic sheet, which is applied in the direction of electric heating device, ohmic resistance heating, ohmic resistance heating parts, etc., which can solve the problems of small heating area and low heating efficiency of heating sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

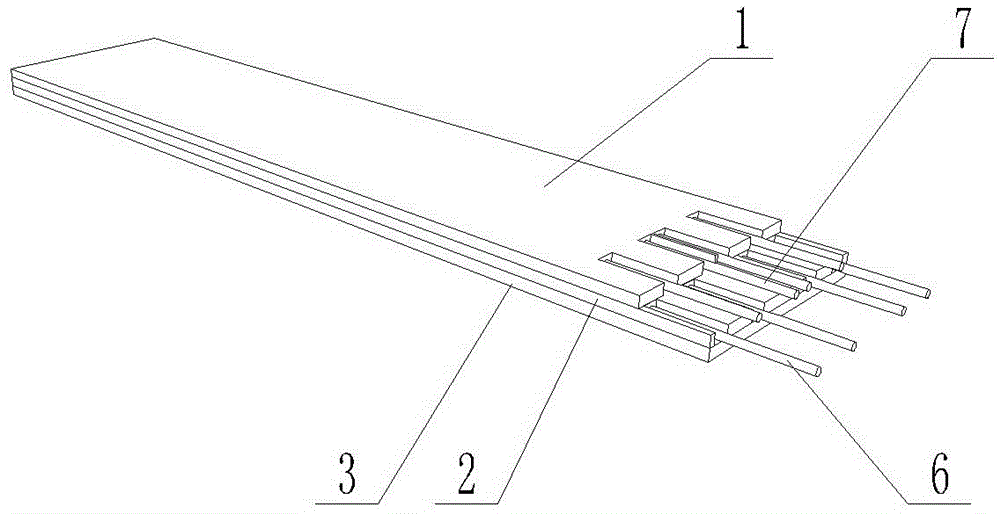

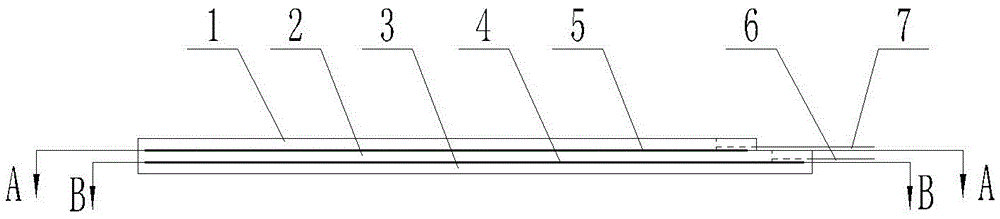

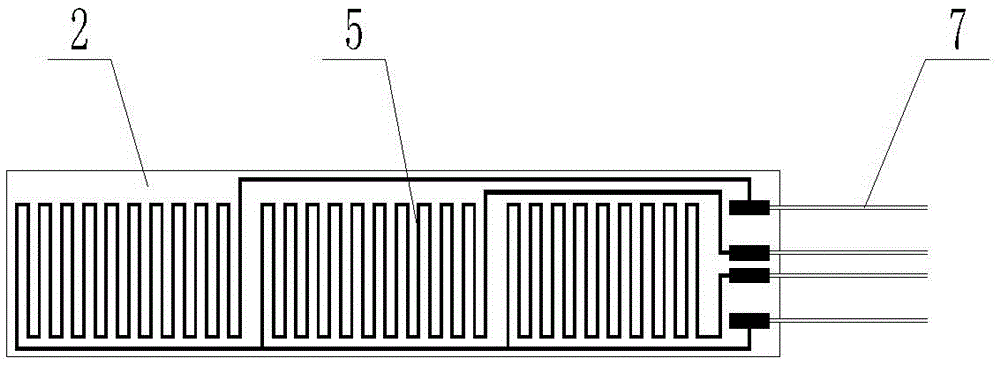

[0015] Figure 1 to Figure 4 The first specific embodiment of a ceramic heating sheet with temperature control of the present invention is given, which is composed of an upper ceramic sheet 1, a middle ceramic sheet 2, a lower ceramic sheet 3, a heating resistor 4, a temperature control resistor 5, a heating The plate structure composed of lead wire 6 and temperature control lead wire 7 is a planar plate structure in this embodiment. The upper ceramic sheet 1, the middle ceramic sheet 2, and the lower ceramic sheet 3 are stacked in sequence. There are three heating resistors 4, and each heating resistor 4 Electrically connected to a set of heating lead wires 6, correspondingly there are three temperature control resistors 5, each temperature control resistor 5 is electrically connected to a set of temperature control lead wires 7, the heating resistor 4 and the temperature control resistor 5 are respectively located on the front and back sides of the middle ceramic sheet 2 And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com