Barley tea and milk beverage, and its preparation method

A barley tea and milk beverage technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of never-before-seen liquid tea milk beverages, complicated processes, too many additives, etc., and achieves a fresh taste, simple process, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

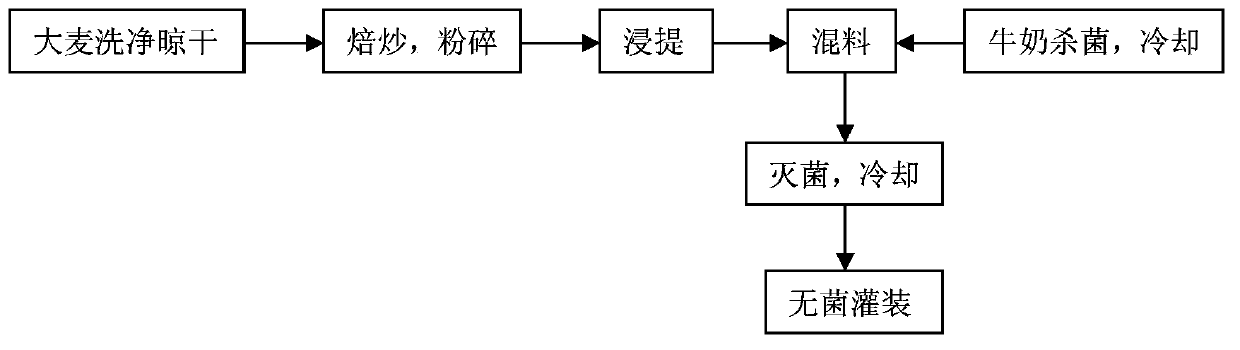

Method used

Image

Examples

Embodiment 1

[0032] Formula 1 (based on 1 ton of product)

[0033] Milk 350kg

[0034] Barley 10kg

[0035] Hydrate to 100%

[0036] The production process steps are as follows:

[0037] 1) Remove the sand from the barley, wash and dry.

[0038] 2) Roast the selected barley evenly with a slow fire, and stop when the barley has a strong aroma of wheat and the surface becomes browned.

[0039] 3) The barley obtained in step 2) is pulverized, sieved, and the barley in the barley is filtered out.

[0040] 4) Weigh a certain amount of barley obtained in step 3), add 4 times the quality of water, heat and boil for 20-30min, filter the extract, add 3.5 times the quality of water to the filter residue for secondary cooking, filter, Pour the filtrate into the primary filtrate, filter it again with a mesh cloth, and set aside.

[0041] 5) The milk is pasteurized and added to the batching tank after cooling. Add the tea filtrate obtained in step 4) into the batching tank, stir evenly, and repl...

Embodiment 2

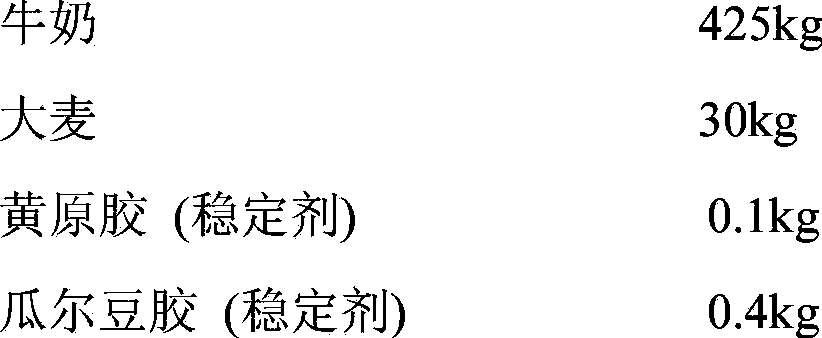

[0044] Formula 2 (based on 1 ton of product)

[0045] Milk 425kg

[0046] Barley 30kg

[0047] Hydrate to 100%

[0048] The production process steps are as follows:

[0049] 1) Remove the sand from the barley, wash and dry.

[0050] 2) Roast the selected barley evenly with a slow fire, and stop when the barley has a strong aroma of wheat and the surface becomes browned.

[0051] 3) The barley obtained in step 2) is pulverized, sieved, and the barley in the barley is filtered out.

[0052] 4) Weigh a certain amount of barley obtained in step 3), add 6 times the quality of water, heat and boil for 20-30min, filter out the extract, add 3 times the quality of water to the filter residue for secondary cooking, filter, Pour the filtrate into the primary filtrate, filter it again with a mesh cloth, and set aside.

[0053] 5) The milk is pasteurized and added to the batching tank after cooling. Add the tea filtrate obtained in step 4) into the batching tank, stir evenly, and re...

Embodiment 3

[0056] Formula 3 (based on 1 ton of product)

[0057] Milk 500kg

[0058] Barley 50kg

[0059] Hydrate to 100%

[0060] The production process steps are as follows:

[0061] 1) Remove the sand from the barley, wash and dry.

[0062] 2) Roast the selected barley evenly with a slow fire, and stop when the barley has a strong aroma of wheat and the surface becomes browned.

[0063] 3) The barley obtained in step 2) is pulverized, sieved, and the barley in the barley is filtered out.

[0064] 4) Weigh a certain amount of barley obtained in step 3), add 7 times the quality of water, heat and boil for 20-30min, filter out the extract, add 2 times the quality of water to the filter residue for secondary cooking, filter, Pour the filtrate into the primary filtrate, filter it again with a mesh cloth, and set aside.

[0065] 5) The milk is pasteurized and added to the batching tank after cooling. Add the tea filtrate obtained in step 4) into the batching tank, stir evenly, and repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com