Fixing device

A technology of fixing devices and positioning holes, applied in the direction of supporting structure installation, etc., can solve problems such as inconvenient operation, troublesome operation, damage to control equipment, etc., and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

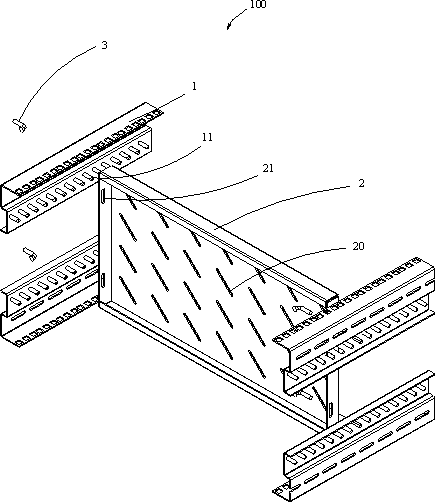

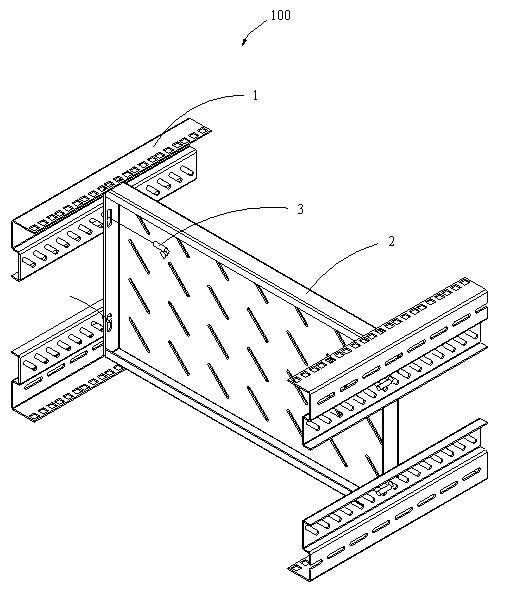

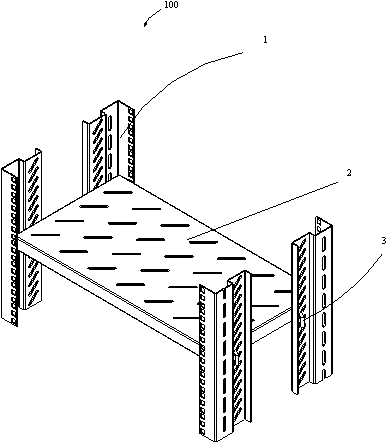

[0016] Please refer to Figure 1 to Figure 3 , the fixing device 100 of the present invention includes several uprights 1 , partitions 2 installed on the uprights 1 , and several safety pins 3 for installing the partitions 2 on the uprights 1 . The safety pin 3 is L-shaped. There are several positioning holes 11 arranged in a row on the column 1, and the partition plate 2 has several cooling holes 20 and connection holes 21 running through its side. The several connection holes 21 are respectively located at the corners of the partition plate 2. Flange (not indicated), the connection hole 21 is located on the flange. Such as Figure 4 As shown, the safety pin 3 has a first section 31 passing through the column 1 , a second section 32 bent and extended from the first section 31 , and a pin cap 33 located at the end of the second section.

[0017] The diameter of the pin cap 33 is larger than the diameters of the first segment 21 and the second segment 32 . The diameters of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com