A method for separating and purifying montmorillonite from calcium bentonite

A technology of calcium-based bentonite and montmorillonite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as poor crystallization, difficulty in separation and purification, and difficulty in purifying montmorillonite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

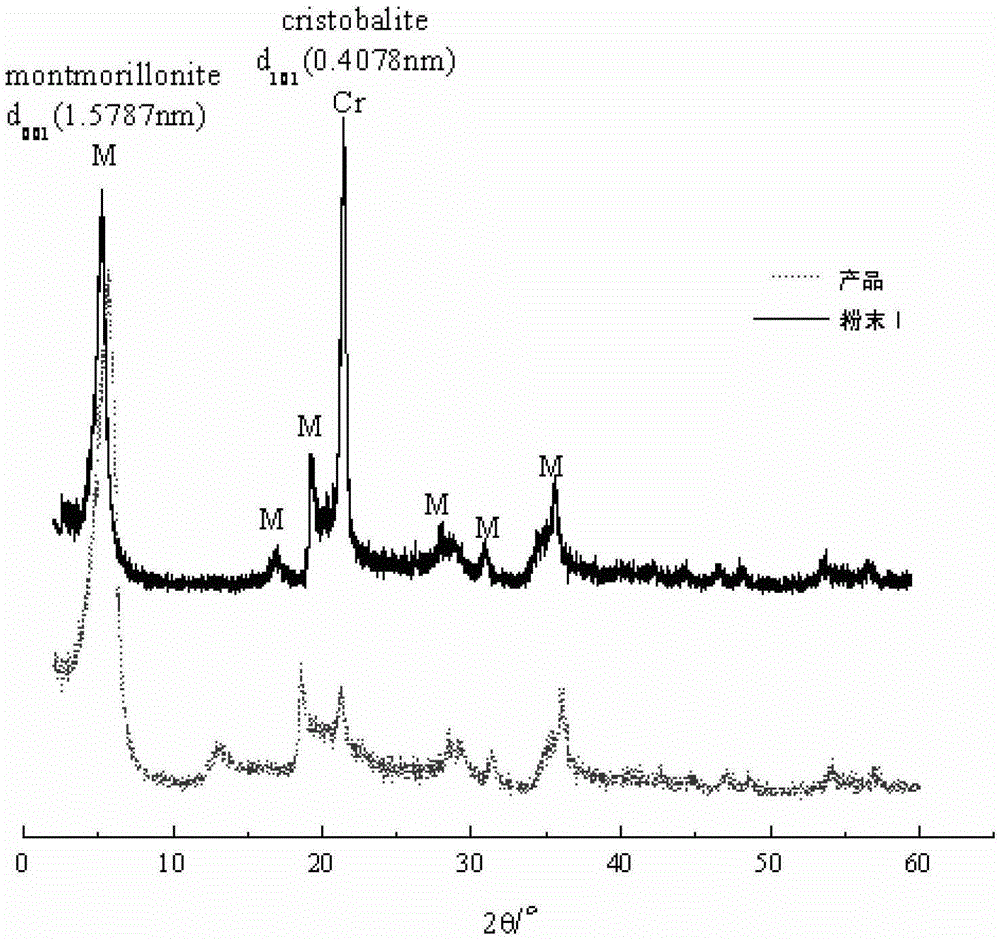

[0068] Make a slurry of bentonite raw ore and water at a solid-to-liquid weight ratio of 1:3, soak it in a container, stir it with a stirrer for 0.5 hours, let it stand for 8 hours, extract the slurry in the upper 10cm of the container, centrifuge it with a centrifuge, and dry it to remove large particles. Particle impurities to obtain montmorillonite to be purified.

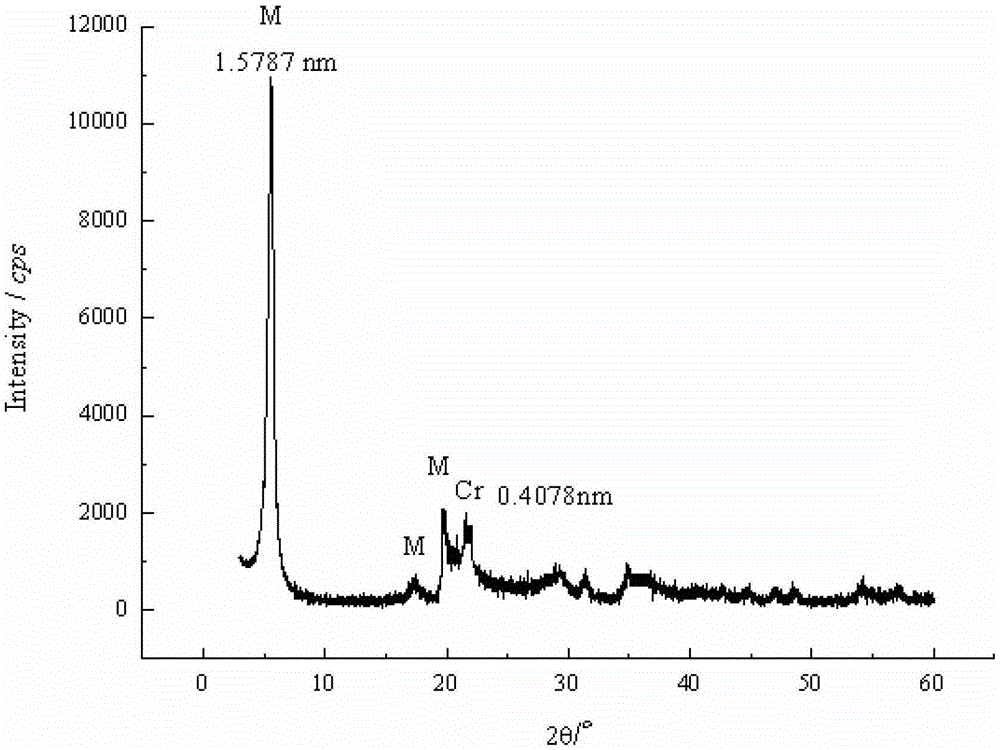

[0069] The montmorillonite and water to be purified are made into a suspension liquid with a solid-to-liquid weight ratio of 3:100, 1.0% mass fraction of sodium carbonate is added, and diluted sodium hydroxide solution is added to adjust the pH value of the slurry to 10.0. / min speed centrifugal dehydration to obtain powder I (preliminary purified montmorillonite);

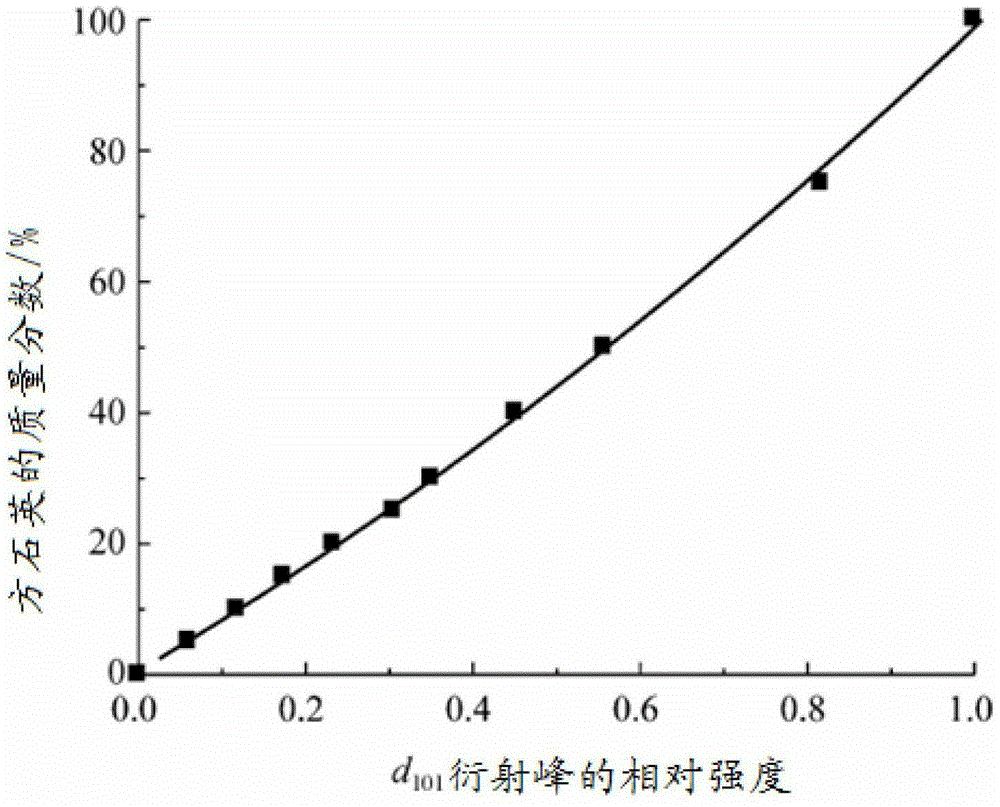

[0070] Make powder I and water into a suspension with a solid-to-liquid weight ratio of 3:100, add diluted sodium hydroxide solution to adjust the pH value of the slurry to 10.0, stir at a stirring speed of 5000r / min for 20min, and then use 80W ultr...

Embodiment 2

[0077] Make a slurry of bentonite raw ore and water at a solid-to-liquid weight ratio of 1:9, soak it in a container, stir it with a stirrer for 0.5 hours, let it stand for 8 hours, extract the slurry in the upper 10cm of the container, centrifuge it with a centrifuge, and dry it to remove large particles. Particle impurities to obtain montmorillonite to be purified.

[0078]The montmorillonite and water to be purified are made into a suspension liquid with a solid-to-liquid weight ratio of 3:100, 1.0% mass fraction of sodium carbonate is added, and diluted sodium hydroxide solution is added to adjust the pH value of the slurry to 10.3, and after 0.5 hours, the pH value of the slurry is adjusted to 1000 r / min speed centrifugal dehydration to obtain powder I (preliminary purified montmorillonite);

[0079] Make powder I and water into a suspension with a solid-to-liquid weight ratio of 3:100, add diluted sodium hydroxide solution to adjust the pH value of the slurry to 10.3, s...

Embodiment 3

[0082] Make a slurry of bentonite raw ore and water at a solid-to-liquid weight ratio of 1:6, soak it in a container, stir it with a stirrer for 0.5 hours, let it stand for 8 hours, and extract the slurry within the upper 10cm of the container by centrifuging and drying to remove large Particle impurities to obtain montmorillonite to be purified.

[0083] The montmorillonite to be purified and water are made into a suspension liquid with a solid-to-liquid weight ratio of 1:100, 0.8% mass fraction of sodium carbonate is added, and diluted sodium hydroxide solution is added to adjust the pH value of the slurry to 10.5. / min speed centrifugal dehydration to obtain powder I (preliminary purified montmorillonite);

[0084] Make powder I and water into a suspension with a solid-to-liquid weight ratio of 1:100, add diluted sodium hydroxide solution to adjust the pH value of the slurry to 10.5, stir at a stirring speed of 5000r / min for 20min, and then use 80W ultrasonic vibration powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com