Automatic adhered-carton flattening device and application of same

A carton, automatic technology, used in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of slow speed, difficult quality assurance, low production efficiency, etc., to achieve high efficiency, stable operation, and rapid action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

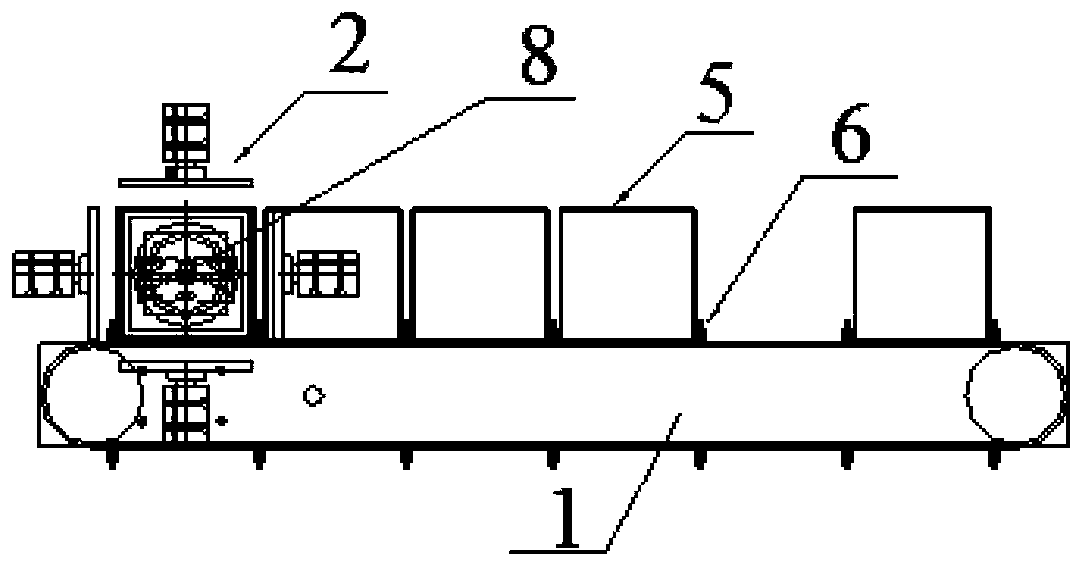

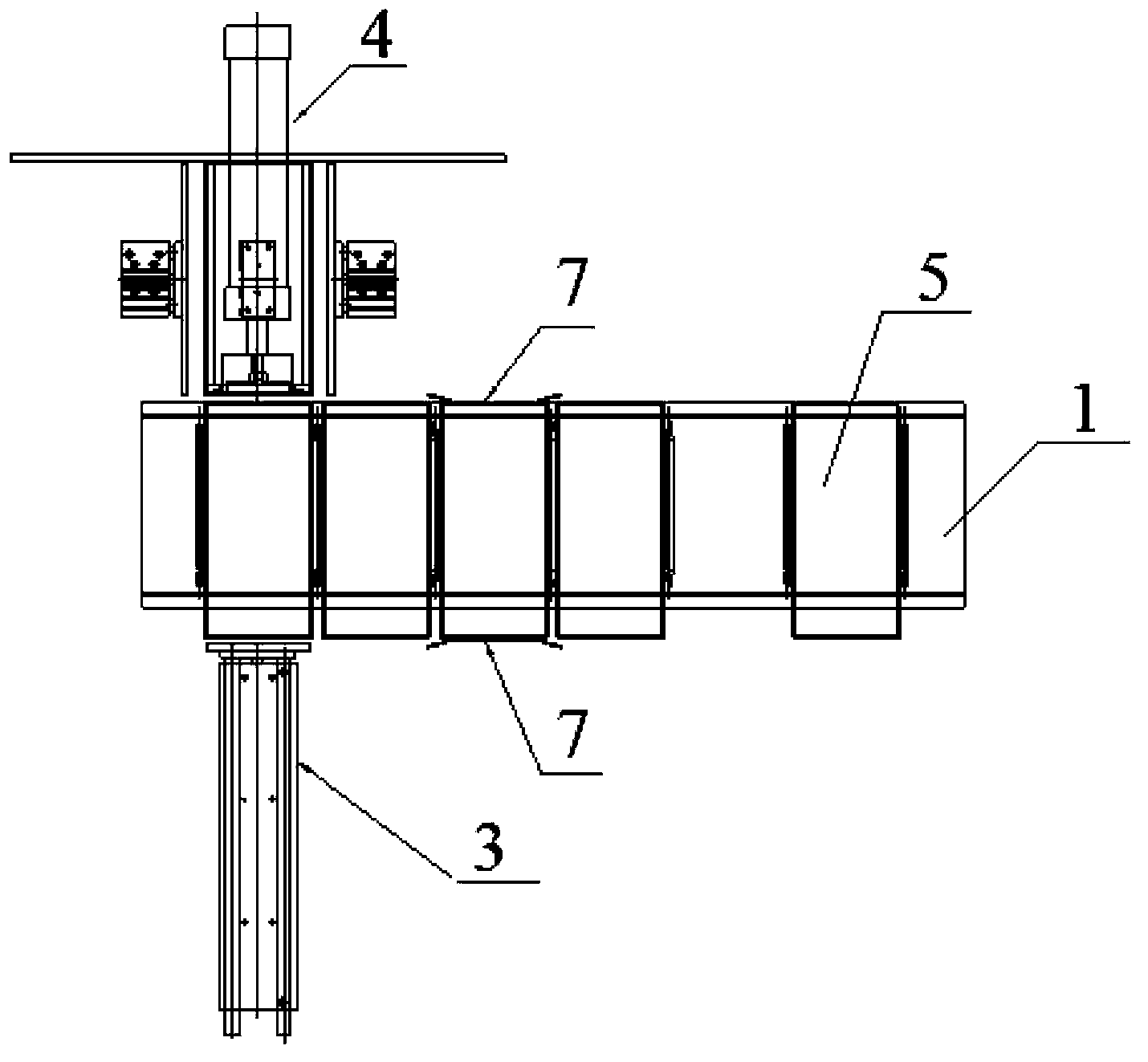

[0022] A kind of automatic paper box lamination after the flattening device, such as figure 1 and figure 2 As shown, the device includes a servo conveyor belt 1, a box pushing mechanism 3, a box mold 8, 4 side flattening mechanisms 2, a carton ejecting mechanism 4, a photoelectric sensor and a controller, and a servo conveyor belt 1 , box pushing and surface pressing mechanism 3, side flattening mechanism 2, carton ejecting mechanism 4 and photoelectric sensor are linked with the controller, the photoelectric sensor is set on the side of the servo conveyor belt 1, box pushing and surface pressing mechanism 3 is set on one side of the servo conveyor belt 1, the box mold 8 and the carton ejection mechanism 4 are set on the other side of the servo conveyor belt 1 in turn, and the box pushing and pressing mechanism 3, the box mold 8 and the carton The ejection mechanisms 4 are arranged in a straight line, and the four side flattening mechanisms 2 are respectively arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com