Dust absorption sand-vibrating machine

A technology of sand vibrating machine and dust suction port, applied in the field of dust vibrating sand machine, can solve the problems of affecting air quality, difficult to discharge dust, affecting physical health, etc., and achieve the effect of ensuring quality and avoiding physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

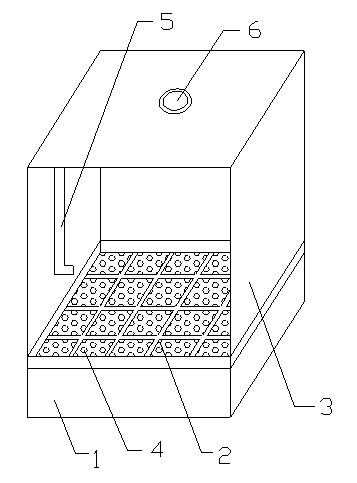

[0016] see figure 1 , the vacuum sand vibrating machine of the present invention includes a base 1, a base 2 and a protective cover 3, wherein the base 1 is located at the bottom and is hollow inside, the base 2 and the protective cover 3 are located above the base 1 and the protective cover 3 is located on the machine On the periphery of the seat 2, the protective cover 3 has only one side opening.

[0017] The base 2 is provided with a plurality of mesh holes 4 .

[0018] A pipeline 5 is connected to the inner wall of the protective cover 3 , and the pipeline 5 communicates with the dust suction port 6 on the top of the protective cover 3 .

[0019] After the inner wall of the protective cover 3 is connected with the pipeline 5, the dust generated by the sand vibrating machine can be discharged to ensure the quality of the air and prevent the operator from inhaling too much dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com