Transversely locally thickened plate strip and manufacturing method thereof

A technology for thickening plates, plates and strips, applied in the direction of metal rolling, etc., to achieve the effect of improving bearing capacity, high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

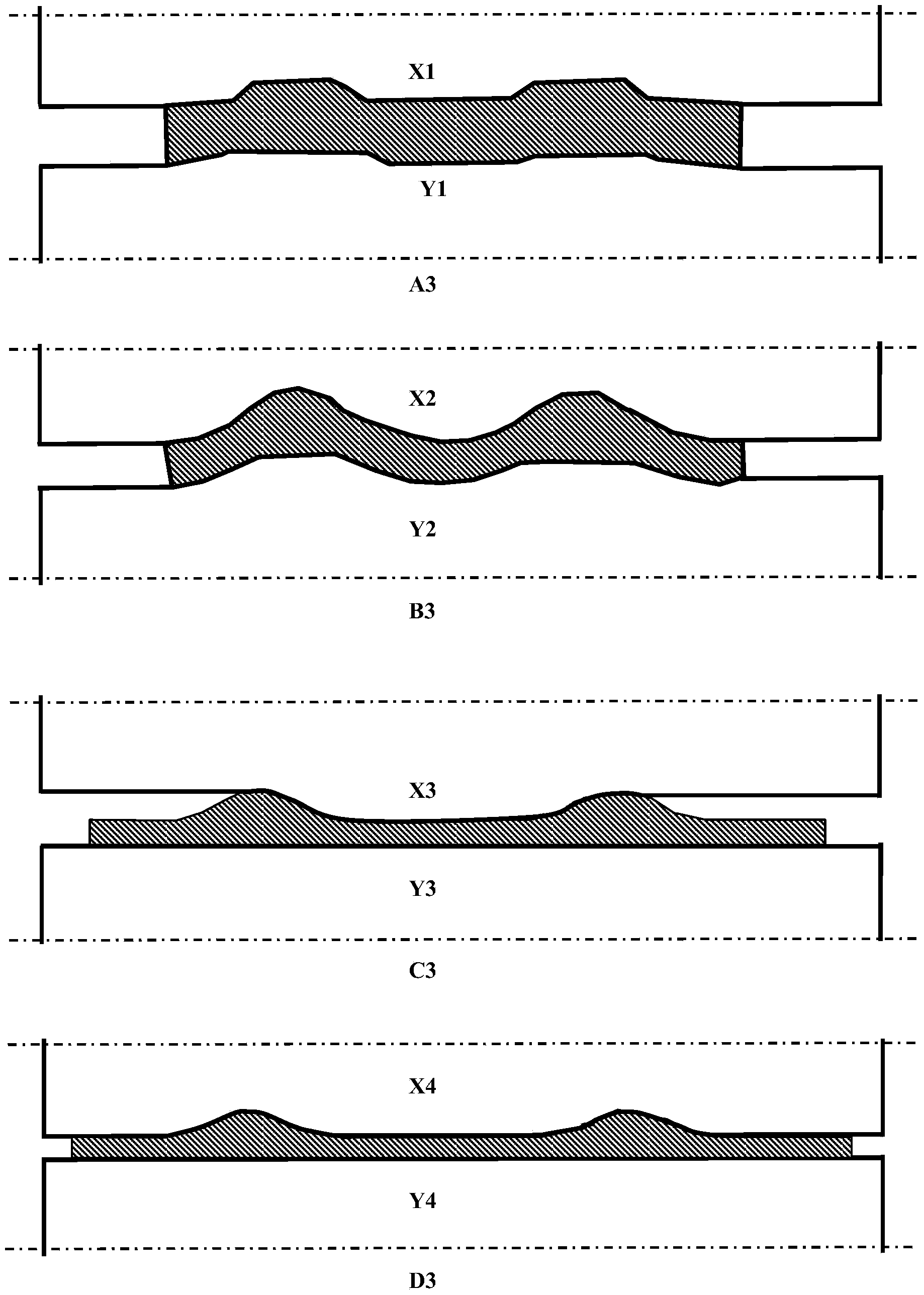

[0034] Select cold-rolled steel strip as the plate and strip to be rolled;

[0035] Use the first rolling mill to carry out the first rolling of the plate and strip to be rolled; a trapezoidal groove is provided on the circumference of one work roll cylinder of the first rolling mill, and a trapezoidal groove is provided on the circumference of the other work roll cylinder. Trapezoidal bulge, the roll gap of the work rolls of the first rolling mill forms a U-shaped curve structure; after the first rolling pass, a rolled plate and strip are obtained, and there is a trapezoidal bulge on one surface of the primary rolled plate and strip , there is a trapezoidal groove on the other surface; the height of the trapezoidal protrusion is 0.1mm, and the depth of the trapezoidal groove is 0.1mm;

[0036] The second rolling mill is used to carry out the second pass rolling of the first-rolled plate and strip; an arc-shaped groove is provided on the circumference of one work roll cylinder...

Embodiment 2

[0043] Adopt cold-rolled steel strip as the plate and strip to be rolled; method is the same as embodiment 1, and difference is:

[0044] There are 2 trapezoidal grooves on the circumference of one work roll cylinder of the first rolling mill, and 2 trapezoidal protrusions are provided on the circumference of the other work roll cylinder. The roll gap of the work rolls of the first rolling mill forms 2 U Type curve structure; there are 2 trapezoidal protrusions on one surface of the primary rolling strip, and 2 trapezoidal grooves on the other surface; the height of the trapezoidal protrusions is 0.2mm, and the depth of the trapezoidal grooves is 0.2mm ;

[0045] The circumference of one work roll cylinder of the second rolling mill is provided with 2 arc-shaped grooves, and the circumference of the other work roll cylinder is provided with 2 arc-shaped protrusions. The roll gap of the work rolls of the second rolling mill constitutes 2 A V-shaped curve structure; there are 2...

Embodiment 3

[0054] Adopt cold-rolled strip steel as the plate and strip to be rolled; Method is the same as embodiment 2, and difference is:

[0055] There are 4 trapezoidal grooves on the circumference of one work roll cylinder of the first rolling mill, and 4 trapezoidal protrusions are provided on the circumference of the other work roll cylinder. The roll gap of the work rolls of the first rolling mill forms 4 U Type curve structure; there are 4 trapezoidal protrusions on one surface of the primary rolling strip, and 4 trapezoidal grooves on the other surface; the height of the trapezoidal protrusions is 0.3mm, and the depth of the trapezoidal grooves is 0.3mm ;

[0056] The circumference of one work roll cylinder of the second rolling mill is provided with 4 arc-shaped grooves, and the circumference of the other work roll cylinder is provided with 4 arc-shaped protrusions, and the roll gap of the work roll of the second rolling mill constitutes 4 A V-shaped curve structure; there ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com