A rail type wall plastering machine

A plastering machine and rail-type technology, applied in the direction of construction and building structure, can solve the problems of troublesome mechanical assembly, inoperability, low efficiency, etc., and achieve the effect of reducing construction cost, reducing manual labor, and improving plastering efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] 1. The present invention is composed of three parts: guide rail system, plastering system and pumping machine.

[0042] 2. The guide rail system is used to lay on the wall, provide plane support for the plastering system and ensure qualified plastering thickness, verticality and flatness.

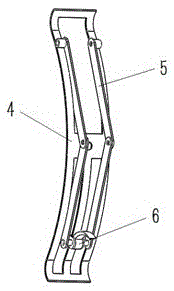

[0043] The plastering system is mainly used for uniform plastering along the direction of the guide rail to ensure the smoothness of the wall surface and the neat and beautiful appearance of the openings and corners of doors and windows.

[0044] The pumping machine is mainly used to transport cement mortar for plastering

[0045] 1) Rail system

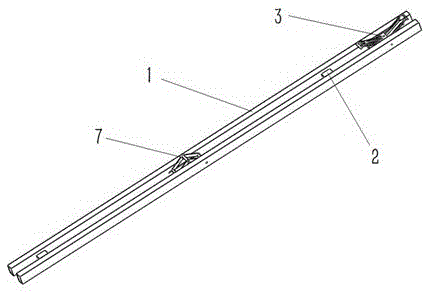

[0046] The guide rail system is mainly composed of three parts: guide rail rods, fixing parts and supporting parts.

[0047] 1. Rail rod.

[0048] The guide rail bar 1 is made of an alloy material with high rigidity, so as to ensure that excessive deformation will not occur under the pressure of the plastering board.

[0049] The guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com