Drainage water saving conversion device

A conversion device and nozzle technology, applied in water supply devices, indoor sanitary piping devices, buildings, etc., can solve problems such as affecting the appearance, inconvenience, and odor, and achieve the effect of convenient conversion, avoiding trouble, and avoiding odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

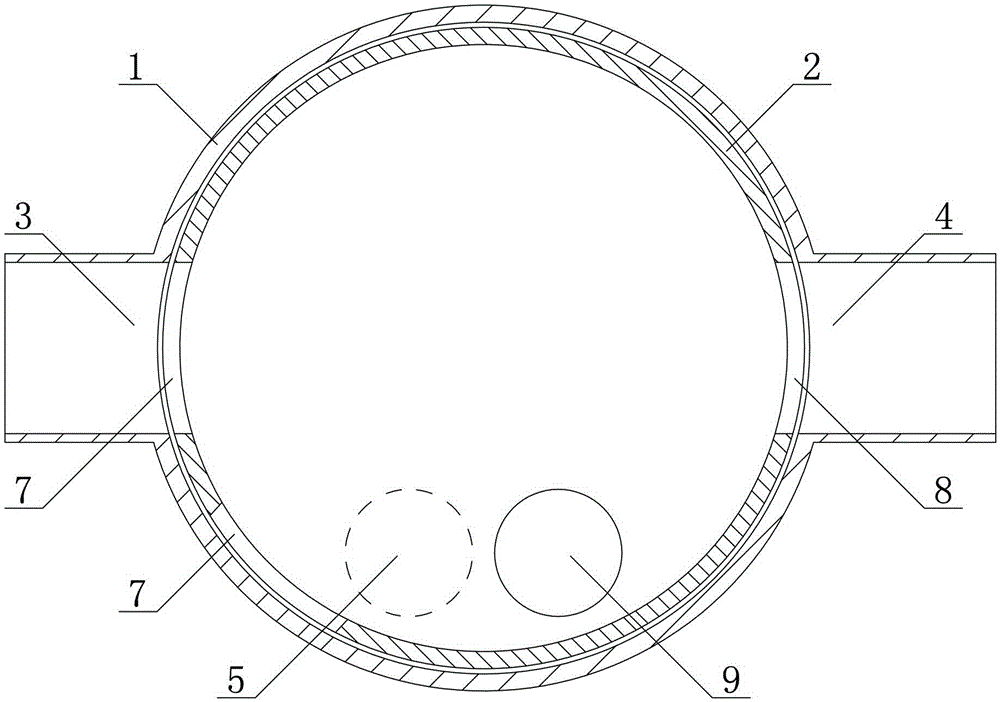

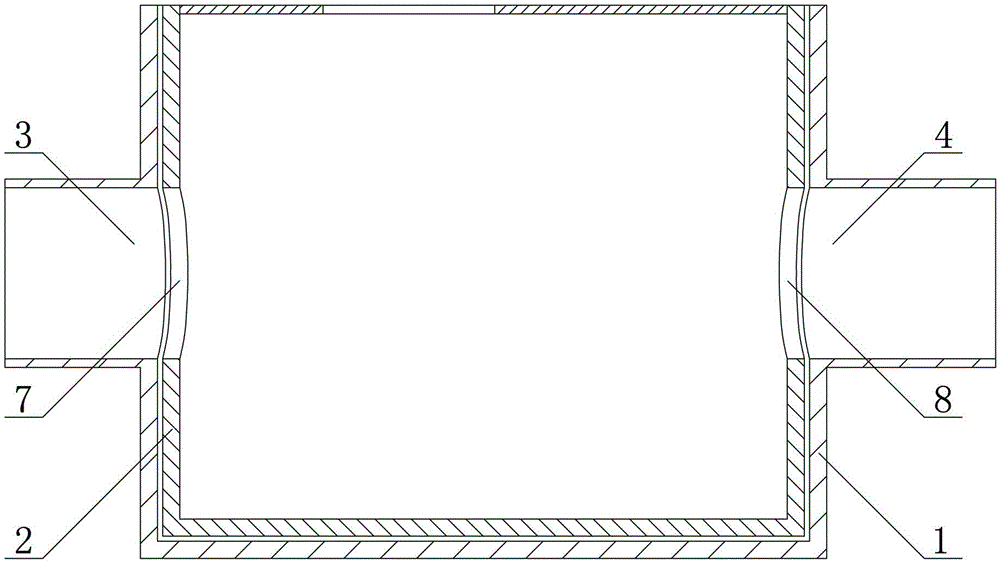

[0027] Such as figure 1 , figure 2 , image 3 As shown, a drainage and water-saving conversion device includes an outer valve cylinder 1 and an inner valve cylinder 2. The outer valve cylinder 1 is provided with an outer water inlet 3, a first outer water outlet 4 and a second outer water outlet 5. The inner valve cylinder 2 is provided with an inner water outlet 6 and an inner water inlet 7; the inner valve cylinder 2 is arranged in the outer valve cylinder 1 and is between the first position and the second position with the outer valve cylinder 1 Rotation fit: in the first position, the inner water outlet 6 is only in communication with the first outer water outlet 4, in the second position, the inner water outlet 6 is only in communication with the second outer water outlet 5, in In the first position and the second position, the inner water inlet is correspondingly communicated with the outer water inlet.

[0028] The specific working process is: connect the outer wate...

Embodiment 2

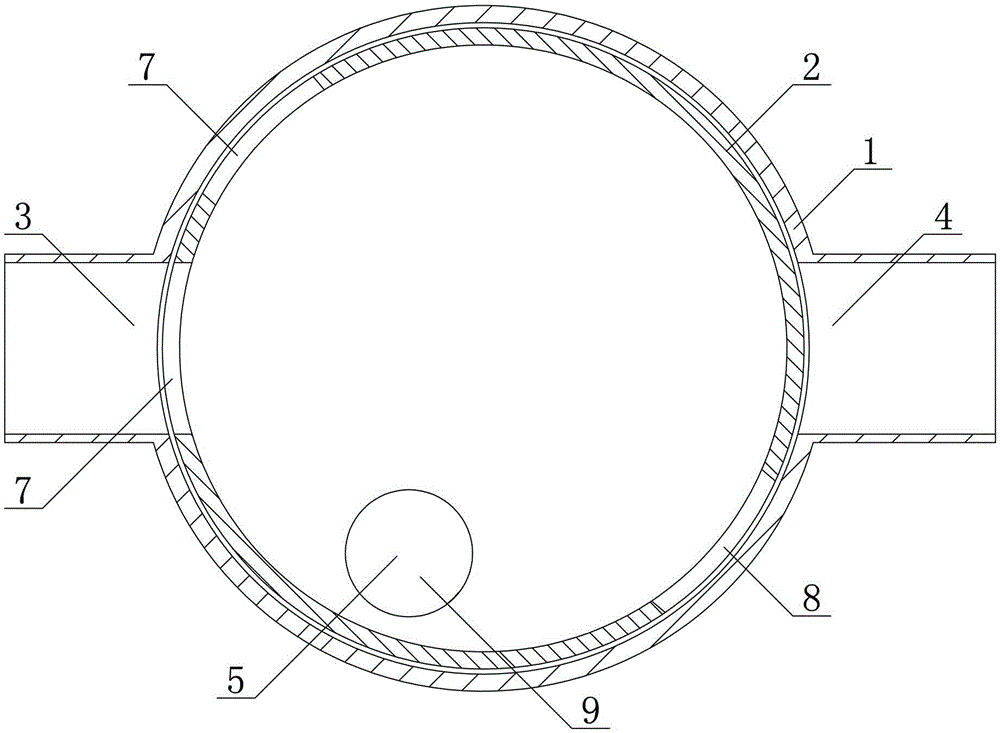

[0034] The difference between embodiment 2 and embodiment 1 is: as Figure 4 As shown, the first outer water outlet 4 and the second outer water outlet 5 are opened on the side wall of the outer valve cylinder 1, and the inner water outlet 6 is opened on the side wall of the inner valve cylinder 2 . In this design, only one inner water outlet is required on the inner valve cylinder 2, which reduces the number of inner water outlets, so that the connection with the first outer water outlet 4 can be realized through only one inner water outlet. and the communication between the second external water outlet 5.

Embodiment 3

[0036] The difference between embodiment 3 and embodiment 1 is: as Figure 5As shown, the first outer water outlet 4 and the second outer water outlet 5 are opened on the bottom of the outer valve cylinder 1, and the inner water outlet 6 is opened on the bottom of the inner valve cylinder 2 . Similar to Embodiment 2, in this design, only one inner water outlet is required on the inner valve cylinder 2, and this design reduces the number of inner water outlets, so that only one inner water outlet can be used to communicate with all The communication between the first outer water outlet 4 and the second outer water outlet 5, and the outer water outlet is located at the bottom is easy for the water to flow downward under the action of gravity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com