A feeding unit in an electronic coil testing machine

A testing machine and coil technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inability to meet international standards, low production efficiency, lack of feeding units, etc., and achieve the effect of automatic intermittent conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

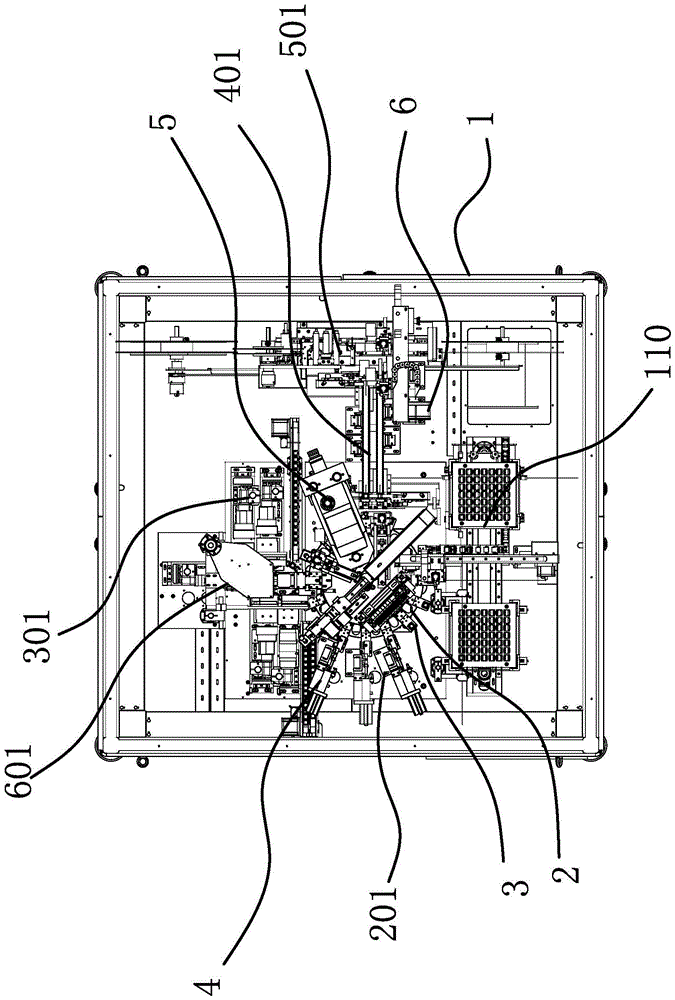

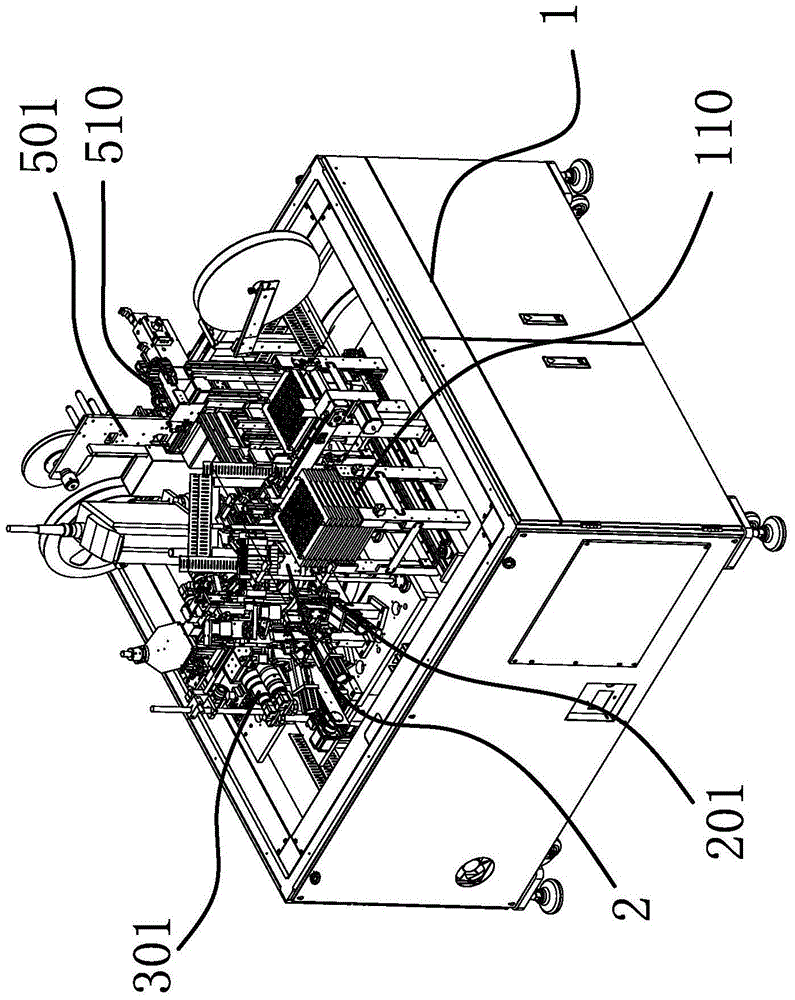

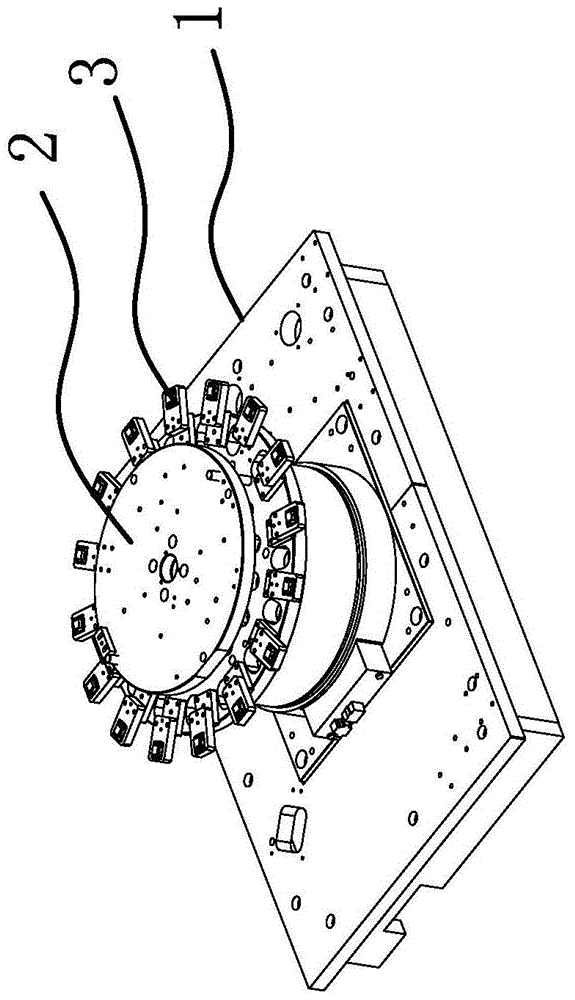

[0025] Such as figure 1 , figure 2 and image 3 As shown, the testing machine includes a frame 1, and the frame 1 is provided with a horizontally rotatable index plate 2, and the index plate 2 is sequentially provided with several fixture tools for positioning the target workpiece 7 along the circumferential direction. Position 3, rack 1 is sequentially provided with a loading unit 110 for delivering the target workpiece 7 to the jig station 3, an electrical test unit 201 for performing electronic performance tests on the target workpiece 7, and an electrical test unit 201 for the above-mentioned The sorting and unloading unit for rejecting the target workpieces 7 with unqualified electronic performance test results 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com