a slicer

A slicer and slicing device technology, which is applied in metal processing and other directions, can solve problems such as poor taste, loss of nutrients, and high extrusion force of food materials, so as to avoid molecular structure damage, less loss of nutrients, and small extrusion force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

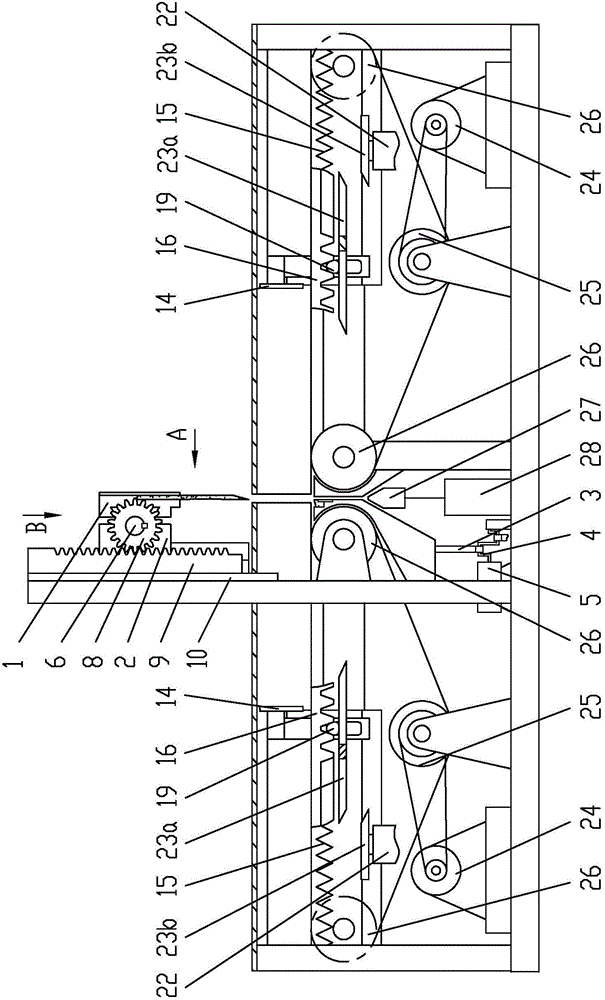

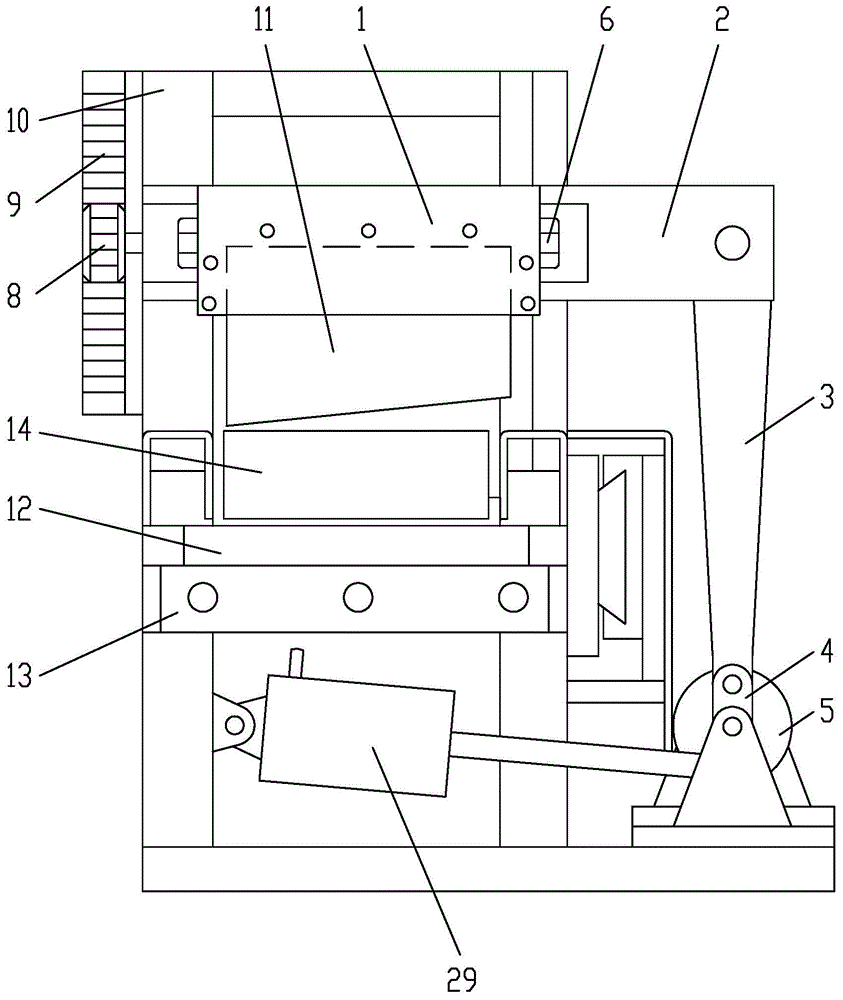

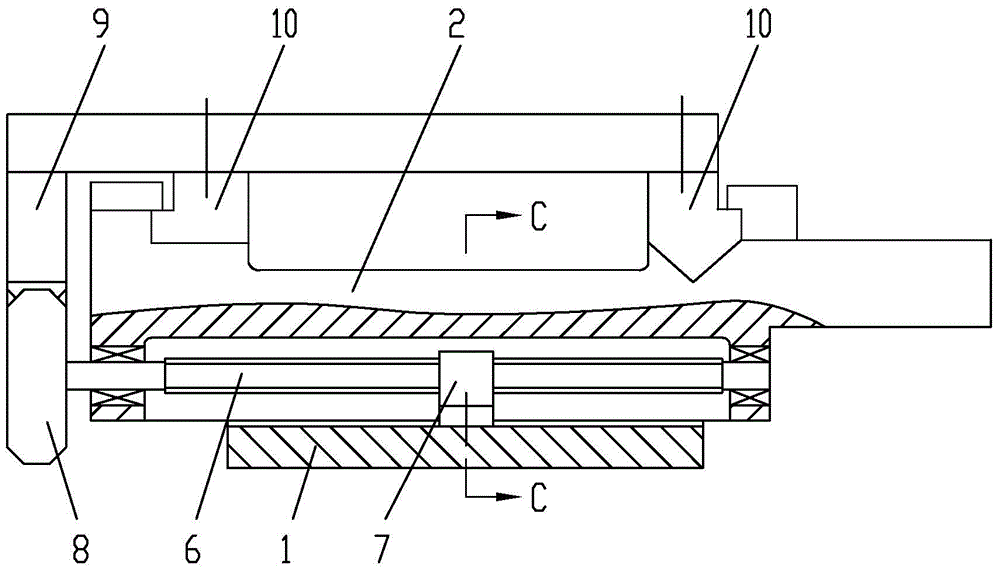

[0025] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 , a slicing machine, including a slicing device and a control system, the slicing device includes a vertical guide rail pair, a horizontal guide rail pair and a cutter mounting seat 1, and the vertical guide rail pair is composed of a triangular guide rail and a rectangular guide rail to form a combined guide rail pair The closed guide rail structure, the horizontal guide rail pair is a dovetail guide rail pair, and an adjustable insert 2a is provided between the cutter mounting seat 1 and the matching dovetail structure of the horizontal support guide rail 2 to adjust the gap of the matching dovetail structure. Ensure that the cutter mounting seat 1 moves smoothly; the cutter mounting seat 1 is fixedly connected with a movable blade 11 with an inclined edge, and when the movable blade 11 cuts and feeds, the edge of the movable blade 11 is installed toward the cutter The horizontal m...

Embodiment 2

[0030] Example 2, see Image 6 , the locking mechanism includes a movable tongue 19 and a fixed tongue 20 arranged on the auxiliary moving guide rail of the third linear guide rail, and the movable tongue 19 and the fixed tongue 20 form a caliper shape; the movable tongue 19 is located in the horizontal section Below, there is a part of the caliper that stretches into the movable stop tongue 19 and the fixed stop tongue 20 on the width direction of the horizontal section of the conveyor belt 16; Sliding fit structure, a tongue spring 21 is connected between the movable tongue 19 and the chute bottom of the auxiliary moving guide rail of the third linear guide rail, and the tongue spring 21 is used to keep the movable tongue 19 away from the conveying belt in the height direction 16 horizontal sections, the other side of the movable tongue 19 is provided with a push rod electromagnet 22, and the push rod electromagnet 22 is used to push the movable tongue 19 toward the fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com