Testing method of oil well downhole rapid testing system

A technology of testing system and testing method, which is applied in the direction of wellbore/well components, measurement, earthwork drilling and production, etc., can solve problems such as inability to diagnose, and achieve the effect of simple operation, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

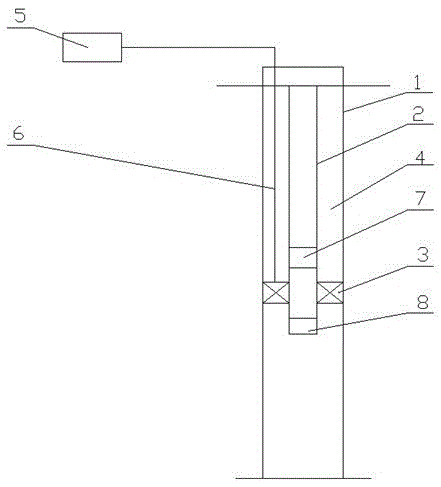

[0030] like figure 1 As shown, the present invention provides a quick downhole test system for oil wells, comprising a casing 1, a test string 2 that is lowered into the casing, the bottom of the test string is sealed and isolated to form a closed body, and the gap between the test string and the casing is The annulus 4 between the test pipe string and the casing is sealed by the hydraulic packer 3, and the hydraulic packer is pressurized by the surface hydraulic pump 5 through the hydraulic pipeline 6 to realize the sealing. A downhole quick switch 7 is installed on the test string, and a storage pressure gauge 8 is installed at the bottom of the test string.

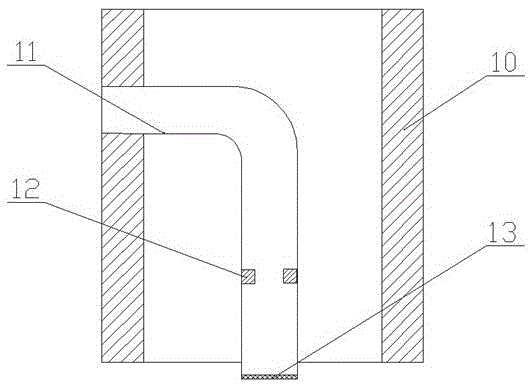

[0031] like figure 2 As shown, the downhole quick switch includes a switch outer cylinder 10, and a flow-limiting thin tube 11 is arranged inside the switch outer cylinder. The controller 12, the bottom of the capillary is sealed 13 by a thin film.

Embodiment 2

[0033] like figure 1 As shown, the present invention provides a quick downhole test system for oil wells, comprising a casing 1, a test string 2 that is lowered into the casing, the bottom of the test string is sealed and isolated to form a closed body, and the gap between the test string and the casing is The annulus 4 between the test pipe string and the casing is sealed by the hydraulic packer 3, and the hydraulic packer is pressurized by the surface hydraulic pump 5 through the hydraulic pipeline 6 to realize the sealing. A downhole quick switch 7 is installed on the test string, and a storage pressure gauge 8 is installed at the bottom of the test string.

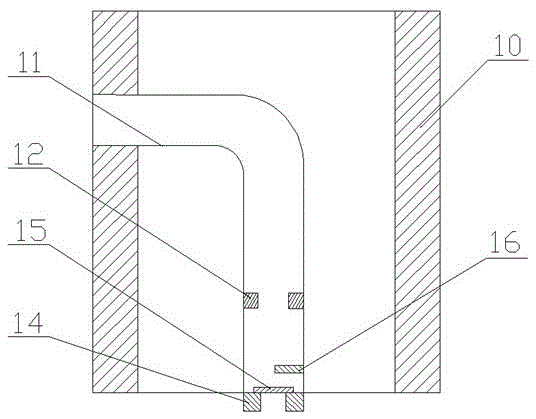

[0034] like image 3 As shown, the downhole quick switch includes a switch outer cylinder 10, and a flow-limiting thin tube 11 is arranged inside the switch outer cylinder. Controller 12, a magnet ring 14 is installed at the bottom of the flow-limiting capillary, and the magnet ring is connected with a movable iron p...

Embodiment 3

[0037] Embodiment 3 Oil well downhole rapid test method

[0038] During the well testing process, the first step is to run the test string into the reservoir at a certain depth; before isolation, the wellbore has fluid flowing out through the annular space, and the bottomhole pressure at this time is not too high, for example, when the formation pressure is 10Mpa , the pressure in the flow process is only 6Mpa;

[0039] In the second step, the surface booster pump pressurizes the packer through the hydraulic pipeline during the test. When the packer pressure reaches the packer pressure, the packer seals the annulus between the test string and the casing;

[0040] In the third step, after isolation, the formation fluid will continuously collect into the wellbore, and the pressure will gradually increase during the collection process, for example, from the initial 6Mpa to 10Mpa, and then continue to rise;

[0041] In the fourth step, the downhole quick switch is turned on; when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com